Dyndrite, UPM Work to Bring Data Intelligence to Metal 3D Printing Build Plates

The collaboration aims to reduce print failures and enable reliable supply chain for additive manufacturing production.

Share

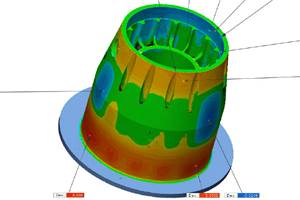

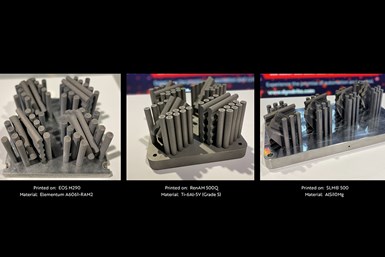

Dyndrite showcases parametrically created ASTM qualification build plates for major LPBF platforms. It provides materials and process development scientists and engineers with toolpath control. Photo Credit: Dyndrite

Dyndrite and United Performance Metals (UPM) Additive Solutions are collaborating to bring intelligence to critical, yet often ignored 3D printing components. The companies will work together to capture and provide the data that unlocks the variables to build plate life, and bring supply chain predictability and reliability to new and resurfaced build plates.

Dyndrite is a provider of the core Accelerated Computation Engine (ACE) and Application Development Kit (ADK) which is used to create digital manufacturing hardware and software. UPM Additive Solutions is a supplier of metal build plates for the additive industry. The companies are bringing together their expertise to create “smart” metal build plates for the 3D metal printing industry.

The partners say the build plate is an integral component in metal 3D printing because it lays the foundation for every part being built. Unfortunately, most users in the space do not record key data that can unlock the unknowns concerning the life cycle and history of their build plates. Without this information, for example, laser powder bed fusion (LPBF) users face an increased risk of powder leveling issues, internal fatigue and plate warpage that can lead to lost time and costly build failures.

“UPM is excited to partner with Dyndrite and its metal users to unlock the keys to build plate life,” says Chris Prue, applications development manager at UPM Additive Solutions. “Through data, we can put knowledge in the hands of the user to raise throughput and reduce failures. Build plate usage data helps customers understand and manage their usage, and demand for plates to keep costs low while keeping inventory available to reduce downtime. Through smart build plates and a reliable supply chain, we can collectively mature and grow the industry.”

The partners say the AM industry must develop new tools to enable the industry to scale. “ By working with UPM and leveraging the power of machine data we can accelerate learning, improve predictability and grow,” says Harshil Goel, Dyndrite founder and CEO. “Through insights of the data, we allow users to make less risky decisions on their build plates to assure success.”

UPM currently offers subscription-based services to track build plates from initial manufacture to customer and through its refurbishment. Each plate is serialized and maintains accessible quality inspection data. Smart Build Plate customers can view build data associated with each plate from the machine (preheat, laser power, powder melted, heat treatment, stress relief) along with other conditions to which the build plate will be exposed. The UPM Smart Build Plate service will support all major metal 3D printer OEMs, including Aconity, EOS, Renishaw and SLM Solutions, and is expected to roll out in Q3 2023.

- Learn more about United Performance Metals’ work as a one-stop build plate shop for production AM. The company offers full refurbishment and inventory management for this critical additive supply.

- Read about President Biden’s announcement for the AM Forward additive manufacturing initiative which he discussed during a visit at United Performance Metals in Cincinnati, Ohio.

- Take a look at this post about Dyndrite’s collaboration with AMFG for cross-platform 3D metal automated production. AMFG powered by Dyndrite is an integrated solution that is said to unlock the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks and streamlining the entire production process for increased efficiency and cost savings.

Related Content

How Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)