3D Printed Metal Parts Go Hypersonic at Zero MPH

Purdue Researchers are using additively manufactured injector components from Velo3D to create Mach 6 conditions for a ground-testing facility.

Researchers partnered with Velo3D to print fuel injectors with complex geometries that achieve very high fuel-air mixing performance. Photo Credit: Velo3D

Researchers at Purdue University are demonstrating that advanced additive manufacturing (AM) technology is now capable of producing fully dense, end-use parts with robustness that surpasses traditional methods such as casting for parts that can create hypersonic conditions.

“Supersonics” denotes aircraft that break the sound barrier at Mach 1 (like the now-retired Concord and the up-and-coming Boom Supersonic), and extends to around Mach 5, which is five times the speed of sound and more than 3,500 mph at sea level.

“There’s a line you cross at around Mach 5,” says Carson Slabaugh, Purdue associate professor. His 20-person team at Zucrow Laboratories has been studying high-speed combustion systems since he started his lab at Purdue in 2015. “When a vehicle flies that fast, extreme compression and heating of the air flowing around and within the fuselage occurs. At Mach 5, it’s about a six-fold increase in the temperature and a pressure increase of a few hundred times. That kind of thermal and mechanical loading causes the regime of aerodynamics and thermodynamics and structural mechanics to completely change compared to lower speed systems.”

Above Mach 5, the temperature of atmospheric air as it rushes by is thousands of degrees and the pressure is several hundred psi. The air itself can even become chemically reactive, if you fly fast enough. These extreme flow conditions become a challenge to any vehicle-propulsion system whose thrust comes from burning fuel.

The team at Zucrow Labs is focused on learning everything possible about the critical turbulent (reacting) flow physics that must be accounted for when an engine reaches hypersonic speeds.

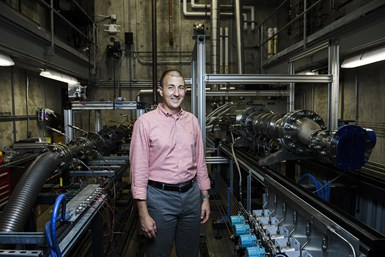

Associate Professor Carson Slabaugh (pictured) and his team are using 3D printed parts in a test rig that duplicates the hypersonic environment without ever leaving the ground. Photo Credit: Velo3D

To meet this challenge, Slabaugh and his team partnered with Velo3D to ‘print’ fuel injectors with complex geometries that achieve very high fuel-air mixing performance. The parts could not have been made with conventional fabrication methods, especially not with the high-temperature, high-strength metal superalloys needed to survive the extreme testing conditions. The teams worked together to rapidly prototype the Purdue team’s designs for testing, evaluation and design iteration. Slabaugh and his team then used the data from the prototypes to scale up their designs into a full-scale system, which Velo3D also manufactured.

“Through our partnership, we helped Velo3D to understand the design requirements for high-speed combustion systems and they taught us how to better design for additive manufacturing,” Slabaugh says. “This is the sort of mutually beneficial relationship we build with industry partners as we solve the challenges associated with advanced technology transition.”

Flight testing these systems is expensive, and has major limits on what can be actually measured for research purposes. Engineers lean heavily on earthbound solutions to develop new technologies while keeping costs in check. They are recreating the conditions experienced during hypersonic flight and proving-out engine components in ground-test facilities — such as the one at Purdue for which Slabaugh’s team is building a rocket that will never leave Earth.

“We engineer components that will experience hypersonic environments while going zero miles per hour and staying bolted to the ground,” he says.

For some time now, advanced computer simulation software has been a valuable tool for engineers who need to explore the relationship between complex physics and physical structures. Methods such as computational fluid dynamics (CFD) and fluid-structure interaction (FSI) can be used to simulate material and structural behavior in response to the flow of air or liquid, enabling engineers to optimize their designs before ever manufacturing anything.

But hypersonics turns out to be extremely unpredictable, defeating even the most sophisticated computer-simulation capabilities. “One fundamental problem is that we can’t reliably predict the flow and flame conditions within the engine at hypersonic conditions,” Slabaugh says. “Reacting, turbulent-flow is extremely complicated to model with CFD. We’re at such extreme levels of turbulence and flow conditions that we just can’t capture everything that happens as the flame evolves.”

According to Slabaugh, the computational power needed to analyze even the smallest part of this engine is hugely expensive and the end result is that many simplifying assumptions must be made for integrated design analysis. Evaluating these assumptions and their effect on model accuracy is a key theme of Slabaugh’s work.

This is where 3D printing delivers a faster solution for hypersonics-worthy parts. It enables engineers to leave simulation behind and go back to the real-world, classic, manufacturing paradigm of “build and break” (or build and burn, in this case). With a twist this time — using advanced metal AM for the “build” part of the equation.

“With VeloLO3D, we’re designing the injectors for that combustor to produce very specific turbulent flow fields that mix fuel at a certain rate and allow us to stabilize a very powerful flame in a very compact volume,” Slabaugh says. “This creates the conditions for all the things we’re going to test downstream.”

This is where AM is proving its worth for the “build and burn.” The ability to quickly 3D print a variety of injector geometries for the test combustor — in this case made out of Hastelloy X, one of the few high-strength, high-temperature superalloys that can withstand the hypersonics environment — enabled the Purdue team to rapidly identify which design worked best.

For Nick Strahan, a test engineer working on Slabaugh’s team, the experience of using AM was an eye-opener. “We had essentially approached this problem with traditional subtractive manufacturing techniques in mind before,” he says. “But there were some features in our design that would have limited the performance of the combustor — and doing it additively with Velo3D instead enabled us to integrate our unique geometry much more easily.”

Using traditional subtractive manufacturing would have meant casting individual parts, which requires long, drawn-out cycles of tooling, moldmaking and design iteration. “AM techniques significantly shortened manufacturing lead times as we optimized our designs,” Strahan says.

The engineers subtly varied the flow passages of the injector with five different designs (just a matter of tweaking the STEP data file which the Velo3D Sapphire system’s print-preparation software accommodated automatically), printed them out and ran them through a gauntlet of hypersonic-relevant test conditions.

In just two weeks, the team was able to isolate the highest performer that had all the stationary and dynamic features they were looking for. “We see AM as a powerful tool with which we can bring other creative engineering solutions to complex design problems into reality more quickly,” Slabaugh says.

Now that the single injector design has passed rigorous testing, the aim is to assemble a large array of them into an even more powerful combustor. Velo3D is consulting further with Zucrow Labs to help them take advantage of its build-anything-you-want capabilities — by integrating the injector set into a single piece, 3D-printed component. From there, the engineers will continue to refine and assemble a complete combustor system, aiming for full-scale hypersonic test capability in late 2022.

- Read how Launcher is using additive manufacturing from Velo3D to optimize satellite design.

- Learn about Aerojet Rocketdyne’s use of metal 3D printing technology from Velo3D to make a critical flight component lighter, smaller and much less expensive than its predecessors.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read MoreCan the U.S. Become Self-Sufficient in Aerospace Alloy Metal Powders?

6K’s technology can upcycle titanium and nickel-alloy parts into additive manufacturing powder. Here is how the circular economy helps national security.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)