Velo3D Debuts 8-Laser Machine for Parts This Size and Bigger

Sapphire system scales up — see the new machine along with examples of large metal parts 3D printed in one piece.

Share

Read Next

For powder-bed additive manufacturing machines, size opens the way to productivity. A larger build volume offers the chance to produce an increased quantity of parts efficiently by grouping more of them into the build. However, another advantage of size is … size! Bigger parts can be made in one piece through AM thanks to bigger machines.

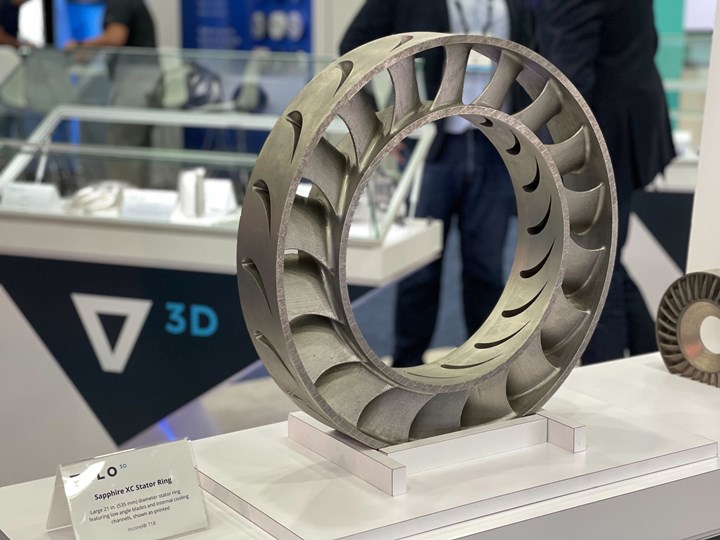

This part is an example. The 21-inch-diameter Inconel 718 stator ring with internal cooling channels was made on Velo3D’s Sapphire XC. This metal AM system is capable of producing parts 600 mm in diameter by 550 mm in height, and also features 8 lasers for high throughput. The Sapphire XC system, the first unit of which shipped to SpaceX in December 2021, is making its public debut in Velo3D’s booth at IMTS in 2022.

Like previous Sapphire machines, the new larger model includes control features aimed at minimizing the need for support structures. The stator blade illustrates this. Its low-angle blades were printed without supports despite the overhang they presented during printing. Other never-before-seen parts in the Velo3D booth were also made on the new Sapphire XC.

This 21-inch Inconel stator ring was produced on new larger-size Sapphire powder bed fusion machine. Photo Credit: Velo3D

Related Content

-

AM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

-

Aluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

-

World’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

.png;maxWidth=300;quality=90)