Sustainability is a major issue right now, and additive manufacturing is at the forefront of these conversations often, but not always rightly so. According to my cohost, Stephanie Hendrixson, one factor affecting the perception of AM is greenwashing, or the idea that something is more sustainable than it actually is. While additive manufacturing does provide opportunities for recyclable materials, lightweighting and reduced waste, true sustainability is much more complex — it requires companies to look at a product’s entire lifecycle.

So what are the considerations for designing sustainable parts and production processes? And which companies come nearest to the ideal of the circular economy? Stephanie Hendrixson and I discuss sustainability and additive manufacturing on the latest episode of the AM Radio podcast. Listen above, or read on for the transcript and notes.

Transcript

Stephanie Hendrixson

The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo, the leading industry event focused on 3D printing for production. The conference takes a practical, applications-based look at the machines, materials and methodologies being used to create end-use tools and components. The event is designed for owners, executives and engineers in manufacturing as well as OEMs involved in durable goods production. Join the Additive Manufacturing team in Cincinnati, Ohio for two days of in-depth conference sessions, exhibits and plenty of networking opportunities with AM experts. Also, on the expo floor, check out the finalist entries in The Cool Parts Showcase, a contest to find the next subjects of our video series, The Cool Parts Show. Be sure to vote on your favorite. The Additive Manufacturing Conference and Expo runs October 12 through 14th. Find all the details and register at AdditiveConference.com.

Julia Hider

So, Stephanie, one thing you’ve written about a lot is sustainability and additive manufacturing. And I wanted to talk a little bit more about that today. So just to start off, why is this a common topic in additive manufacturing? Because it’s not something that is talked a lot about in other forms of manufacturing.

Stephanie Hendrixson

Yeah. So it kind of depends on what your definition of sustainability is. So a lot of people, and this was me included when I started writing about this, associate sustainability with recycling, which is part of it. But that’s not the the entire concept. And so if you look at another industry, like plastics manufacturing, they talk a lot about recycling because the industry is just under pressure, like a lot of the waste that we can, we can see in the ocean or as litter is plastic. I think additive gets aligned with sustainability in part because of this idea of greenwashing, which is sort of like the false impression that something is more sustainable or green than it actually is. And so if you’re coming at it from more of a conventional manufacturing perspective, maybe like machining, where you can very visibly see all the chips that are flying off, you see all the waste that’s coming off, and then you look at a 3D printer that’s just applying the minimal amount of material, just the material that you need, it ends up looking like a much more sustainable process. And it can be and it often is, but it’s, it’s really case by case dependent. It depends on what you’re making, how you’re making it. There definitely still is waste generated in the additive manufacturing process. It’s pretty easy for an additive company to say, “Well, we’re sustainable, we use recycled material, we use recycled filament or something like that.” But you also need to look at what is the process that they're using. What waste are you making? What’s the product? So is this something that’s going to go into the world and will be used just once and get thrown away? Or is it something that is going to help? You know, is it going into an electric vehicle or something that’s going to make the world as a whole more sustainable? And then you know, what happens to it at the end of its life? Is this something that you can recycle? Is this something that you can reuse? Or is it going to be headed to a landfill?

Julia Hider

You touched on recycling a few times in there, and like you said, one of the most common things that people want to talk about is recycled materials. So what types of materials in additive manufacturing can be recycled? You know, you mentioned plastics is the most common one, is it possible to recycle metals or other materials?

Recycled Materials

Stephanie Hendrixson

Yeah, so there are a lot of materials that are using 3D printing that can be recycled. Metals are actually pretty efficient to recycle. Recycling the end use product is pretty, is pretty common. But if you’re using like a powder bed fusion process, you can reuse that powder over and over. It does, it does change over time, it’s sort of as it gets exposed to oxygen, the, the chemical composition can change. And so a lot of companies will mix their previously used but not sintered powder with new material. There are some other companies, like 6K has a process to recycle metals into additive powder. So there are people kind of looking at ways of recirculating and reusing those materials. On the polymer side, there is a lot of recycling happening. But the material has a tendency, depending on what type of plastic it is, it has a tendency to sort of degrade. And so there are limits on how many times you can recycle it. In some cases, actually, the properties improve, but it’s really, really material dependent. But recycling doesn’t have to be the end of the line for some of those materials. Things like PLA are actually compostable if you can get them into an industrial composting environment. So recycling is a great end use for some of these materials. But it’s not the only way to do something sustainable.

Julia Hider

So something I’ve always wondered about is a lot of these materials can’t be recycled forever. But how do companies keep track of how many times something has been recycled already?

Stephanie Hendrixson

As far as tracking, you know, it sort of depends whether it’s process waste, like something that’s happening in your facility that you can sort of keep control over or something that’s going out into the world that you’re having to recapture. I know companies have a lot of different methods for this. Obviously, you can put labels on it, you can put QR codes and things like that, barcodes, to track it. If it’s something that’s going out into the world, it’s a little bit more difficult. I haven’t seen a whole lot of solutions on that front. The one company that comes to mind is a California company called MolyWorks. And they are working on a mobile metal recycling solution. And they also print metal parts. And so one of the challenges that they had to face early on is that when you’re trying to recycle scrap into metal powders in their case, you really need to know what your input is to be able to control the output. And so they have to be really careful about figuring out what the chemical composition of the material is. And so now, when they print parts out of material that they know, they’ll print a QR code in it that tells them exactly the the makeup of that material so that when that part eventually comes back to them or comes back to some other recycling, recycling facility, they can very easily identify what it is and know how to recycle it the best.

Julia Hider

So I think that design plays a lot into sustainability and additive manufacturing. So if a manufacturer is looking to design a sustainable part, what design factors would they keep in mind?

Assembly Consolidation

Stephanie Hendrixson

So the design, it has to do with manufacturing, but it also has to do with what the part actually is, where it's going. So in the manufacturing process, doing things like lightweighting that part through topology optimization are going to reduce the weight of it. You’re gonna make it more efficient in use, probably, but they’re also going to allow you to use less material in the manufacturing process. So you’re consuming less, it’s a little bit more sustainable in that sense. Oftentimes, in additive manufacturing, we see people doing things like assembly consolidation, where you’re able to take a couple of different parts that previously would have been like welded together, or assembled together with fasteners, and print them as just one piece. That’s a really great use of additive in terms of sustainability, because the fewer materials you can use, the easier that product is going to be to dismantle later and to recycle. And so if you can eliminate, you know, screws or other kinds of fasteners, that’s, that’s a win there. You know, I was recently at Sintavia, which is this Florida manufacturer that specializes in metal AM for aerospace parts. And the CEO, Brian Neff, said, said a really interesting thing that often the best fit for additive manufacturing are these larger, more complex components, like those types of assembly consolidations. And those are also usually the cases where additive makes the most sense from a sustainability perspective, where you’re getting the, the best efficiency and the lightest weight, and all those other advantages in the end use part. So it’s really, it’s a combination of your manufacturing process, and where that part is eventually going to end up in the world.

What to Consider for Sustainable Manufacturing

Julia Hider

Yeah, so production processes. What would a manufacturer consider when designing a sustained, sustainable additive manufacturing process?

Stephanie Hendrixson

So I guess the best-case scenario would be either to be the OEM, or to be able to work really closely with the OEM, because sustainability is maybe not an all-inclusive term. The term that I like to talk about is, is the circular economy because that sort of describes what the end user, what the end goal should be, where you’re, you’re taking material, you’re producing a part, it’s doing something in the world, and then it’s coming back to the source or the material is getting recaptured, and it has life beyond that. So if you are in the position of introducing a new product, or being able to think in this circular way, you know, I would start with the material — try and find something that is going to be recyclable, or something that comes from a sustainable source, like a biopolymer, that, that can be composted later. Design for the end function of the part, to make it, to make it efficient, to make it lightweight. That sort of thing translates into things like energy savings and lower fuel consumption. Try and make it with as few materials as you possibly can. And then think through what’s going to happen to that part with that product at the end of its lifecycle. Is this something that your customers can recycle when they’re done with it? Is it something that you can have them send back to you and you can recycle it? You know, don’t just send things out into the world and let them go into a landfill. Think through the best-case scenario, figure out how you can recapture that material and and reuse it in some way.

Circular Economy Examples

Julia Hider

So we’ve talked about a lot of things — what are some companies that have a good working example of circular economy?

Stephanie Hendrixson

So most of the examples I can give you right now are on the polymer side in additive manufacturing. So, and most of them are customer facing as well. So one example would be Aectual, which is this Dutch architecture company. And they are 3D printing things like building facades, and room dividers and acoustic panels. And they mostly use biopolymers. But they’ve sort of leaned into this idea that fashions change, and like human tastes are going to change. And so if you purchase a, you know, some facade pieces from them, and put them on your building, and then in 10 years, you decide, you know, “Actually, I don’t really like this design anymore, the color’s not really working.” You can send those panels back to them, and they will recycle them, reuse the material to make something new. A similar one is Model No. If you’re done with your table or your chair, you can send it back to them. They’re working on processes to kind of grind that plastic back up and make new furniture out of it. Another example that I came across recently that I really like is a company called HILOS, which is making shoes, custom, custom heels. And so the, the base of the shoe, kind of the platform, is 3D printed TPU and then the top is leather. And when you get the shoes, there’s actually a return label right there in the box. And so when you’re done with them, you put them back in the box, you put the return label on, send it back to the company. There, there’s only two or three materials involved, depending on what model of the shoe you get, and so it’s really easy for them to just deconstruct it, split it up into its different pieces. The leather goes off to a leather processing facility, the plastic gets ground up, gets turned into injection molding pellets. So there are a lot of companies that are working on this right now. I hope to see a lot, lot more of them in the future. So if anybody out there listening has any any leads or tips, please reach out. I’d love to hear about it.

Julia Hider

So you’ve written articles about all the companies you just mentioned. Are there any other resources on AdditiveManufacturing.Media where people can learn more?

Stephanie Hendrixson

Yeah, so there’s kind of, like, a microsite on sustainability that we have that has links to a lot of those stories and sort of lays out all the different considerations that you should think about if you’re trying to do a sustainable manufacturing process with additive. We also have an infographic that kind of lays out the five stages of manufacturing and how additive and sustainability can can help each other and work together throughout all of those five stages. So we can leave links to those in the show notes.

Julia Hider

Alright, that’s it for this episode.

Stephanie Hendrixson

AM Radio is recorded with help from Austin Grogan and Kade Nicholson. The show is edited by me, Stephanie Hendrixson, and Alex Lytle. Our artwork is by Kate Billbery. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in the Queen City, Cincinnati, Ohio. Learn more at AdditiveManufacturing.Media.

Related Content

Multimaterial 3D Printing with Conventional Powder Metallurgy

Unbound sand serves as temporary, reusable molds for metal powders in Grid Logic’s 3D printing process.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreCan the U.S. Become Self-Sufficient in Aerospace Alloy Metal Powders?

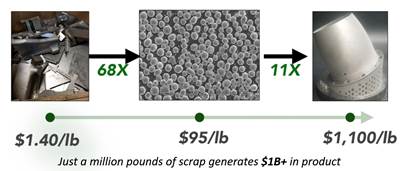

6K’s technology can upcycle titanium and nickel-alloy parts into additive manufacturing powder. Here is how the circular economy helps national security.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

Is Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read MoreCustom Heels Are a Step Up for Circular Fashion, Sustainable Manufacturing

Custom shoe company Hilos demonstrates how, with additive manufacturing, relative outsiders can not only launch a product, but implement a new production mindset into an established industry. The company is bringing comfort and customization to fashion footwear with sustainable, on-demand production based on 3D printing.

Read MoreFor Sustainable 3D Printed Architecture Think Renewable, Not Permanent

The design choices of today won’t be the trends of tomorrow. Aectual chooses to embrace changing tastes by making it easy to procure and recycle 3D printed architectural elements.

Read More