Solukon’s SPR-Pathfinder Software for Automatic Depowdering

Formnext: It is said the algorithm-based SPR-Pathfinder calculates the ideal motion sequence for the most complex geometries, finding the best path to enable the powder to flow out completely.

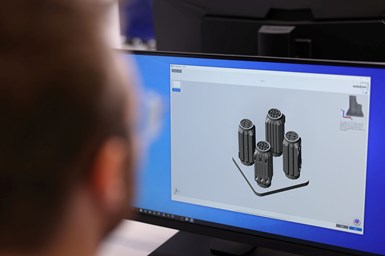

Solukon’s SPR-Pathfinder depowdering software enables automatic depowdering, making the digital twin of a part usable in postprocessing in the production process for the first time.

To remove excess powder from complex internal structures, SPR-Pathfinder uses the build job’s CAD file to calculate the ideal motion sequence in the Solukon system. The software calculations are based on a flow simulation that analyzes the part’s digital twin. The individually-calculated motion sequence is then read by the Solukon system, which in turn runs the programmed paths. This is said to ensure that even the most complex parts are cleaned — in record time and without any human programming effort.

“In contrast to conventional manufacturing processes, 3D printing uses the part’s digital twin. To date, however, this was only utilized during the printing itself,” says Andreas Hartmann, Solukon CEO/CTO. “ With SPR- Pathfinder, the part's digital twin can now also be used during depowdering. This is how we ensure that the potential of the digital twin can be used to the fullest in postprocessing as well.”

In 2018, the software developed by Siemens Technology in a joint project with Solukon was unveiled publicly for the first time under the name SiDAM. The software was the brainchild of Dr. Christoph Kiener, principal key expert on Functional Design for Manufacturing at Siemens Technology.

“Vibration-excited powder behaves almost like a fluid when it flows out. That’s how we quickly realized that we could find success by using path identification as well as particle and flow simulation in the software,” Kiener says. In 2019, Solukon and Siemens received the TCT Postprocessing Award for their use of the software in a Solukon SFM-AT800-S.

Until recently, the software prototype was only available to a select number of Siemens’ and Solukon’s development partners. Now, Solukon has acquired exclusive rights to the software, developed it into a Solukon product and is bringing it to the AM market under the new name, SPR-Pathfinder, enabling Solukon customers to purchase licenses for the first time.

“It's a logical step for us to license the depowdering software exclusively to Solukon, thereby enabling the pioneer in industrial depowdering to offer the market an even more effective product,” says Dr. Georg Bodammer, senior venture director at Siemens Technology Accelerator. “This way, customers can get everything from a single source: the market-leading depowdering system and the exclusive, intelligent software.”

In naming the software, Solukon deliberately drew on the established depowdering technology Smart Powder Recuperation, also known as SPR. The SPR generally involves automated rotation on two axes as well as adjustable vibration in a safety-controlled atmosphere. The algorithm-based SPR-Pathfinder calculates the ideal motion sequence for the most complex geometries, finding the best path to enable the powder to flow out completely.

- Learn how Launcher is utilizing a Solukon Depowdering System for postprocessing rocket parts.

- Watch this video with AM Executive Editor Stephanie Hendrixson talking about Solukon’s automated depowdering solutions at Formnext 2021.

- In this AM Radio podcast, AM Executive Editor Stephanie Hendrixson talks about the need for more automated ways to get parts from print to finish and how Solukon is helping with its postprocessing solutions.

Related Content

Solukon Upgrades SFM-AT350 Depowdering System for Medium-Sized Parts

Formnext 2023: System upgrades include the addition of the SPR-Pathfinder depowdering software, a new form of excitation for depowdering delicate structures and new tracking options with the enhanced Digital Factory Tool.

Read MorePostProcess, EOS Create Partnership for Automated Depowdering

The strategic partnership is designed to enable more sustainable automation through the additive manufacturing workflow.

Read MoreGrenzebach Develops Automated Depowdering System for SLM Solutions

The DPS NXG enables automated depowdering of 3D components up to 2.3 tons.

Read MoreDepowdering Station Automatically Cleans Unused Metal Powder from 3D Printed Build Jobs

The Volkmann additive manufacturing technology is designed to safeguard workers from toxic materials and boost efficiency.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)