Nano Dimension Broadens Range of Fabrica Micro-AM Printers

Formnext 2023: The key difference between the new Tera and Giga machines is essentially the build volume, with the smaller Giga machines designed for prototyping applications, while the larger Tera machines are aimed at higher volume production.

Share

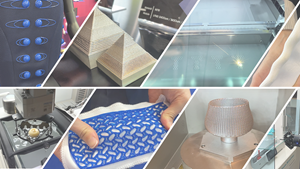

Nano Dimension’s additive manufacturing (AM) group has expanded its Fabrica Micro AM product line with a broader range of systems, including the Tera 25, Giga 250 and Giga 25, to offer new options for varying customer needs.

“Nano Dimension is responding to an exponential interest from industry, and our Fabrica range of Micro-AM solutions have been developed as compelling solutions for industries seeking precise and efficient micro manufacturing processes,” says Ziki Peled, president of Nano Dimension EMEA. “With the ability to create intricate structures and components on a micron scale, micro AM offers unparalleled design freedom and complexity, enabling the production of highly customized and optimized parts.”

The company says the micro technology minimizes material waste and reduces the need for assembly by fabricating complex geometries in a single build, leading to improved overall efficiency. “Industries such as electronics, medical devices, aerospace and automotive are finding immense value in Micro-AM, which is poised to play a pivotal role in driving innovation, cost-effectiveness and competitiveness across various sectors in today's rapidly evolving industrial landscape,” Peled adds. “Our suite of alternative micro AM solutions now allows us to meet the full range of strategic and application-specific customer requirements.”

The key difference between the Tera and Giga machines is essentially the build volume, with the smaller Giga machines aimed at prototyping applications, while the larger Tera machines are aimed at higher volume production. Both the Tera 250 and the Tera 25 have a build volume of 50 × 50 × 100 mm, while the Giga 250 has a build volume of 6 × 9 × 45 mm and the Giga 25 a build volume of 12 × 18 × 45 mm.

Both the Tera and Giga machines are capable of micron-level resolution. However, for companies looking to initiate prototype builds, the highly exacting resolution, tolerance attainment and surface roughness capabilities of the Tera series are not necessary. Unlike conventional prototyping, Micro-AM enables the direct creation of intricate and complex geometries without the constraints of subtractive manufacturing processes. This not only expedites the design iteration process but also enables the production of prototypes that accurately represent the final product's intended form and function.

“We have developed the Giga series of machines so our customers can cost-effectively benefit from micro-AM’s transformative approach to precision part and component prototyping, which surpass traditional methods in several crucial aspects,” Peled adds. “Micro-AMs high precision and fine resolution capabilities ensure the replication of intricate details and features, resulting in prototypes that closely mimic the end product’s characteristics. By embracing Micro-AM, industries can significantly accelerate innovation, reduce development lead times, and achieve a higher level of confidence in the functionality and performance of their prototypes.”

The Giga 25 and Tera 25 machines exhibit optical resolution of 8 microns, tolerance accuracy of 5 microns and achieve 0.9 micron surface roughness (Ra). The Giga 250 and Tera 250 exhibit optical resolution of 2 microns, tolerance accuracy of 2 microns, and achieve 0.4 micro surface roughness (Ra).

The range of build volumes, optical resolution, tolerance and surface roughness capabilities offered through the Giga and Tera machines are designed to fulfill a full range of customer prototyping and production requirements.

“Our mission is to democratize the use of Micro-AM in all industry sectors and application areas that can benefit from the use of 3D printing,” Peled says. “The economics and timeliness of Micro-AM as a prototyping technology are compelling. In the realm of production, Micro-AM's capacity to manufacture miniaturized yet functional components with remarkable precision is reshaping industries, from electronics to health care, by enhancing product performance, reducing assembly complexity and unlocking new realms of innovation.”

- Read about the Nano Dimension acquisition of Admatec and Formatec. With this acquistion, Nano Dimension says it is adding two critical aspects to its offering in the AM domain — materials and new product types.

- Learn how the Nano Dimension 3D printer complements micro moldmaking capabilities, providing a way for micro mold provider Accumold to produce microscale prototypes and rapid tooling.

Related Content

10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

Formnext Forum: Austin, a two-day event at the end of August focused on additive manufacturing for production, includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Read MoreFinland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)