Stoke Space Uses Solukon Technology for Depowdering of Rocket Parts

Stoke’s first- and second-stage engine thrust chambers are additively designed and manufactured in-house with regenerative cooling channels and built-in manifolds, which have features and internal cavities that are typically difficult to depowder.

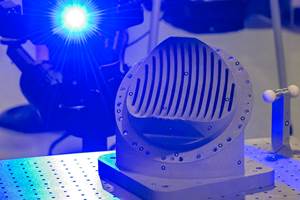

Stoke Space is utilizing Solukon’s SFM-AT800-S SPR depowdering technology for the copper thrust chambers it designs and produces using additive manufacturing (AM). The company says the copper thrust chambers for its rapidly reusable rockets present an exceptional depowdering challenge.

The U.S. space launch company is located in Kent, Washington, where it builds what it calls the world’s most efficient fully and rapidly reusable rocket designed to fly daily. It is said that Stoke’s rocket can radically increase access to space, opening the space economy for new and innovative technologies on orbit.

Thrust Chambers With Complex Inner Structures

Both of Stoke’s first and second stages are fully reusable. The second stage, usually thrown away in the conventional space industry, is able to reenter Earth’s atmosphere and land after deploying payloads in space.

To enable rapidly reusable vehicles, both of Stoke’s first- and second-stage engine thrust chambers are additively designed and manufactured in-house. These thrust chambers feature regenerative cooling channels and built-in manifolds, which has features and internal cavities that are typically difficult to depowder. This is why Stoke Space is relying on Solukon’s depowdering technology in the SFM-AT800-S.

The SFM-AT800-S is Solukon’s flagship machine for tough depowdering challenges and the company says it is the most widely used automated powder removal system in the AM industry. The SFM-AT800-S can handle metal parts with maximum dimensions of 600 × 600 × 600 mm (or alternatively 800 × 400 × 550) weighing up to 300 kg. Based on the Solukon Smart Powder Recuperation technology SPR, the SFM-AT800-S uses targeted vibration and unlimited 2-axis rotation in a protected atmosphere to get unfused powder out of metal laser melted parts fully automatically.

Stoke additively prints its thrust chambers using a special copper alloy with a high conductivity to enable maximum reusability. However, copper powder makes complete powder removal more challenging due to its tendency to stick and clump within the tight regenerative cooling channels. Stoke uses a high-frequency knocker provided as an add-on in the Solukon system to loosen trapped copper powder bulks from internal channels of the parts. Stoke also applies an ultrasonic vibration system to enhance the flow of the copper powder, which is directly connected to the component.

For complex geometries there’s another way to optimize depowdering even further — by analyzing the part’s CAD file. The Solukon depowdering software SPR-Pathfinder works with a digital twin of the part and calculates the motion pattern for the Solukon system automatically to get the powder out of the complex structures. “SPR-Pathfinder is a convenient tool to optimize the depowdering before it even started,” says Andreas Hartmann, Solukon CEO and CTO.

Solukon technology plays an important role in Stoke Space’s strategy to harness the power of 100% reusable rockets to unlock affordable access to, through and from space. “We chose Solukon for their industry-leading capability in automating depowdering of complex parts,” says Zach Sander, head of Engine and Fluid Systems at Stoke Space. “Regeneratively cooled rocket engine thrust chambers are notoriously difficult to depowder, and we wanted to ensure we had a robust machine to reliably depowder these difficult copper components.”

Related Content

Additive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreSidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

Read MoreEOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreRead Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More

.jpg;maxWidth=300;quality=90)