America Makes Announces Project Call for Process Qualification/Requalification Totaling $3.2M

Proposal submissions for the Demonstration of Novel Methods for Effective AM Process Qualification/Requalification – Delta Qualification project call are due by May 22.

The National Center for Defense of Manufacturing and Machining (NCDMM) and America Makes have a new directed project call funded by the Air Force Research Laboratory (AFRL) worth a total of $3.2 million.

The objective of the “Demonstration of Novel Methods for Effective Additive Manufacturing (AM) Process Qualification/Requalification – Delta Qualification (Delta Qual)” project call is to establish a qualified AM process, rapidly and affordably, enabling changes in key AM process, postprocessing and/or material feedstock variables while efficiently validating a qualified AM material through statistical analysis.

To be eligible for an award, the lead proposer must be a current member of America Makes. The submission deadline is Monday, May 22, 2023, with an anticipated awards announcement on Friday, June 23, 2023.

The group says qualification of AM machines and materials is a major barrier to a broader adoption of AM. Generating the requisite data and models requires substantial resources to produce statistically significant data and perform testing and analysis of the resulting data. It is said this greatly inhibits the agility of the AM processes to respond to changes in the technology or the supply chain base, requiring a total requalification that can be extremely costly and time-consuming.

The proposed projects should be applicable to Technology Readiness Level (TRL) 4-7 and Manufacturing Readiness Level (MRL) 4-7 at the onset of the proposed project. NCDMM and AFRL anticipate funding up to seven awards in three major areas of Delta Qual, however, the combination and number of awards per topic are not fixed.

Topic 1: Major Delta Qualification Demonstration (up to two awards, not to exceed $700,000). Topic 2: Minor Delta Qualification Demonstration (up to four awards, not to exceed $350,000). Responses to Topics 1 and 2 should seek to make a single change to the baseline process and employ advanced numerical, analytical and experimental methodologies to accelerate and reduce the cost of establishing equivalence to the baseline. The goal is to achieve at least a minimum of equivalence to the performance of the baseline material. Responses to both topics are limited to Ti-6Al- 4V grade 5 powder bed fusion.

Topic 3: The Red Team (one award anticipated, not to exceed $400,000). Responses to Topic 3 should outline an approach that includes a metal AM process-specific team to serve as subject matter experts to collect and harmonize AM standards and provide a map as to how standard organizations can include useful language for updating AM Process Qualification.

“This project call is designed to provide America Makes and our stakeholders with a framework of qualification methods and data points that enable new technologies, solutions and processing standards to be rapidly qualified for use within the nation’s additive manufacturing supply chain,” says Brandon Ribic, America Makes technology director. “To remain competitive, the AM industry must quickly adapt to the needs of the warfighter and other commercial users that are often confronted with excessive costs and years to qualify minor changes in their AM processes. Delta Qual is a very important step to provide foundational information for the industrialization of AM technologies.”

- Read about America Makes’ 2022 Project Awards for proposals that address evolving challenges of the domestic supply chain and offer progressive solutions.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreHow Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

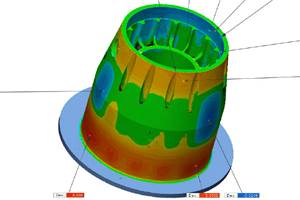

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)