The Power of the Particle: Characteristics That Affect Powder Bed Fusion AM

A recent webinar explores the influence of powder properties and the direct effect they have on AM build outcomes. Detailed are several methods for measuring characteristics of particle shape, size and surface chemistry during the feedstock life cycle.

The influence of particle size and shape is pivotal in understanding the process of powder bed fusion (PBF). Additive manufacturing via PBF, in metal or polymer, whether by laser powder bed fusion, electron beam melting or selective laser sintering, offers a heightened level of detail complexity relative to other AM processes in combination with a wide range of materials suitable for differing demands. But in all these processes, the characteristics of the powder feedstock — particle shape, size and surface chemistry — directly impact the outcome of the AM build. They affect various aspects of the process, such as powder bed formation, powder spreading and melt characteristics. In a recent webinar, Malvern Panalytical scientist Paul Carpinone, Ph.D., described the impact of powder properties in PBF and several ways to measure them during the feedstock lifecycle.

Size and Distribution

“A balance of multiple factors determines powder flowability, spreadability and performance,” says Dr. Carpinone, noting that opposing effects are hard at work behind the scenes of powder bed fusion. For instance, take the favorable relationship between flowability and spreadability. Both of these improve in tandem when a coarser particle is selected for feedstock. However, “Layer resolution, uniformity and final part surface roughness tend to favor finer particles,” says Dr. Carpinone. Differing outcome demands require the optimization of particle size to realize the product and process required.

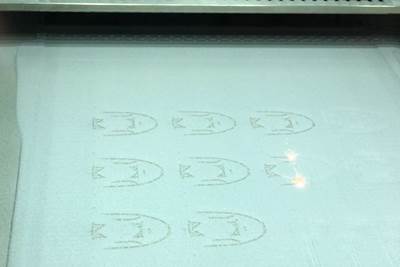

As depicted on the far left, the grouping of particles with the smallest mean diameter results in the most uniform build layer. Photo Credit: Malvern Panalytical

Geometric Considerations

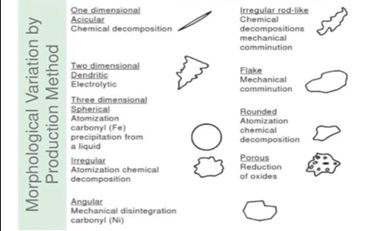

Chart offers the variations of morphological types found in powder bed fusion. Photo Credit: Malvern Panalytical

Following size comes the importance of shape. The variety of AM powders available on the market allows for choosiness. However, material that provides flowability is optimal. Smooth and spherical powder shapes are preferred, Dr. Carpinone says. This is because angular or irregular shaped particles will result in unwanted friction between particles.

Shape is a result of powder production method. Atomization is one method used to attain the spherical particle shape PBF favors. Morphological types — some pictured in the above image on the right — each offers a unique set of characteristics to consider in the PBF process.

Surface Chemistry

Dr. Carpinone says that with increased powder surface area comes the likelihood of a surface reaction (such as oxidation), resulting in moisture adsorption (a different concept than absorption). A common concern in AM, water adsorption negatively impacts flowability of the powder and the functionality of the product. When powders are exposed to certain amounts of humidity, there are varying results. The correct amount of dehydration of the powder will result in a targeted flowability, he says.

“There is a synergistic effect between the fine particle size, which would provide higher surface area for these adsorption characteristics and the fact that the surface interactions [interparticle interaction forces] which tend to be cohesive also increase substantially as we increase in particle size,” says Dr. Carpinone.

This further demonstrates why balance is vital in selecting powder characteristics. Considering the various powder factors that are essentially competing within the powder bed fusion process, how can these factors be measured to ensure optimization?

The Measurement Toolbox

Dr. Carpinone discusses helpful tools for measuring particle characteristics. Below are descriptions of each method he discussed in the webinar.

- Laser diffraction is primarily used to evaluate the micromaterial of powder feedstock to generate a quick particle size distribution result. Conveniently, powders can be in a wet or dry state for this handy technique.

- Dynamic light Scattering evaluates nanomaterial particle size distribution as well as the dispersion stability of the powder.

- Static and dynamic imaging systems measure both particle size and shape. These systems boast usefulness in determining feedstock flowability, packing and spreadability evaluation.

- Process laser diffraction is an instrument that primarily focuses on particle size analysis in the powder production. This method offers real-time process studies, resulting in faster optimization. This method can also be used for hazardous applications such as the production of aluminum powder.

These instruments can be incorporated into almost any point within the AM feedstock lifecycle, to help ensure powder remains a consistent and (ahem) well-rounded product.

Related Content

What is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

What is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreVideo: What Is Laser Powder Bed Fusion (LPBF)?

Laser powder bed fusion is likely the most widely used metal additive manufacturing process. Here is how it works, including benefits, issues to consider and applications for this 3D printing technology.

Read More25 Years Later, What’s Exciting in Electron Beam Powder Bed Fusion?

Often seen as runner-up to laser powder bed fusion, are we finally in the golden age of the electron beam?

Read More

.png;maxWidth=300;quality=90)