3D printing is perhaps the production technique best positioned to take advantage of the promise of Industry 4.0. Most of the information needed to produce a part this way (design file, slicing, printer parameters) is already in a digital format, the prerequisite for tracking, analyzing and optimizing manufacturing data. Yet just because the information is available does not mean it is connected or that the various systems involved can speak to one another in any meaningful way. When 3D printing is for prototyping, disparate pieces of information spread across the enterprise pose less of a challenge — but as the technology moves toward production via additive manufacturing (AM), it becomes increasingly important to bring these various sources of information into conversation with each other.

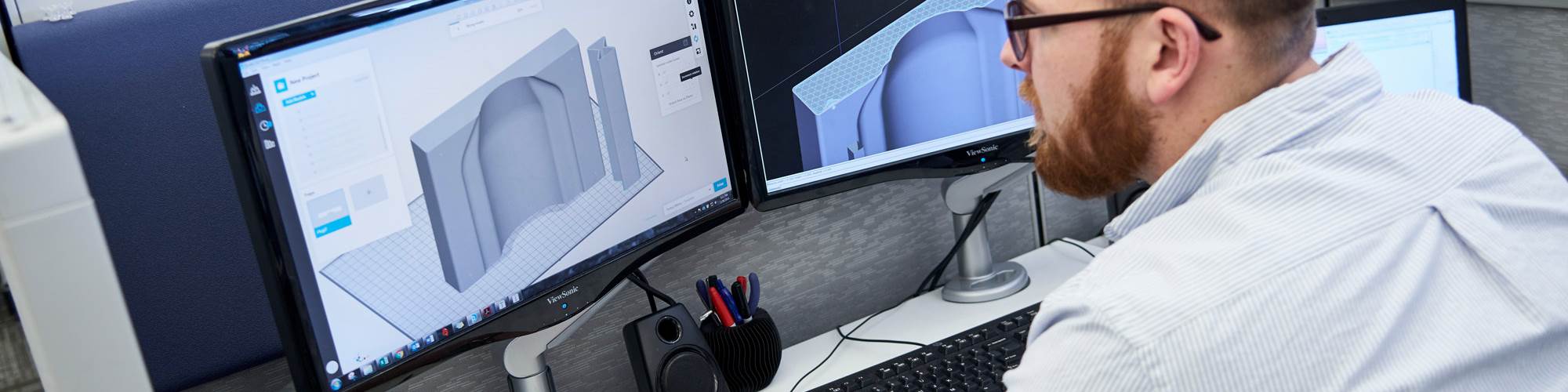

The shift toward production is one driving factor behind Stratasys’s recent introduction of the GrabCAD Additive Manufacturing Platform. In a virtual press conference held October 28, representatives from Stratasys and its partners emphasized the need for interoperability across design, job planning, 3D printer operation, postprocessing, order fulfillment and more. This new platform offering is a way for manufacturers to connect these pieces of their business, either in the cloud or captively on site.

Nadav Goshen, Stratasys executive vice president of software, summarized the three key attributes of the GrabCAD Additive Manufacturing Platform:

- It enables connectivity such that “machines and files and data are connected together,” he says. Manufacturers can maintain traceability from design through delivery, critical in a production environment, and use the data to optimize processes as well as parts and printers.

- It is open. Stratasys recognizes that manufacturers commonly use 3D printers and equipment from various builders, and has made the platform open to integration with any combination of hardware and software. GrabCAD Software Development Kits (SDKs) make it possible for any developer to develop workflows and applications on top of the platform. More than a dozen Software Partners have been added in 2021, including AMFG, Link3D, Siemens and Teton Simulation.

- The solution is enterprise-ready, meaning it is intended for manufacturers using additive manufacturing for scale production (and thus supports security measures and flexibility that these enterprise users need). In addition to use by companies already engaged in AM production, the platform can be a tool to “enable customers to amplify business transformation by scaling 3D printing into additive manufacturing,” Goshen says.

The platform builds on and integrates GrabCAD Print, which launched in 2016 to support the programming and planning of 3D printed parts, as well as GrabCAD Shop for part and order management, introduced in 2020. A cloud-based asset management software-as-a-service (SaaS) solution called GrabCAD Print Manager will be added in 2022. The platform components can be used individually or in combination through licensing and SaaS agreements.

Related Content

-

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

-

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

-

New Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)