Micro 3D Printing Slashes Costs, Lead Time for Medical Part

Micro 3D printing enabled AntiShock to produce a small-dimension, high-detail part with greater accuracy than SLA and at 20% of the cost of CNC production.

Dmitri Khalilov, cofounder and CTO at AntiShock Labs.

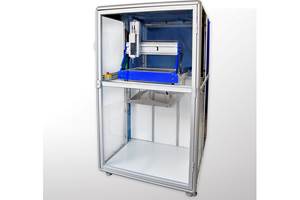

Photo Credit: 3D Evaluate

AntiShock is a medical device start-up company whose headlining product is a disposable, non-invasive, continuous monitoring system that measures patients’ systemic fluid responsiveness to prevent intravenous fluid (IV) overload. Fluid overload is a common condition among intensive care unit (ICU) patients that can cause organ failure and, in severe cases, death.

To further improve its solutions to this problem, AntiShock is developing an electro-optical sensing medical device based on a tiny electro-optical sensor. This sensing device is built out of several small mechanical moving components with high strength and accuracy requirements. Therefore, to validate its product and produce a working prototype device, AntiShock turned to advanced manufacturing technologies.

AntiShock initially considered CNC machining and the stereolithography (SLA) 3D printing process that created the first product mock-up. However, when confronted with the need to produce a small-dimension, high-detail component about 1 mm in diameter, available SLA technology could not provide the required levels of details and accuracy. CNC machining could produce these parts, but the resulting per-part cost was expensive.

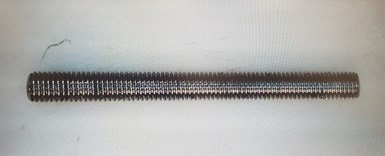

The threaded screw inside AntiShock’s medical device. Photo Credit: AntiShock

Micro 3D Printing

While searching for a solution to this problem, Dmitri Khalilov, co-founder and CTO of AntiShock, came across Nanofabrica’s micro 3D printing system. Curious and intrigued, Khalilov made contact with Avi Cohen, Nanofabrica’s executive vice president of sales, presenting the challenge of producing AntiShock’s small-dimension, high-detail component.

The challenge went beyond printing the component: the part needed a non-standard-pitch thread that could fit a small screw on top of it, the components had to fit each other perfectly, and the final component had to be strong enough to sustain mechanical loads.

After reviewing the part’s size, geometry and thickness, and estimating the mechanical loads the part needed to withstand, Nanofabrica accepted the challenge. Only a few days after delivering a CAD file, the AntiShock R&D received a complete, 3D printed prototype. The team swiftly moved to evaluate the part’s accuracy and verify the production of the required details. The part passed with flying colors — and fit the small metal screw.

The micro 3D printed part for AntiShock’s medical device fit perfectly onto the small metal screw. Photo Credit: AntiShock

The Benefits of Micro 3D Printing

After reviewing the data, AntiShock concluded micro 3D printing offered distinct advantages in various areas.

First, micro 3D printing had the ability to provide the challenging levels of detail and accuracy required, even at resolutions too small for traditional 3D printing. Micro 3D printing also promotes design freedom, and so facilitated the production of AntiShock’s part without many of the design limitations baked-in with conventional production processes. The delivery time for five 3D printed parts was one day, whereas delivery times with CNC would have been between three to four days. Micro 3D printing also saved 80% on costs compared to CNC’s several hundreds of dollars.

Final Conclusions

Less than a week after beginning work with Nanofabrica’s micro 3D technology, AntiShock’s team solved their problem. The possibility of micro 3D printing opened up a wide range of R&D possibilities for AntiShock regarding its existing and future devices. Micro 3D printing also integrated well with AntiShock’s existing to CNC and SLA 3D printing workflow, as these other production methods produced device’s larger parts.

Related Content

Chromatic RX-Flow 3D Printers for Reactive Extrusion Additive

RX-Flow printers are a low-cost option for manufacturers interested in testing and implementing industrial 3D printing with more durable, flexible materials than are available with FDM, SLA and other 3D printing technologies.

Read More3D Systems’ Accura AMX Resin Withstands Harsh Thermal Environments

Formnext 2023: The resin material is well suited for the testing of high-temperature components in applications such as HVAC, consumer appliances, motor enclosures, fixtures, mounts, stators, molding/tooling and more.

Read MoreEvonik Adds Three Infinam Photopolymers to Product Portfolio

Formnext 2022: These photoresin products are for use in common UV-curing 3D printing processes such as stereolithography (SLA) or Digital Light Processing (DLP).

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More

.png;maxWidth=300;quality=90)