ParaMatters’ CogniCAD 4.0 Delivers Smooth, Automated Workflow

Design platform enables both digital and traditional manufacturers to automate design-to-manufacturing processes.

Share

CogniCAD 4.0 delivers smooth, automated workflow.

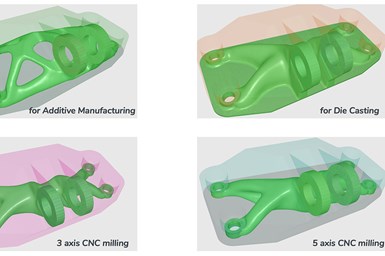

ParaMatters’ CogniCAD 4.0 software upgrade delivers a smooth, automated workflow from design to manufacturing for both digital and traditional manufacturers. The software automatically generates ready-to-manufacture, high-performance, lightweighted structures for aerospace, automotive and other mission-critical applications.

The company says that CogniCAD 4.0 gives engineers and designers the flexibility to generate effective designs using a wide range of manufacturing options, including the use of additive manufacturing (AM), 3-axis and 5-axis CNC milling, and investment and die casting. Version 4.0 provides more robust and faster solvers which enhance vibration and stress constraints design with more control over geometry and manufacturing, like multiplane symmetry constraints and accurate feature size. It offers a new advanced support structures generator to help designers and engineers prepare files for 3D printing, and optimal part orientation, fast slicing and hollowing for investment casting with new features for latticing and gyroids to enable greater efficiency while saving on materials for prototyping.

CogniCAD 4.0 works by first importing CAD files into the platform and then defining loading, design and manufacturing criteria. Within tens of minutes, users can obtain generative designs verified by built-in, finite-element analysis, ready for 3D printing in both STL/PLY and STEP formats. All ParaMatters-generated designs can be directly produced using AM and can also be transferred to traditional manufacturing processes.

Related Content

-

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.