Intrepid Automation’s Valkyrie Systems for Industrial-Scale Additive Manufacturing

System features modular DLP technology for a customizable, industrial-scale system for high-volume production.

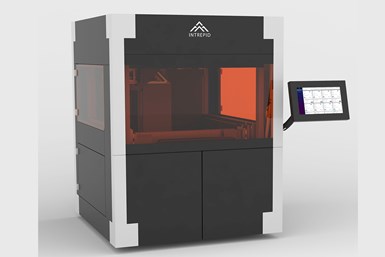

The Valkyrie system has customer-validated print speeds of up to 44 mm/hour using IntrepidCast LF resins. Photo Credit: Business Wire

Intrepid Automation’s Valkyrie 3D printing system is a large-format, industrial-grade, modular tool for manufacturing customers to quickly scale production of printed patterns, molds and parts. The system features a build area of 660 × 760 × 560 mm and has customer-validated print speeds of up to 44 mm/hour using IntrepidCast LF resins, which is said to enable users to produce end-use parts up to 10 times faster than legacy SLA processes.

Valkyrie systems run on Intrepid’s moduclar DLP technology, which is a process that uses an array of highly calibrated digital light sources to project a single, high-accuracy image at once, rather than tracing image outlines as it is with legacy SLA processes.

As part of close partnerships with multiple industrial-scale resin suppliers, the company has been able to develop and validate custom materials for applications in both investment casting patterns (IntrepidCast LF resin family) and rigid part/mold production (Intrepid ThermoRigid resin family) on Valkyrie systems.

Automatic calibration and proprietary software are said to ensure print-to-print and printer-to-printer consistency as customers scale manufacturing. The modular system is designed to scale with production needs. The system is also customizable for use with application-specific resins/print materials.

Related Content

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

-

How Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

.png;maxWidth=300;quality=90)