Arburg Develops High-Temperature Version of Freeformer 750-3X for Polymer 3D Printing

The machine is well suited for the manufacture of geometrically intricate polymer parts that require high-temperature production.

Share

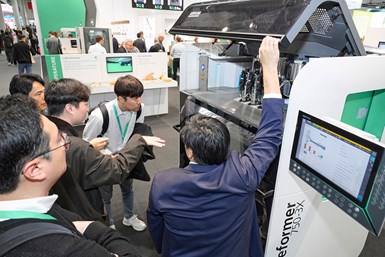

A high-temperature version of the new Freeformer 750-3X can additively manufacture ventilation ducts for the aerospace industry from Ultem 9085 original plastic granules. Photo Credit: Arburg

Arburg has developed a high-temperature version of its Freeformer 750-3X which can process Ultem 9085 original plastic granules. The build chamber can be tempered to 200°C, with plastification of the plastic granules taking place at up to 450°C. In comparison, the maximum temperature of the build chamber in the standard Freeformer 750-3x is 120°C.

The machine is well suited for the manufacture of geometrically intricate parts such as air distributors (ventilation ducts) for aerospace manufactured from original Ultem 9085 granulate. Ultem is just one example of a 3D printed polymer that requires high-temperature production.

The Freeformer 750-3X 3D is designed as an open system utilizing the Arburg Plastic Freeforming (APF) process for custom-configured additve manufacturing (AM). The system is said to meet individual user requirements by adjusting slicing, droplet size and process regulation to influence the layer-by-layer build process utilizing a broad range of materials.

The APF process is a unique AM material jetting method. In APF, a thermoplastic material is supplied as pellets, melted and selectively deposited as droplets, enabling the use of commercial materials in their original shape instead of filaments.

The 750-3X features a large build chamber which is approximately 2.5 times larger than that of the Freeformer 300-3X. It is well suited for the rapid series production of large components or several articles per construction order. Its printing and space configuration are optimized. The principle of material preparation remains the same in the Freeformer 750-3X, but the entire system — preparation and discharge units — has been optimized so the unit could be designed more compactly. From a strictly external point of view, the machine cannot be distinguished from the 300-3X, as it has the same external dimensions. However, the part carrier is around 2.5 times larger at around 750 m3.

The larger build chamber measures 330 × 230 × 230 mm. The temperatures are kept stable without any special air flow or circulation as a result of several technical innovations. These include melt pressure generators for dosing and injecting, which use servo motors from AMKmotion (an Arburg company). This enables the three discharge units to be positioned more closely to each other and in a more compact way. Due to advanced software features of the control system, it is possible to increase the printing speed considerably. For example, process-optimized latticed support structures can be created where the build time is up to 55% faster than with conventionally constructed ones, the company says.

- Learn more about Arburg’s Freeformer printers, including the 750-3X 3D which features a larger build chamber. The Freeformer 750-3X 3D provides more space inside the build chamber for larger components.

- Read about Arburg’s Compact TiQ 5 Pro which offers versatile 3D printing for fiber-reinforced filaments. The TiQ 2 is particularly economical and well suited as an entry-level additive manufacturing solution because of its open material system.

Related Content

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)