Acrotec, AddUp Partner for the Future of the Medtech Sector

Acrotec and AddUp are combining expertise to enable the development of additive and industrial solutions dedicated to the medical sector, which is constantly evolving and looking for more innovative tools.

AddUp has worked in close collaboration with customers in the Medtech industry to develop and manufacture a wide variety of implants and instruments for surgeons and health professionals.

The partnership between Acrotec and AddUp plans to enable the development of additive and industrial solutions dedicated to the medical sector, which is constantly evolving and looking for more innovative tools. These high-precision tools meet strict manufacturing standards that AddUp’s customers, which have been active in the medical field for several years, have mastered.

“Players in the medical field have understood all the benefits of metal 3D printing and many implants or instruments are already manufactured using this technology,” says Julien Marcilly, AddUp deputy CEO. “As a supplier of metal 3D printers and parts, AddUp chose to partner with an experienced and recognized innovative partner, Acrotec. With Acrotec’s knowledge of the Medtech industry and expertise in precision machining and AddUp’s mastery of the metal 3D printing process, our partnership will offer the best solutions for customers in this demanding market.”

The Acrotec Group, through its Medtech division, is focused in the spine, traumatology and dental sectors. Acrotec Medtech produces implants and instruments to be used for surgical procedures. Over the years, the group has honed the necessary skills to manufacture precision components and subassemblies for medical devices, specifically in the machining and finishing of metal parts. This experience has made Acrotec Medtech a known industrial partner for the production of spinal and dental implants, as well as many instruments used in surgical procedures.

The use of additive manufacturing (AM) in the health care industry is increasing thanks to a reduction in cost when compared to traditional manufacturing and an improved design with options for personalization. AM technology also offers the opportunity to create personalized devices for patients to help transform health care as we know it today.

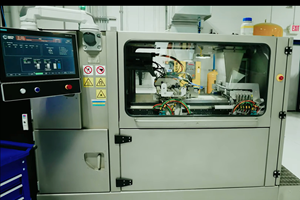

Among the materials available on its FormUp 350 machines, AddUp also offers recipes for shaping extra low interstitial (ELI) titanium. This grade of titanium is most commonly used by most manufacturers of surgical implants and prostheses. In addition to its biocompatibility, ELI titanium is nonmagnetic and has very high mechanical characteristics.

AM enables the creation and production of parts with complex and organic geometries, which would be impossible or very costly to produce using traditional CNC manufacturing technology. Production of these types of geometries using AM is also faster and more flexible, which provides an increase in productivity for medical device manufacturers.

“With AddUp as a partner, we are trying to push metal 3D printing technology to its limits in terms of part sizes and associated material health. The quality of AddUp’s printing systems as well as the expertise and motivation of the teams have allowed us to move forward in an open and efficient way in this initiative,” says François Billig, Acrotec Group CEO. “We are confident that through our partnership, Acrotec can now develop and utilize this technology with its customers in the Medtech sector.”

- Learn about AddUp’s partnership with Research Institute of Sweden (RISE) and the steps being taken to accelerate AM adoption in Sweden.

- Read about the opening of AddUp’s North American HQ which is a a proving ground for Metal AM, showcasing its laser powder bed fusion and directed energy deposition technologies.

Related Content

From Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreRead Next

GE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More

.png;maxWidth=300;quality=90)