The story isn't new—long lead times and extraordinarily high costs to cut tools during product development plagues injection molders. You order tools overseas to keep costs down, but now have to worry about supply chain issues on top of long lead times. However, cutting a metal tool domestically for low-volume and prototyping can eat up your whole product development budget.

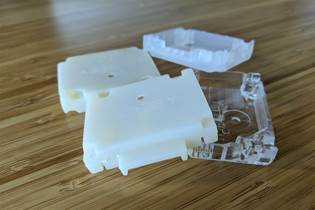

This webinar will showcase a solution with Fortify's 3D-printed injection mold tools that can mold parts with complex designs—even in high-performance plastics—in a matter of days. Hear from the applications engineering team at Fortify on how this process can lower costs and lead times. Fortify's contract manufacturing partner, Empire Group, will share real-life case studies of this technology being utilized in product development. Spoiler alert: a significant amount of time and money were saved in these examples. Lastly, Fortify will share how you can get started with a molding project.

Register for this webinar and learn how:

- You can mold parts in engineering-grade plastics with a 3D-printed mold tool

- You can resolve your supply chain issues for mold tooling

- You can get started on a low-cost, quick-turn project

Agenda:

- Overview of materials and types of parts that can be injection molded on Fortify's 3D-printed mold tools

- Lead time and product development example

- Real examples of customers using Fortify's 3D-printed mold tools for product development to lower lead times and cost

- Automated mold design for Fortify customers

.png;maxWidth=300;quality=90)