ExOne, Ford Motor Co. Develop Aluminum Binding Jetting Process

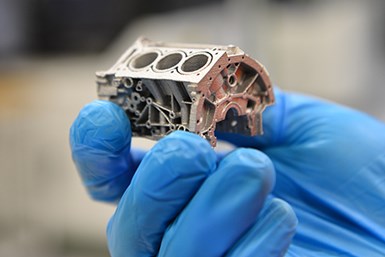

This aluminum engine block model, 3D printed in 6061, demonstrates the high resolution and geometric control that can be produced in a new binder jet 3D printing and sintering process developed by Ford and ExOne.

Share

This aluminum engine block model, 3D printed in 6061, demonstrates the high resolution and geometric control that can be produced in a new binder jet 3D printing and sintering process developed by Ford and ExOne.

In a project co-funded by Ford Motor Co. and the ExOne Co., a team of engineers, material scientists and manufacturing experts has developed a process for rapid and reliable binder jet 3D printing and sintering of aluminum that delivers properties comparable to die casting.

The process was developed for binder jetting aluminum 6061, one of the most commonly used aluminum alloys in the world, delivering final parts with 99% density and material properties comparable to traditional manufacturing.

This process for future production of aluminum parts is much faster than other 3D printing methods and capable of scaling to the volumes needed for automotive use, the company says. The process is expected to increase Ford’s efficiency by enabling the company to affordably produce complex parts uniquely designed for additive manufacturing, which enables size and weight reductions, part consolidation and performance improvements.

The innovation came about through the process of binder jetting, widely regarded as the fastest method of metal 3D printing for high-volume output. It uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. The heating process reinforces the strength and integrity of the metal, and while the process for sintering stainless steel is well understood, achieving high densities greater than 99% is an industry breakthrough for aluminum, the company says.

The Ford-ExOne joint development project was first initiated in 2019. Ford has led the final material and repeatability testing to verify its accuracy. The cross-functional Ford-ExOne team is actively working on designs to use the new material and process.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Multimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

-

Sintratec Adds More Power in S3 Selective Laser Sintering System

Formnext 2022: The system comes with a 30-W fiber laser, which is three times more powerful than the Sintratec S2, resulting in shorter printing times.