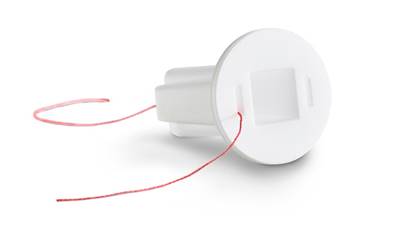

3D printed ceramics can supply a replacement for bone graft and support structures. This proof-of-concept example from Lithoz actually combines both, with a bioresorbable bone scaffold inside and a stiff outer cage for stability.

When bone graft is needed for a reconstructive surgery, the current gold standard is to take bone tissue from a patient’s own body. This autogenous graft has a good chance of successfully replacing the bone damaged by trauma or illness and leading to a full recovery. Yet most patients who have experienced this procedure say they wouldn’t do it again.

Why not? Bone graft harvesting is invasive and requires a large area for extraction — in most cases, graft is taken from the hip or the fibula. The bone tissue is typically gathered in a separate procedure, which means twice the surgeries, increased pain for the patient and doubled risk of complications. Additionally, the main surgery can be a long one because of the necessity of packing and shaping the graft by hand. Even a successful bone graft procedure is not a comfortable or easy one from the patient’s perspective.

Alternatives to autogenous bone graft include cadaver and bovine sources, but perhaps the most promising option is artificial bone. Bioceramics such as tricalcium phosphate (TCP) are gaining ground, and developments in the 3D printing of these materials are pointing the way toward future implants that can be customized to each individual’s anatomy while eliminating secondary surgeries, reducing the time spent in the operating room and leading to a better patient experience.

How to 3D Print Ceramics

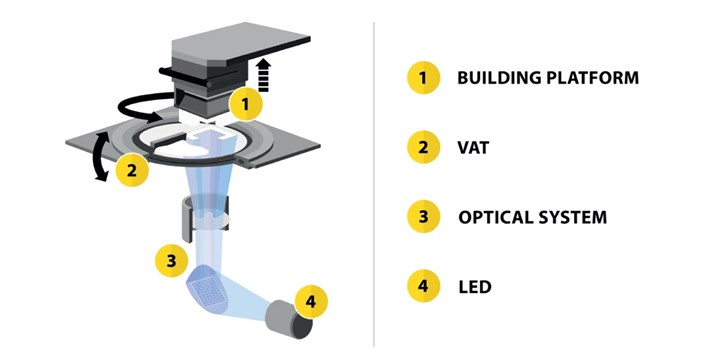

One company currently exploring the realm of 3D printed artificial bone is Lithoz, a developer of 3D printers and materials based in Austria. The company’s Lithography-based Ceramic Manufacturing (LCM) technology and CeraFab 3D printer have been applied to a range of ceramics including TCP but also magnesia, porcelain and zirconia (more on that in a moment).

Lithoz’s CeraFab 3D printers build up parts from a slurry of powdered ceramics and photopolymer resin. The Lithography-based Ceramic Manufacturing process cures the resin with projected light to produce a green part; the polymer is later burned out with a sintering process. Image: Lithoz

The LCM process is a digital light processing (DLP) 3D printing technique that uses light to selectively cure a slurry of polymer resin filled with a secondary, powdered material into an initial green part.

“The green body is a composite consisting of the polymerized photoresin with interspersed ceramic particles,” explains Daniel Bomze, head of the medical business unit at Lithoz. After the green part is cleaned of excess slurry, it is placed into a furnace to burn away the photoresin binder and achieve its final ceramic part properties. “The sintering process ensures that we will end up with the classic ceramic properties — for example, high hardness, high strength and wear, and smooth surfaces,” Bomze says.

But for bone graft replacement, a material like TCP serves a somewhat different purpose; rather than strength and hardness, the material’s advantage is biocompatibility and resorbability. TCP resembles the inorganic content of natural bone and can be used as a temporary solution to facilitate the regeneration of the patient’s own bone tissue. As this regeneration happens, the TCP implant will eventually dissolve away into the patient’s body to complete the healing process.

This bone scaffold made from tricalcium phosphate illustrates one advantage of 3D printing: the ability to create scaffold-like structures that encourage bone in-growth. Because TCP is resorbable, an implant like this would be temporary and slowly replaced by the patient’s own bone tissue. Photo: Lithoz

Powdered TCP is used in conventional surgeries, where it is mixed into a paste with the patient’s own blood and applied to the injured area by hand. But the ability to 3D print the material into a solid form provides new benefits. The implant can be made to exactly the right size and shape needed based on 3D data from a CT scan or MRI; this means less handwork for the surgeon and reduced time in the operating room. 3D printing also enables the incorporation of design features to facilitate and encourage bone in-growth, such as lattices and surface roughness that provide anchors for the native bone. Although TCP lattice structures are not meant to be durable over the long term, they can provide enough stability to allow delicate regions of the body such as cheek bones or eye sockets to heal on their own.

Replacing Both Cancellous and Cortical Bone

But 3D printing a bone graft replacement solves only part of the problem for many surgeries. Human bone is composed of both cortical tissue that forms a hard exterior and the sponge-like cancellous bone in the interior. TCP is a replacement for the cancellous bone only; for areas such as a jaw, it is also necessary to replace or augment the cortical bone.

Historically this has meant the uses of implants made from materials like titanium and PEEK that provide stiffness and strength. But 3D printed ceramics now offer another solution, one that can be used in conjunction with artificial printed bone replacement.

Lithoz researchers have developed a proof-of-concept solution for jawbone reconstruction, a mandibular cage implant that combines the resorbable TCP bone graft replacement and a rigid outer cage made from a different bioceramic: zirconia. The hybrid solution is made in three parts, the zirconia cage and two TCP inserts that can be inserted into the cage’s geometry. The resulting implant would provide both the stability and bone ingrowth needed to help a patient’s jaw heal. The zirconia cage can remain in place permanently while the TCP interior dissolves over time.

The jaw implant example is a dual-material implant that combines a zirconia cage for stability plus tricalcium phosphate bone graft inserts. The different materials are printed separately and then assembled together. Photo: Lithoz

“By combining a very high strength, very rigid material to give proper stability during the healing phase, in this case the zirconia cage, and a bioresorbable material that helps the body to form new healthy bone, in this case, tricalcium phosphate, we combine solutions from the best of two worlds,” Bomze says.

(Why not print the assembly complete? The sintering process is different for both feedstocks, and it would be more difficult to guarantee quality if they were to be sintered together, Bomze says. The shrinkage of the green ceramic part in sintering can be between 25 and 30%, and is dependent on each material. For now, the best results can be achieved by building the two portions individually and combining them.)

Customized 3D Printed Ceramic Implants

No patients have yet been treated with Lithoz’s dual-material implant. However, both TCP and zirconia are already safely used for other kinds of implants, and there is at least one ongoing study using 3D printed TCP implants alone in nonload-bearing scenarios that has so far been successful.

But the real promise of LCM and dual-material implants is the ability to customize them to the patient’s own anatomy. Down the road, Lithoz hopes to equip medical manufacturers and the surgeons they work with to be able to build exactly the zirconia cage needed and precisely the TCP lattice that will fit inside, using CT scan or MRI data.

(Since this story was originally posted, Lithoz has also begun to offer a new material called LithaBone HA 480, a hydroxyapatite option for bioresorbable bon implants.)

“We want to make people think about the possibilities…”

“[The surgeon] can even make more than one implant for the same patient so he can be sure that if he has to take more cancerous bone away that still he has a perfect fitting implant,” Bomze says. The ability to ensure a perfect fit “also can drastically reduce the time in the operation theater, which is a benefit for the patient and at the same time helps reduce costs.”

Even if this literal jaw configuration is never used in a patient, Bomze and his fellow researchers believe in it as an effective case study.

“We want to make people think about the possibilities that come with LCM technology, and about solutions for their problems which are now possible with Lithography-based Ceramic Manufacturing which have not been available so far,” he says.

Related Content

View From My Shop: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreRead Next

Printing End-Use Parts from High-Performance Ceramics

The lithography-based ceramic manufacturing (LCM) process allows the cost-effective production of ceramic parts even for a batch size of one.

Read More"Stereolithography for Metals" Produces Detailed Parts

Lithography-based Metal Manufacturing (LMM), a new technique developed by Incus uses a curing process based on stereolithography to build green metal parts with photopolymer.

Read MoreTopology Optimized 3D Printed Spine Implant: The Cool Parts Show #2

Medical contract manufacturer Tangible Solutions shares a titanium 3D printed spine implant with an unusual lattice structure in this episode of The Cool Parts Show.

Read More

.jpg;width=70;height=70;mode=crop)