How Test Swabs Became 3D Printing's Production Win: The Cool Parts Show #15

Nasopharyngeal swabs for COVID-19 testing are one of the best production cases for 3D printing we've seen, pandemic or otherwise. Why AM is winning on speed, functionality and collaboration.

Throughout the coronavirus pandemic, we’ve seen additive manufacturing step up. We’ve seen 3D printing used to make face shields, door openers, masks, protective eyewear, even ventilator splitters. But there’s one 3D printed item that tells perhaps the best production story additive manufacturing has ever seen: nasopharyngeal swabs, the critical tools needed to diagnose COVID-19 cases.

The story is a valuable case study for 3D printing in production for several reasons — the first of which, clearly, is quantities. While previously we’ve waxed optimistic about production quantities in the thousands or tens of thousands of 3D printed parts, additive manufacturers together are ramping up to make millions of these swabs per week. But it’s more than a numbers game. Testing swabs are an instance where 3D printing can make real improvement to both the product and the process by which they are manufactured. Watch the episode and see the links below to learn more; this video is part of a series on how AM is advancing during the pandemic.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Resources and links

- PrintedSwabs.org

- Our test swab coverage in past video updates from the weeks of April 6 and April 13

- Recent stories about Origin’s DLP technology and focus on materials

- The Spectrum Dental Printing episode of The Cool Parts Show, and more on this dental 3D printing lab

- Our past feature on Resolution Medical

Transcript

Stephanie Hendrixson

Throughout the coronavirus pandemic, we've seen 3D printing used to make face shields, masks, even ventilator splitters. But the best production story to come out of this time is actually nasopharyngeal swabs. We'll talk about it in this episode of the Cool Parts Show.

Pete Zelinski

This episode brought to you by Carpenter Additive. Carpenter reorganized in response to the Coronavirus threat, literally wrote the book on COVID-19 safety. Stay tuned to the end of the episode. I am just about to have a conversation with Carpenter chief technology officer David Graf, about the tactics that Carpenter deployed to keep employees safe while they continue to produce in spite of COVID. Now back to the show.

Pete Zelinski

I'm Pete Zelinski

Stephanie Hendrixson

I'm Stephanie Hendrixson.

Pete Zelinski

We are with AdditiveManufacturing.Media. And this is our show, The Cool Parts Show, where we talk about cool 3D printed parts showing what additive manufacturing is making possible for part design, product design and also for the future of manufacturing.

Stephanie Hendrixson

So typically in each episode we focus on one specific 3D printed part. In this case, in this special episode, we are going to be talking about sort of a class of 3D printed parts. These are 3D printed nasopharyngeal swabs that are being used for COVID-19 testing. So we should say that we are adhering to social distancing guidelines right now, it looks like we're sitting side by side, but actually it's two different cameras. We're sitting at two different ends of this table and it's just edited together to look like we're sitting next to each other.

Pete Zelinski

So nasopharyngeal swabs, maybe the most significant part we've had a chance to talk about on The Cool Parts Show. Significant because it's timely. We are in the midst of the COVID-19 crisis and our ability to come out of this crisis and get back to normal is in part going to depend on our ability to do testing, lots and lots of testing, a lot of these swabs will be needed. But also significant because of the way it speaks to a theme that has run all through this show and all through what we cover on AdditiveManufacturing.media, which is the promise of 3D printing for scale production. We've talked about production parts being made through 3D printing, and we've gotten really excited with good reason about parts made by the thousands by the 10s of thousands. Here's a part that's gonna be made through 3D printing by the millions by the 10s of millions, maybe the greatest production scale additive manufacturing story so far, it's like in this future, we're jumping ahead into the future of manufacturing. But But let's take a step back first, these swabs. Stephanie, why are these swabs so important? How are they used? What are they for?

Stephanie Hendrixson

Right so these nasopharyngeal swabs or NP swabs are used in the COVID-19 testing process. There are other ways of swabbing, like there are nasal swabs, throat swabs, but these are supposed to be the most reliable. So if you are getting tested a healthcare professional would take one of these swabs and insert it through your nose to the back of your throat, they have to twirl it around to get a good sample. And then if you'll notice on these there's a there's a break point so they actually break it off into a vial to ship it to the lab. So not the whole thing goes to the lab. So conventionally these would be made with injection molding like a plastic shaft and then you would have some kind of like rayon or polyester flocking. But you can see the 3D printed ones that we're going to talk about today. They are all one piece one material. And I do want to take a moment here just to say that all of the swabs that we're going to be talking about and showing today have gone through clinical testing. They are available for shipment. A lot of them have come out of the PrintedSwabs.org consortium, which is a group of printer builders that have come together to develop and prove out these these swaps. So these are all real parts that we're talking about today.

Pete Zelinski

So a tool, a device typically made through injection molding, as you said, typically made through a conventional production manufacturing process that has the strengths and the limitations of that conventional production. There's a couple major suppliers for the standard version of these swabs. One is in Italy and in area very hard hit by the pandemic. There's another in the U.S. in Maine, a company called Puritan. And both of them face the kind of manufacturing limitation we've seen with medical supplies throughout this crisis, which is a conventional production process or facility. It's designed made for a certain maximum production volume and in an emergency, it is very difficult to scale up quickly into higher levels of production volume. 3D printing doesn't have that same limitation. 3D printing is providing a response. Why is 3D printing so important here? Why is that? Why is that the answer?

Stephanie Hendrixson

Yeah. So just to throw out a couple of numbers. So Puritan, the company that you mentioned in Maine, they have the capacity right now to produce 20 million of these swabs per month. So let's say 5 million a week, they are working on expanding their capacity, they want to double that number. But there have been estimates that we might need as many as 30 million of these swabs [per week] to do enough testing to be able to open the country up and know that we're flattening that curve. So 3D printing is helping in terms of quantity being able to kind of pick up that production. It has a couple of other real advantages, though. So like we mentioned earlier, the printed swabs are just one material so there's no extra assembly. There are a tooling list process like you were hinting at. If you're injection molding, you need a mold. And if you want to increase your production, you probably need more molds. So that's that's a holdup. And 3D printing is also a really digital process. So if you have the right printer, the right material and the part file, you can make these parts. And what we're seeing is a lot of the printer builders are sort of activating their user network and having their users make these swaps because it's easy to distribute production by just distributing that part file.

Pete Zelinski

So swabs made through 3D printing. They're not just 3D printed versions of exactly the same swab that was made through injection molding. The swab has to be redesigned for 3D printing basically reinvented for this process. The swabs, designed for the process then have to go through validation to make sure that they're effective, the new designs are just as effective as the old designs. And that speaks to another advantage, I think of 3D printing, which is the chance for rapid product development. You can conceive a design make a part, test that design, tweak it, make another keep on iterating design after design after design quickly to get to where you want, even make different iterations, different possibilities in parallel. Do a lot of parallel development all at the same time by printing a bunch of design ideas all at once. That is the way that the 3D printing response has played out. And the way we got to a 3D printed swap designed very quickly. One of the companies involved in this is Origin. Origin makes production scale 3D printers, 3D printers for industrial production, and Origin now is devoting the machines it has in its own facility to swab manufacturing. Origin has very quickly become a nasopharyngeal swab manufacturer at scale, Chris Prucha is CEO of Origin. And he talked a little bit about that rapid design development process and how that played out with their 3D printers.

Chris Prucha

Everybody actually has their own own design. Formlabs was the first out of the gate. And then BIDMC, which is Harvard's affiliated medical center, created this open project around 3D printed swabs, and there's a lot of sharing of knowledge, you know, the best designs went to their phase one trial for safety. And then the phase two which was sterilization and scalability, can you actually manufacture this thing as a medical device at scale, and then phase three was is this a safe and effective alternative to the NP swabs that are traditionally manufactured and through that process, you get this funnel and at the other side, in the BIDMC study and clinical trial there was Carbon, Envisiontec, Origin and HP all had working swabs that had a, you know indistinguishable concordance from the traditional swabs. So that means that they work as well as the traditional NP swab. And they were all safe. And so that was a pretty major landmark study, especially getting a clinical trial done so quickly. In combination of designing the product at the same time, in basically an open away. That consortium of companies joined with Formlabs and actually Desktop Metal, Ric Fulop, to be able to get all of our swabs to wherever they're needed. And so we as an industry, we can provide, you know, more than 10 million swabs per week. So the advantage when you look at the 3D printed product is you know, We're able to print 1500 of these at a time in less than eight hours. And so essentially, you're, you know, across 50 printers, which is what Origin has deployed, you're producing many, many swabs per second.

Pete Zelinski

So the conventional process is injection molding. And the way to scale up production with many manufacturers working all at once in injection molding, the only way to do that is if they all have a mold, everybody's got to have mold tooling in order to be producing in parallel. That's a limitation. And that's not a limitation of 3D printing of additive manufacturing. To scale up production there, and to get a lot of manufacturers involved, you just have to share the digital file. You keep sharing the digital file, and the more people you send the file to the more can be involved in production. It is why additive manufacturing so scalable, and part of the reason why it's a response to this crisis.

But we should say when we talk about 3D printing, because we're getting some first time viewers, and we're maybe even getting some who are thinking about industrial 3D printing for the first time. So we're not talking about 3D printers, like the kind of machines you might see on your desktop that a hobbyist might use. And we're not even talking about 3D printing that's the form of a single nozzle, extruder, laying down material layer by layer. There are industrial 3D printing processes and industrial machines for scale production, additive manufacturing. And this is what you and I think about this is what we write about. This is what Additive Manufacturing Media is all about. So why don't you talk about that? Can you talk about some of the industrial 3D printing processes that are really important for making swabs?

Stephanie Hendrixson

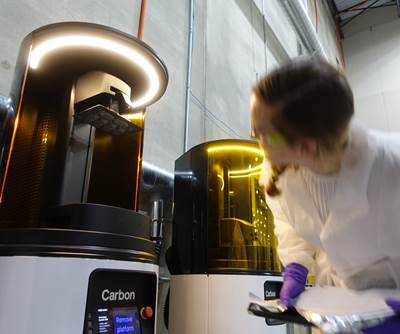

Right, so we're really seeing two different kinds of printing technology being used here. So the first is the resin based printers that use stereo lithography or digital light processing to cure liquid resin So these machines will have a vat of resin and then usually the build plate is is hanging above it. And then as the resin gets cured it rises and the parts are hanging down Upside down from that build plate. So these are the printers from Carbon, from Origin, Envisiontec, Formlabs, all of which are being used to make swabs right now. So the other process that is being used is actually really different. It's multi jet fusion, which is HP's proprietary process. So this is a powder based process where you have powdered plastic in a bed, the printer is dropping a fusing agent, kind of like a binder jetting machine onto the plastic and then it's getting fused with infrared light. So two different processes, differences in design of the swabs based on the different processes and we'll see some of those some examples of that.

Pete Zelinski

So yeah, let's pick up on that. Let's talk about design. The the conventional swab is a molded portion with a with a fabric flocking at the end. And this is a single 3D printed form that that accomplishes all of that. So, again, these are not just 3D printed versions of exactly what was made conventionally had to be redesigned for 3D printing to accomplish the same needed functionality. And there's a lot of aspects of that. So what's needed? A rigid handle, but then less rigidity in the compliant part of the swab, that needs to go into the patient. A head that collects the sample, there is this 3D printed lattice form that takes the place of what the flocking accomplished and serves exactly the same purpose. And there is this break point, the swab has to break because only the upper end is sent on for analysis the handle becomes superfluous at that point and can be thrown away and that break it has to happen cleanly when it's needed easily when it's needed, but never happen accidentally, it can't happen as part of the test. So the rapid design development of this product, that's what it was all about. It was about tweaking it, redesigning it, getting this form just right so that it operates just as well as the conventional swabs do. had to go through clinical testing clinical validation. Most of these swab designs have gone through that validation as this one has at the Beth Israel Deaconess Medical Center in Boston.

Stephanie Hendrixson

So there are five validated designs that we know about and so actually Chris Prucha from Origin told us a little bit about those different designs.

Chris Prucha

So we've been a partner with nTopology, and they have a really, really great generative design software product that that we had—Origin has—been using for many years and have seen evolve. And we were able to work with them to design from the ground up a parametrically designed swab. And what it effectively allowed us to do, because we weren't starting with an existing part, the entire part was designed on nTop platform where everything was parametric. So we could tweak the, for example, you know, things like, you know, you have to break this swab, it has to break into a vial. And so we were able to have parameters around how the breakpoint works. So we could print a variety of different breakpoints with our print process and materials and tweak it, so it's perfect. And then we're able to do the same thing in terms of the tip design, which is a lattice, you know, what are the dimensions of the tip design? You know, what are the rules that that lattice follows what type of lattice cell size parameters. I mean, dozens and dozens of parameters that we're able to manipulate. And then that tip is connected to a sort of flexible deck, which has a taper and again, all of that is parameterized to control the design of this product.

And we actually did a design experiment, when the original product was designed, we were able to design more than 20 variations of the swab and print them all at once. And we submitted them to the phase one clinical trial. And we're able to sort of through like, almost like a version of natural selection, choose the best one. And then from that version, we were then able to make another set of iterations to that, that that best design, and then we chose the best one there. And then we had two candidates to send to the phase three clinical trial. And, and because we could spool up production of the swabs by the thousands, we were able to, to submit two samples to the clinical trial, and they're able to just decide which one to go with that was more promising and that was the one that entered the phase three. And so this is a totally new way to develop a product. You know, it's not just generative design. This is about rapid iteration with feedback in parallel. And this is the kind of stuff that we see, you know, I used to work at Apple. As a software engineer, what you see in the software world, you make 20 variants, and you put it out there, you get the data. And then you iterate really fast. And we did that. You know, in this case, we did it with a medical product in a clinical trial, and I think this is the first, you know, parametrically designed, fully parametrically designed medical product.

Stephanie Hendrixson

So we have in front of us two different examples. So these are the Formlabs swabs. So one of the first designs that came out and they have sort of this like textured tip for collecting the sample. The ones that you have are the Origin swabs that have the lattice. The Envisiontec and Carbon swabs look kind of similar, and then the HP swab is totally different. It has sort of this like spiral on the end, which I imagine is a little bit easier to print and clean with that technology.

Pete Zelinski

So Formlabs, Origin, Carbon, HP, Envisiontec, you're giving names of companies that make 3D printers these are these are makers of industrial additive manufacturing technology. Is it just these machine builders that are producing swabs? Or is there is there more going on than that?

Stephanie Hendrixson

Right, so there's a real mix. So Origin like we talked about earlier, they are making swabs at their production facility. There's a lot of builders that are kind of doing a mix where they're making some of their own. Formlabs is an example, they have a facility here in Ohio with 200 printers where they're printing swabs, but they're also using their customers to make these swabs as well. Another case, Carbon kind of put all their support behind Resolution Medical, which is a key customer of theirs. Resolution actually designed the Carbon swab and they are processing the swabs that all of the other Carbon users are making in addition to the ones that they're making themselves. In the case of HP, it sounds like a couple of key service bureaus like Fathom and Forecast 3D are going to be the ones actually making the swabs.

Pete Zelinski

Okay, so, so already just with you the list that you were able to remember, that's a lot of companies involved, what can you say about the kind of the quantities of production that this is all going to add up to?

Stephanie Hendrixson

So it's, it's distributed amongst all these different places. So it's a little bit hard to kind of get a grasp on it, but just two examples. So Origin has 50 printers running at their facility. They have a really automated process for how they clean and post-process these, they're saying they can make 1 million a week just at their facility. For comparison, Resolution Medical is processing 1 million swabs per week, but that's the one's that they are printing on their six printers, plus all of the other Carbon users that are contributing to that effort. So it's spread out. The estimate right now I think, is that all of the 3D printing efforts combined will produce something like 10 million swabs a week.

Pete Zelinski

Okay, so I want to pick up on something you said at the beginning of that you said it's distributed, right? This is distributed manufacturing. And that speaks to a subtle but important point, which is, there is no big swabs factory. There's not even a couple different swabs factories. There are all these different manufacturers, additive manufacturers, together, producing all at the same time. And some of them are big with lots of 3D printers, and some of them are small with just a couple 3D printers. But as widely as that digital file can be distributed, that is how wide different manufacturers can be brought into this production together. And as you mentioned, it's distributed so broadly, and it's so organic, that it's hard to get your arms around even how much production is happening right now. But as long as you've got the right kind of 3D printer for the design that's been made for the part file that's been made. Anyone with the right kind of printer can get involved in this effort. And that distribution of manufacturing is what has allowed us to essentially reshore swabs manufacturing in just a matter of weeks.

Stephanie Hendrixson

Yeah, so it's slightly more complicated than just the right kind of printer. You also need to have the right materials. These swabs are class one exempt medical devices. So you do need to be registered with the FDA. But the point stands, you know, if you are set up with the right materials, the right kind of printers the right kind of process, you can make these swabs. So it actually turns out that dental labs are really well suited to doing this kind of work. So you might remember we did an episode recently about Spectrum Dental, the printing lab in Columbus, Ohio. Do you want to just recap what we talked about?

Pete Zelinski

That episode focused on the development of a mouthguard customized to the patient. But I think what's most notable here is a dental lab is already making products that go into the body, just like this swab.

Stephanie Hendrixson

Right and so actually these swabs that I have in front of me these were printed on Formlabs printers at Spectrum Dental Printing. So I reached out to them to find out how they got involved in this project. And this is what Sarah Wells and Dr. Bradley Purcell had to say.

Dr. Bradley Purcell

Formlabs reached out to us for facilities that were equipped to handle some FDA compliance issues but also volume needs to be able to print the nasopharyngeal test swabs for COVID for hospitals since we'd had a shortage on testing. And so we got early on into that. And so we've been printing, we’re capable of printing about 1,200 a day. And the tough part there is it's like being a startup company we've had to try to find accounts.

Sarah Wells

I think we were at the advantage because we have already been using, you know, biocompatible materials. Where some of the bigger manufacturers used to be able to use those, those resins. But this is one build platform on the form. So we can get about 324 at once, this takes 15 hours, so you know, one round a day, so with all our printers we can do about 1200.

Dr. Bradley Purcell

You know, as part of that process we had to 3D print our own curing box.

Sarah Wells

So as you can see here there's a ton of them, you know, and one of the issues they were running into was trying to cure all of these, they're bending or warping. So our design came from Formlabs in collaboration with University of South Florida and someone there came up with kind of a curing box design. That's on these little posts. I have it disassembled at moment. But it sits on these posts you can just kind of wrap them all on here and then cure them straight so that they don't they don't warp or bend.

Stephanie Hendrixson

So Spectrum is one example of a dental lab, of a 3D printing user that's been called into this distributed network of additive manufacturing for swabs.

Pete Zelinski

So does this solve the problem? All this manufacturing, all this making swabs, does this address the need for testing COVID-19?

Stephanie Hendrixson

So that's a good question. And swabs are really important. They're critical to this testing, but they're not the whole problem right now. If you think about what comes in these test kits, you have the swab, but then you also have the vial for shipping the sample, you have the virus transport medium inside that vial, both of those, there have been kind of hints of shortages. There's also the issue of lab capacity. So having enough equipment, having the right reagents, having enough trained staff to be able to run these tests. So making more swabs is going to get us closer. It's not going to completely solve the problem.

Pete Zelinski

you know, in this in this issue in this story, NP swabs, the way it's interacting with additive manufacturing, what it says about additive manufacturing. I wonder, Stephanie, there's a lot of takeaways, but I wonder if there's anything in particular that that strikes you.

Stephanie Hendrixson

Yeah. So earlier you mentioned reshoring. And and that's a good point. But there's more than that happening. So kind of throughout this pandemic situation, we've seen these instances where the supply chain breaks down for one reason or another. And often it's because there's just one or two major manufacturers of some critical item. We kind of saw that with ventilators. We're seeing that with swabs now. And what 3D printing is getting us to is not just a different way of making these products, a different design in some cases for these products, but it's actually just a different way of doing manufacturing. And if you have lots of smaller manufacturers distributed close to where the product is needed, you end up with a supply chain that's a little bit more secure, just because you have more manufacturers that are in more places.

Pete Zelinski

Boy, that's that is an excellent point, an excellent pickup that there's this whole promise of additive manufacturing that we've seen that a lot of people have seen. We've seen it coming. And it's like, during this time, because of this need, we've leapfrogged ahead into realizing that promise and it and it gives us not just an answer to the current crisis, but a picture of where manufacturing could go and what it could be. We are rethinking how to produce, we're rethinking entirely how to organize supply chains and what it could look like. And if we get to a future in which we are relying on additive manufacturing, distributed manufacturing much more then it leaves us much less vulnerable to the kinds of supply shortages that we've seen this year.

Stephanie Hendrixson

Right. And so distributed manufacturing, it's this thing that we've been talking about for years. It's this thing that we always knew additive manufacturing could do, but because of the coronavirus pandemic, we're removing some of the barriers that we placed in our own way. So this is a situation where all these different manufacturers have come together. They're collaborating with each other companies that otherwise would consider themselves competitors, are working together to make this happen. And I think maybe we'll see more openness, more collaboration like that. And hopefully more distributed manufacturing in the future because of this.

Pete Zelinski

So that's, that's right too. so so yeah, these companies that we've seen in this episode, mentioned in this episode, they compete. And the competition is a good thing, because it's getting us better technology. But there's also an extent to which these different technologies, if they are better able to interrelate and interconnect, it gets us much faster to this to this more sophisticated manufacturing ecosystem that is going to benefit us all.

So I guess that's a wrap. There's a lot to talk about with this NP swab story, a lot of aspects to this story what it says about manufacturing, we've tried to hint at it a lot of it. Thank you for watching The Cool Parts Show.

Stephanie Hendrixson

If you're just now finding the show, you can watch our previous two seasons and other special episodes on YouTube or at TheCoolPartsShow.com. We are working on season three right now. So if you're on YouTube, go ahead and subscribe and click the bell icon to get notified as soon as those are out.

Pete Zelinski

See you soon.

Related Content

3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

Is Your Dentist a Manufacturer?: The Cool Parts Show #10

Dental devices have always been custom, but 3D printing is disrupting how they are made. We go inside a dental lab in this episode of The Cool Parts Show.

Read MoreProduction 3D Printing With Roots in Materials Development: The Origin Story

Production-oriented polymer AM machine uses the same platform with the same range of controls originally conceived for material development.

Read MoreInjection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read More

.jpg;width=70;height=70;mode=crop)