The Technology House (TTH) in Streetsboro, Ohio, has been 3D printing prototypes for more than 20 years. Founded in 1996 with a single stereolithography printer (“Alpha,” still in operation), the family-owned business built a reputation on CAD design, urethane casting and SLA, capabilities it used to help customers design products and get them to market faster. Eventually the business expanded to include injection molding, painting and, in 2008, machining capacity from the acquisition of a local job shop.

With each step forward, The Technology House has moved closer and closer to producing end-use parts, in increasingly greater quantities. But until recently, the possible avenues for production were limited to molding and machining processes. Now, with the addition of Digital Light Synthesis (DLS) printers and auxiliary equipment from Carbon, 3D printing of parts at production scales has become a full reality for the Ohio business.

Founded on Prototyping

Working toward production was not always part of the plan for The Technology House. Founder Chip Gear, CEO, first encountered 3D printing while working as vice president of procurement at Royal Appliance, the manufacturer of the Dirt Devil vacuum, among other consumer products. When he started in this role, the company was prototyping with models made of foam, which meant long lead times in product development. The company was an early adopter of stereolithography for prototyping, however. Observing how SLA took the product development timeline from months down to weeks gave Gear the idea to start his own business predicated on 3D-printed prototyping. And so The Technology House was launched with just one SLA printer and a handful of employees, including Mark Horner, vice president of business development.

Over the years the business has expanded beyond SLA and urethane casting to include injection molding, finishing and painting operations and light assembly. Today these departments are all housed in the 50,000-square-foot Streetsboro building. In 2008, the Gear family acquired a machine shop, Sea Air Space Machining & Molding in Solon, to help pursue more production work. Today about 60 employees work in Streetsboro and about 15 in Solon, including Gear’s three daughters. Lauren Good is vice president of finance and Nicki Gear serves as HR and payroll manager for The Technology House; Tracy Brent is president of Sea Air Space. Though the two companies have different focuses, they share some staff and resources and can pass work back and forth as it makes sense.

A Different Route Toward Production

As the brief history above illustrates, until recently the two routes toward production that TTH saw were injection molding and machining. That began to change in 2014, when Horner first heard about Carbon’s CLIP process at the AMUG conference that year. Coming from a background of familiarity with SLA, Horner was impressed by the technology’s speed, part quality and the durable materials offered. Before long, The Technology House committed to beta testing the technology and began the journey toward 3D printing of production parts.

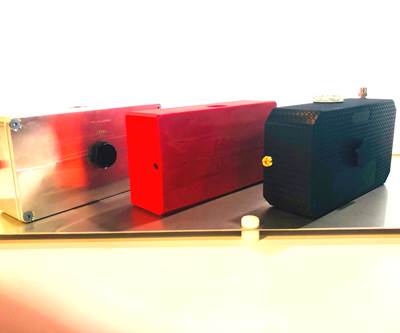

The Technology House currently has three Carbon M1 printers and two M2 printers, which offer twice the build volume of the M1 machines. It is also equipped with a Smart Part Washer from Carbon for automated cleaning, and a meter, mix, dispense (MMD) unit for dispensing resin. Together, the printers, washing unit and MMD form a “SpeedCell” system, a concept of interconnected equipment introduced by Carbon in 2017.

The company’s 3D printing technology, Digital Light Synthesis (DLS), is enabled by the Continuous Liquid Interface Production (CLIP) process. CLIP is a stereolithography-like process that builds parts onto a platform as it rises from a pool of UV-curable resin. Unlike SLA, however, the print process doesn’t pause at each layer. Instead, the resin continuously flows through a “dead zone” just above the oxygen permeable window where UV images are projected to solidify the part. Once printed, the parts are cleaned, their supports are removed, and then (in most cases) they are cured in an oven before being finished to customer specifications.

Production-Ready

In many ways, Carbon’s technology doesn’t just enable production; it practically demands it. The majority of liquid resins used in the system have an 8-hour pot life, which for The Technology House means that unused resin must be discarded at the end of a shift. Therefore, it’s to the user’s advantage to maximize material utilization through careful scheduling to produce as many parts as possible within that window. Other features of the equipment, such as automatic updates and a central control program for managing a fleet of printers and equipment, also encourage users to think system-wide.

“We’re thinking in terms of ‘How many builds?’ versus ‘How many parts?’”

“We’re thinking in terms of ‘How many builds?’ versus ‘How many parts?’,” says Greg Cebular, vice president of sales and project management. The Technology House has found a number of characteristics that make the DLS process suitable for production. They include:

Speed. As demonstrated in the now-famous TED Talk given by Carbon founder Joseph DeSimone, Carbon printers are fast, certainly faster than waiting for tooling to begin manufacturing, but also faster than many other 3D printing technologies. “With these printers, you might print something in 10 minutes, versus several hours with another process,” Good says.

The well-known speed of the DLS printers also presented a challenge that The Technology House has had to overcome. Once printed, the resin parts require between 4 and 13 hours of thermal postcure in an oven—something that customers aren’t always aware of. (Carbon does offer a few UV-cured materials that are ready to go off the printer, but they are most suitable for prototyping applications.) “Managing expectations was a challenge in the beginning,” Good says, but the time savings are obvious when the production timeline is taken as a whole. Rather than wait several months for tooling and parts, customers can have the parts within a week, no tooling required.

Part characteristics. One key advantage of the CLIP process is that the print doesn’t pause between layers, but continuously pulls the build platform upward as resin flows through the deadzone. This means no tell-tale layer lines, but also something more: isotropic properties. The 3D-printed and cured parts are said to be equally strong in all directions, a desirable trait for end-use parts. They are also watertight, a characteristic that not all 3D-printing technologies can achieve without some kind of secondary process.

The printed parts require little to no finishing, and have a fairly smooth surface finish after curing, to the point that they look comparable to injection molded parts. “We show people these parts sometimes and they don’t know how it’s made,” Cebular says. “Aesthetics are important if you’re used to injection molding,” so the surface finish can actually be a tool to help win customer confidence in 3D printing.

Production-capable materials. With many 3D printing technologies, the machine is built and then the material follows, but the DLS printers have been built around the materials, Good says. One of the things that drew TTH to this technology originally was the durable urethane materials available for the system. “Materials are the backbone, the core of the whole thing,” Horner says. “If you don’t have the materials for production, you can’t use it for production.”

Carbon's catalog today includes about 15 materials. Some are “one-part” materials that are UV-curable, but most are “two-part” materials that require a second cure in the oven to achieve their final part properties. TTH prints with all these available materials except the dental resins. Its most commonly used materials are RPU 70, a rigid polyurethane that is UL-rated and biocompatible, and EPU 40, an elastomer suitable for applications including gaskets and Carbon-style “overmolding,” in which the material can be 3D-printed onto an existing build and the complete multimaterial parts cured all together (see Figure 6). Other offerings include materials for high-heat and high-impact applications.

Increasing automation. Whereas manufacturers have had decades to streamline and finesse CNC machining and injection molding, 3D printing still requires a fair amount of human intervention—introducing opportunity for human error, Brent says. The SpeedCell system offers a few features that help take some of that burden away from operators.

One is integration with the meter, mix, dispense (MMD) unit (Figure 5) for dispensing printer resin. Each printer must be stocked with a reservoir, called a cassette, of precisely measured resin before printing. To weigh out the resin by hand takes as much as 25 minutes of human work and attention, but the MMD unit dispenses the proper amount of material in less than 5 minutes. The cassette-based reservoir system also allows for material change-over in a matter of minutes, something that takes up to an hour on the company’s SLA systems.

Carbon’s Smart Part Washer represents another significant labor-saving concession. “Before getting the washer, we weren’t running the printers at capacity because cleaning the parts by hand took too long,” Brent says. Now, employees can load completed build platforms into the washer to be cleaned with a solvent in 7 to 9 minutes. The system isn’t suitable for all parts (thin-walled pieces pose a challenge, for instance) but savings in time and labor on most of its prints has allowed The Technology House to increase production.

Ongoing support. As a beta tester, The Technology House has formed a close relationship with Carbon and offered input on the continued development of the technology. But like any Carbon customer, TTH benefits from ongoing support in the form of training, troubleshooting and applications assistance. For example, when Carbon releases a new material, it offers certifications for that material. Employees like those at TTH can participate in classes and print test parts for Carbon’s review to earn certification, which in turn can help open up new applications and industries.

Carbon is also invested in helping users meet customer price points. The printers allow for some tweaking of the preprogrammed, automatically updated print profiles, for instance the ability to speed up the printing process by adjusting layer thickness. However, for more disruptive adjustments, Carbon can create a custom script to help the user meet the required quantity at a certain price point. This step requires some upfront lead time, but The Technology House frequently finds it’s worth getting a custom script for production jobs. Not only does this result in a more optimized production process, but it also creates a reusable print profile should that job recur.

Current Success and Future Growth

The Technology House is currently capable of turning out about 1,500 parts per day with the SpeedCell setup. While prototyping is still a common application, there is a trend toward customers pursuing production with this technology. “A customer might print between one and ten parts at first, then order 50 to 100, and then thousands,” Cebular says. Within the last six months, the company has started to get more repeat orders, especially for end-use industrial and consumer goods.

In some cases, 3D printing makes sense as an intermediate step between prototyping and injection molding. “3D printing allows us to pursue a ‘dual path’ toward production,” Cebular says, providing a way to manufacture parts quickly while waiting for tooling or while proving out a new product in the market. But increasingly, TTH finds itself manufacturing parts that can actually be improved by virtue of being made with 3D printing.

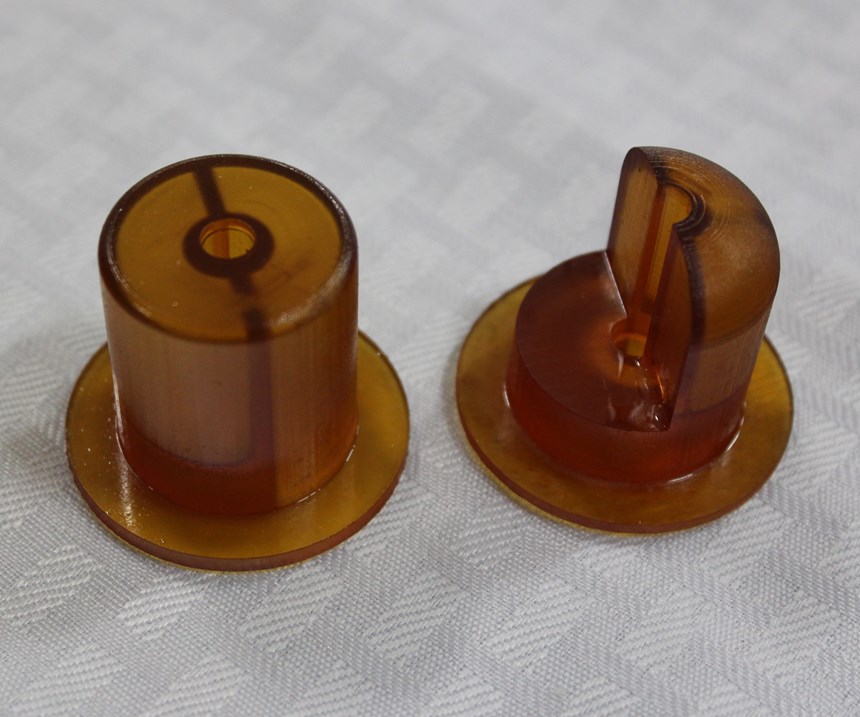

One example is a valve used to control the release of carbon dioxide in wine fermentation (Figure 7). The original component was an assembly of stainless steel welded around glass tubes. The piece was complex to produce and prone to corrosion at the welds. Before coming to The Technology House, the customer had tried recreating the design with FDM, but the resulting part wasn’t watertight. The Technology House was able to recreate the assembly as one 3D-printed, watertight piece using Carbon’s CE 221, a high-temperature cyanate ester material that is said to perform similar to glass-filled nylon. Then, recognizing that the design could be improved, the TTH team made adjustments to the outside geometry of the valve to reduce the total amount of material.

“We can be competitive on tens of thousands of parts. The price is even beating injection molding in certain cases.”

In another recent instance, the company worked with Vitamix to redesign and optimize a nozzle to take full advantage of production 3D printing. The original nozzle design was an assembly of six injection-molded pieces (Figure 9) ultrasonically welded together, used to clean out Vitamix blenders in commercial settings. Initially TTH was tasked with recreating the parts with cast urethane, a challenge because the pieces that direct the water flow include angled, 300-micron-diameter holes that would be difficult to mold with silicone tooling.

The company soon realized it would be possible to deliver the parts more quickly and with better quality by 3D printing them from RPU 70. The 3D-printed parts performed so well in Vitamix’s testing that DLS was selected as the production technology, after which TTH worked with Vitamix and Carbon to consolidate the six-part assembly into a single 3D-printed piece that uses 30 percent less material overall. The one piece also has fewer stress points than its ultrasonically welded counterpart. Other changes, such as squaring off the end of the nozzle to make it easier to twist off by hand, helped to improve its functionality (Figure 9). In testing, the 3D-printed nozzle has proven to be 10 times more durable than the legacy parts while costing 30 percent less, and avoiding the lead time necessary to create tooling. We can be competitive on tens of thousands of parts,” Cebular says. “The price is even beating injection molding in certain cases.”

The Technology House only sees the use cases for its 3D printing equipment growing in the future. When the company first purchased its 50,000-square-foot Streetsboro facility in 2015, the plan was to consolidate both The Technology House and Sea Air Space under one roof. But after bringing in Carbon 3D printing technology, plans changed. The open space in the facility is now reserved not for consolidation, not for bringing machining under the same roof, but instead for future growth in production AM.

Related Content

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreTitanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreBridge Production Is Real Production

Not prototyping — it is something far more than this. The chance to launch the product into the world using additive manufacturing as the initial process delivers important new possibilities, and even keeps on delivering advantages far into the product’s life.

Read MoreRead Next

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreA Global Tooling Manufacturer Goes 3D

Wilson Tooling International turns to Carbon’s DLS technology to reimagine a critical part.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)