Innovative 3D Manufacturing of Franklin, Indiana, has a secret to remaining consistently profitable in metal part production and prototyping via additive manufacturing. That secret is: Do not have build failures.

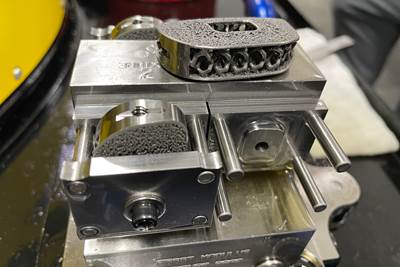

This part illustrates the company's strategy of 3D printing parts with generous extra stock, and also illustrates how this tactic still produces parts that are very close to net shape. On this afterburner component (part of a hypersonic propulsion system developed by customer Velontra), which is seen here prior to machining, a continuous wedge of extra stock around the upper rim supports what will eventually be a thin flange.

Or have as few of them as possible. In laser powder bed fusion (LPBF), the company’s AM specialty, build failure is often the result of distortion from thermally induced stresses in parts for which the process is not yet proven. Build failure is costly in terms of not just wasted material, but also wasted time — easily 10 to 20 hours of 3D printing time that comes to nothing. While build failure is common, in general terms, for first-time builds in laser powder bed fusion, it is not common for Innovative 3D. The contract manufacturer runs 80 to 90 AM jobs per month, the majority of which are non-recurring and seen for the first time. Yet the company’s success rate at printing parts right on the very first time is well in excess of 90 percent.

And a big part of the secret to this success rate, says company co-founder and operations manager Chris Beck, is the way this AM company leans heavily into CNC machining.

I recently spent time at this Indiana additive manufacturer to learn how the business operates, and how it has grown in a short number of years to become a thriving AM part producer, leveraging and generally filling the capacity of a dozen LPBF machines.

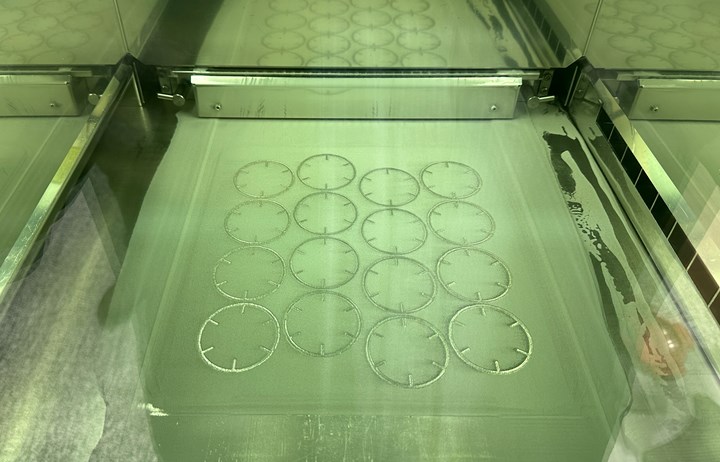

Innovative 3D Manufacturing has 12 Renishaw laser powder bed fusion machines. Most are single-laser models. Four of them, including the one seen in the preceding image, are quad-laser machines.

How to Prevent Build Failure in AM

The way machining aids in controlling against LPBF build failure is simple. To guard against part distortion, Innovative 3D’s engineers routinely overspecify support structures. They also overspecify added stock around 3D printed features. Build failure is so costly that the extra material applied for stability during the additive build is a relatively cheap insurance policy, Beck says. Vertical machining centers from Hurco, Mazak and Toyoda (among other machine tools in the shop) provide ample capacity to support the LPBF work. Even additive parts that are heavy with extra stock still are nearer to net shape than many comparable castings, with less machining work than a casting might require — meaning the extra stock guards the part’s value without imposing significant extra cost or effort downstream.

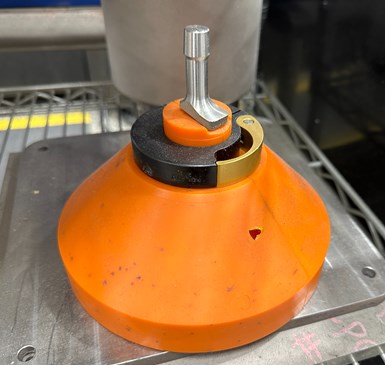

Many of the company's tactics for machining AM parts were learned machining castings. Some casting machining work was being done on the day I visited. The casting here is held using a fixture tailor-made to the form of the part.

Indeed, this reliance on machining in a way that is suggestive of casting is a legacy of the shop’s founding. Beck has worked in die casting, and his co-owner who is not active in the business day to day is the owner of a thriving foundry business operating nearby.

The two founded Innovative 3D in 2017. To visit the company today is to marvel at how far it has come in a small number of years, because the unassuming exterior of the facility (seemingly another industrial building in a southern Indiana manufacturing park) masks the volume and sophistication of the advanced manufacturing being performed inside. Innovative 3D has 12 laser powder bed fusion machines, all from Renishaw, and on any given day, seven days a week, most of the machines are running customer parts. Beck built the business on personal loans, with no venture capital, no investor other than the co-founder, and his own family’s house on the line if the business failed. Perhaps spurred by the owner’s attention to that final point most of all, the business has been profitable through every one of its seven years in business.

A simple milling machine cuts machinable plastic for fixturing AM parts for machining. This fixture will be used to support a part 3D printed in Inconel for a slight amount of machining related to its critical features.

Importantly, though: In that first year while additive activity was still ramping up, it was machining work that made the business profitable. In this way as well, close integration between 3D printing and machining has been a key ingredient to the success of the business.

And if another ingredient has been equally important, Beck says it has been a similar closeness to customers.

Finding Cost Savings in AM Parts

Part of the connection to customers is reputational, he says: concern with the company not just being known, but how it is known. “Always do what you say you’re going to do,” he says, as an operating principle. “Most of our work comes from repeat business or referrals,” so the value of reputation is ever on his mind. This frequently leads to working late or making extra investments in jobs when this is what is necessary to deliver the work according to agreed-upon timing. Whereas shifts in delivery timing are part of the landscape of AM because a larger share of the work it takes on is developmental, Beck aims to stand out for reliable consistency, whether he believes the timing for a particular job is being closely watched or not.

Another aspect of the interaction with customers is consultative: having sufficient access for a shared understanding of the job. In the value Beck places on conversations with customers in the planning stages of a job, his additive “shop” is very suggestive of a machining job shop. Many parts come to him that are suitable for AM, he says, but most of these can be made much less expensive to produce additively with straightforward geometric changes (related to overhanging features, for example), or with an understanding of which features are truly critical to the functionality of the part. Meanwhile, an even larger share of parts that come to the company are not suitable for additive, he says — and it is in no one’s interest for Innovative 3D to take on one of these jobs, even when the customer believes additive is what they want.

Innovative 3D co-founder Chris Beck turns away more additive opportunities than he takes on. The work that fills his AM machines consists of parts very well-suited to additive. Among their shared characteristics are a challenging material (the part seen here is Inconel 718) and performance achieved through a complex or challenging geometry.

Beck declares, “Only about one in eight of the parts we are offered for additive actually makes sense to 3D print.”

For the other seven, his career experience in casting, and in later roles in the machine tool industry, has given him enough knowledge to offer useful direction to the customer in finding a more cost-effective non-additive way to produce the part.

What that means is this: For Innovative 3D, one other part of the secret to thriving at AM for production is being free about turning away opportunities for AM production.

And AM for production is truly where the company is now thriving, where the fastest gains are being made. The picture of what this looks like hints at some of the other practices that are meaningful to the company’s success in this area, as well as some of the more surprising opportunities it sees. Beck sends some potential AM work away to other processes, but then those other processes sometimes send the work back to him.

Supply Chain Opportunities for AM

Recurring production via LPBF is growing rapidly for Innovative. Today, the company’s AM work is 40% production, 60% prototyping or process development. But a variety of production work is set to begin soon, Beck says. Within one year, the production share will be 70%.

The business is one-half aerospace and defense. The other half serves a broad mix of industries including firearms, medical and transportation. The work involves registration to quality systems such as AS9100, ISO13485 and ITAR. It also involves secrecy.

“We are under about 300 NDAs,” he says. This kind of secrecy is characteristic of additive manufacturing, but in Innovative 3D’s case, not all the confidentiality is around new designs. Some of it focuses on old designs. Many producers confronting supply chain challenges related to long foundry lead times have come to Innovative to obtain what otherwise would be cast parts through LPBF instead. In these cases, the part geometry is the same as the cast version, and the part’s material properties are generally better, Beck says. But still, he says companies generally do not wish to bring attention to part substitution that represents a departure from their standard processes. Yet Innovative has performed this kind of bridge production so frequently that Beck can confidently say, “There are way more additive parts out there than you realize.”

Additive production (bridge or otherwise) is where the company’s profits and future are to be found. However, “prototyping is the most fun,” he admits. This is the work the company owner enjoys: optimizing the geometry for an additive build, thinking through the steps necessary to assure that the first build will be accurate. He gets to do this work less and less because of the demands of leading a growing business; today there are three engineers doing this work, spending each day preparing what will generally be the next day’s builds. In the history of the business so far, Beck says, “We have produced more than 12,000 part geometries through additive.” And again, not all of that was designed for additive, because some work — a substantial share of recent work — has been parts intended to be made through casting.

Of the dozen Renishaw AM machines, two have been with the business from the beginning. He displays the performance history of each machine — the two oldest have delivered more than 1.5 million layers of 3D printing apiece. Eight machines, including the two oldest, are single-laser, while four newer machines are quad-laser. To prevent lost time for material changeover, the company tends to leave all machines dedicated by material; the lineup includes multiple stainless alloys, multiple Inconel alloys, cobalt chrome, titanium, aluminum, and more.

The company employs a total workforce of just 12 including Beck, and it runs seven days per week. The work week is five 10-hour days, plus a few hours apiece on Saturday and Sunday for whatever manual intervention is needed. Friday is the busiest day, because this is when the team sets up for long build cycles through the weekend.

I was there on a Tuesday. While walking the shop floor with Beck, I asked him: At midnight tonight, how many LPBF machines will be running producing parts? He thought about the current active jobs, looked up and down the line of machines, ran a quick tally in his head and said, “Nine.”

That is, on a representative workday, 75% of the additive capacity is engaged in commercial work. The company did not always have this much activity for AM.

More Ways AM Connects to Machining

A machine shop that is organized around the needs of additive manufacturing is also a shop that is apt to be good at sophisticated tooling and prototyping work. This precise tool (a set of two parts) is an example of the kind of machining work the company specializes in that does not relate to AM.

Finding work for the additive machines was difficult in the first year, so job-shop machining with no connection to additive was the primary source of income. For an AM provider, this is one of the most basic ways machining connects to additive: as an alternate path, a means of income between or before the AM opportunities. Today, by contrast, almost all Innovative 3D’s machining supports additive, and that brings out many more connections between the capabilities. Here is what the company is demonstrating about the ways metal 3D printing and machining go together:

Turning is not typically thought of as a postprocessing machining operation for additive parts, but these Hwacheon lathes do a surprising amount of AM-related work. Some 3D printed firearms parts are cylindrical. Other AM parts are made cylindrical via tooling for faster machining (see next photo).

1. Machining of castings is preparation for AM. Capabilities relevant to machining castings provide effective tactics for machining additive parts. Both types of parts are characterized by organic forms that do not offer a flat clamping surface. Just like in other shops that perform finish machining of castings (which Innovative 3D also sometimes does), the shop here has a milling machine cutting tailor-made workholding out of Renshape machinable polymer to support odd-shaped workpieces that, in Innovative’s case, are made from 3D printing.

This 3D printed implant is mostly hidden inside the fixture seen here created by Innovative. The implant is not cylindrical, but the critical machined feature of it is. Holding the part inside of this fixture allows it to be quickly machined in a lathe.

2. In metal AM, leaning into machining makes more sense than avoiding it. Again, because a failed build potentially ruins the profitability of a job, extra stock is inexpensive insurance. Compared to casting, even the additive part with generous stock left for machining is nearer to net shape. (Compared to a machined hog-out part, forget about it.)

3. AM’s workflow makes for a great prototyping machine shop. The workflow and complexity of additive parts trains the machine shop supporting this work into the pacing, patience and attentiveness that is well suited to machining complex prototypes and tooling. Many machine shops seek to avoid this kind of one-off work, preferring recurring production. A machine shop oriented to serve the needs of AM is inherently a capable prototyping shop, essentially as a secondary benefit. On the day I visited, Innovative’s machine shop was running a set of tools for an aerospace OEM — complex machined parts with no connection to additive.

A simple but critical machining need of a production additive business is build plate resurfacing. Innovative's production requires it to machine build plates at the rate of six to eight per day.

4. Have we mentioned build plates? Innovative’s rate of additive production results in six to eight build plates per day needing resurfacing. One of the vertical machining centers in the shop is practically dedicated to this work. (Wire EDM for cutoff from the build plate is yet another capability of particular importance to LPBF that is part of the machine shop here.)

5. Machining opportunities can come from additive expertise. Beck says the reason AM can lead to machining opportunities has to do with the way additive provides entrée to vendor lists. “It is hard to get a vendor code as a machine shop,” he notes — the OEMs issuing these codes already know many machining providers. It is much easier to get a vendor code as an AM provider, he says, and then that code applies to any manufacturing work. And while the OEMs do know many machine shops, Beck says they know few that are effective at prototypes or complex tools (see point 3). Once AM begins the relationship, the focus on this type of machining can bring additional work.

Today, one of the larger questions that Beck and Innovative 3D face also relates to machining. The company still takes higher-end machining work, and it runs certain recurring machining jobs for aerospace and medical customers that it won during the time when machining work was a vital share of income. But now that additive work fills the shop’s capacity, and now that the owners see even more additive work to pursue if they are willing to scale, should they let go of the machining opportunities for the sake of more fully directing the company’s energies toward additive?

There is no easy answer. The pure machining work is diversification, another sort of insurance policy. At the same time, it is a distraction — a fragmenting of attention that could be focused on the work the company was created to do.

Check These Boxes (or Not)

In a sense, among the most meaningful factors contributing to success with additive production has been that very success with additive production. The success itself provides a foundation of confidence for turning potential additive jobs away to other processes. Returning prospects appreciate and trust in this. More opportunities thus keep coming, allowing Innovative 3D to capitalize on the one opportunity in eight that makes sense for AM. Part of the way to succeed with AM is to be the manufacturing consultant able to see and speak to all the reasons for guiding a particular part toward a process other than AM.

Time or cost savings is increasingly a requirement customers are looking for in additive work. This is particularly true of parts made additively due to the time constraints of an alternate process such as casting. Speed and economy influence what Beck sees as the ideal size for laser powder bed fusion parts. The best case for production is when a dozen pieces or more can fit on the build plate at once.

Why is just one job in eight a good fit? For a job to make sense for LPBF, Beck says, there are potentially various boxes to check. The part suited to be produced additively in this way is likely made of a superalloy, or some other material that is much easier to 3D print than to machine. It also should feature thin walls or complex geometry. And it needs a design that brings a performance enhancement over the version of the part that could be made conventionally. Plus, if one of the goals of additive production is cost savings — which is more and more often the aim Beck’s company is serving — then the part needs to be sized so that many can fit on the build plate for economical production in a single cycle.

That is a lot of boxes to check. Yet Beck has found there is plenty of work that checks them all. Various firearms industry parts, for example. One instance is a suppressor redesigned for additive; it features complex geometry for improved performance over standard suppressors, and it can be 3D printed in runs of 16 to 24 per build. Bonus: This additive component is easy to postprocess, he says — the cylindrical part gets machined to spec on a lathe.

But then, added to these opportunities lately is the considerable share of parts that check none of the boxes, but still make sense for AM because the part’s established process creates supply chain delays.

“Some people still try to say that additive is expensive and slow,” Beck says. “When I hear that, I just think, ‘That is because you are printing something that should not be made that way.’”

Plenty of parts should be made additively, he says. And when capacity limitations cause other processes themselves to become expensive or slow, the list gets longer.

Related Content

Southern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

Read MoreIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreRead Next

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreSouthern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More

.png;maxWidth=300;quality=90)