Metal additive manufacturing (AM) is different from metalcutting and forming processes in beneficial ways. AM is different because it does not need tooling — a fact that brings new possibilities in terms of geometry as well as potential time savings. It is different because the process of building parts layer by layer generally means less waste is generated, arguably making the process more sustainable. And it is different for its workflow, one that can support on-demand production to reduce inventory and deliver parts as needed. A manufacturer embracing metal additive has more freedoms in terms of design, scale and lead time of production.

Despite these advantageous differences, however, AM also continues to be plagued by another difference: The material properties of a metal 3D printed part are simply not the same as a cast or forged part. One could argue that perhaps they don't need to be; perhaps qualifications and standards based on cast or wrought properties should be reevaluated for additive manufacturing. But another argument says that metal 3D printed parts don’t need to meet these standards as-printed. It may be enough that they meet them through subsequent processes. After all, even foundry parts require downstream steps — and answers for AM parts can be found in processes that already exist.

Aalberts Surface Technologies-Accurate Brazing sees this potential. The company, a global conglomerate of five divisions, specializes in heat and surface treatments, polymer coatings, brazing, and now postprocessing of metal 3D printed parts. That postprocessing capacity includes more than two dozen vacuum and air atmosphere furnaces spread across facilities in South Carolina, Connecticut and New Hampshire. But it is a different process, hot isostatic pressing (commonly known as HIP or HIPing), where the company sees the greatest potential for metal AM parts. While HIPing is already known to additive manufacturers (in particular, those using laser powder bed fusion), the company believes the process has not yet reached its full potential, and that it can be applied with greater effectiveness and economy as additive production scales.

With this future in mind, Aalberts Surface Technology’s Greenville, South Carolina, location is equipped with two large HIPing furnaces from Quintus that command both attention and the bulk of this facility’s additive-focused services.

The two Quintus QIH122 M URC units at Aalberts’ Greenville location provide pressure ranging to 207 MPa (30,000 psi) and have a maximum temperature of 1,250°C (2,282°F).

“Fifty percent of the HIPing work we do in Greenville is for additive parts,” says Craig Beaumier, director of business development. This is by design; while the facility also offers brazing services and vacuum furnace heat treat, it is intended to be the company’s Center of Excellence for postprocessing of AM parts.

Hot Isostatic Pressing and High-Pressure Heat Treat

The HIP process uses temperature, time and pressure to take material to its plastic state and essentially squeeze out any porosity, resulting in material densities up to 100%. The process can be applied to various types of materials, but in the 3D printing space has been used mostly on metal parts, and this is the area of opportunity that Aalberts is focused on.

While many additive manufacturers are already familiar with and even have integrated furnaces for heat treat in their production facilities, HIP capacity is much less common. The equipment is much larger and more expensive than a more conventional heat treating furnace, and requires up to a year of training to operate. Those hurdles, coupled with a scarcity in HIP services for additive, have resulted in underutilization of the process, Beaumier says. For metal 3D printed parts, HIPing offers an efficient avenue to both stress relieve these components and apply other process steps in the same cycle.

Parts to be HIPed are loaded into these cylindrical baskets and stacked on top of each other before being moved into the furnace.

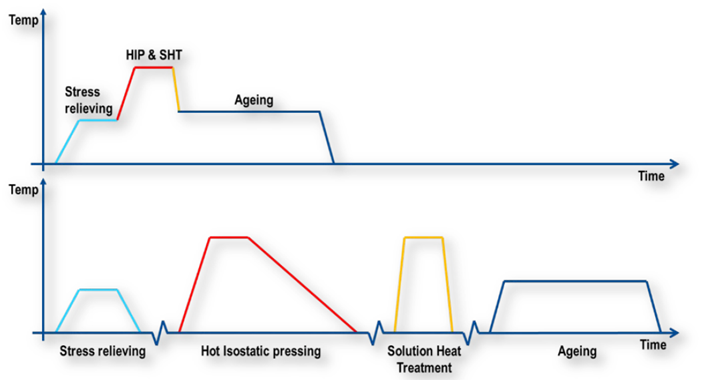

The exact service Aalberts offers with its HIP furnaces is high-pressure heat treat, or HPHT. Parts are loaded into cylindrical baskets and stacked in the furnace (“dim sum-style,” Beaumier says) to be pressurized, heated and cooled to achieve desired material properties. Each cycle is unique to the material and application, and can be modified to impart various characteristics to the parts inside. By manipulating the variables of time, temperature, and pressure, Aalberts can create HPHT cycles that combine stress relief, HIP, solution heat treatment and aging all in one, rather than performing these steps in separate processes.

“We’re taking traditional thermal processing and combining it all in one unit,” Beaumier says. Customers benefit from the chance to leverage one supplier for a range of postprocessing needs, plus reduced lead times compared to sending parts out for piecemeal services; Aalberts’ HIP services have an average turnaround time of about a week. The consolidated process also has potential benefits for the parts themselves; 3D printed components end up spending less time at elevated temperatures with this strategy, which improves process and quality control.

Postprocessing steps with Quintus’ Uniform Rapid Cooling (URC — top figure) and without (lower). Because HIPing can accomplish many operations in the same cycle this way, the process can save time in the overall production of metal 3D printed parts. Image Credit: Quintus Technologies

Recipes for HIPing Additive Parts

Not to say that HIPing AM parts is without its challenges, because the properties of printed metals — that same difference that places hurdles before 3D printed parts entering industry — also pose a ramp-up challenge for HIP.

“Every printer’s a foundry, and they all behave differently,” Beaumier says. While HIPing processes are well-documented and understood for castings and forgings, the “recipes” for additive manufactured parts are still being established. Developing those recipes remains a key to Aalberts winning work for this process, and a problem that needs to be solved at large to bring the broad benefits of HIP to additive production.

“We will run dedicated cycles to show the customer proof-of-concept for this process,” Beaumier says. Right now, the focus is less on throughput and more on developing recipes and winning trust.

As these recipes become known, established and accepted, the use of HIP for production additive manufacturing will grow. At present, Aalberts is running its two Quintus furnaces regularly, and plans to add a third HIP furnace to support growing demand.

Parts are staged for HIPing in this area in front of the furnaces. Today each unit runs about two cycles per day, but can support three when demand rises.

While additive manufacturing technologies will continue to improve at the same time, Beaumier doesn't see advances in 3D printing equipment as a potential replacement for downstream processing.

“Will we ever get away from HIPing? No, not for AM,” he says. “This is affordable insurance on the material,” and a policy that can be relied upon today, without waiting on advances in 3D printing.

Related Content

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreHow Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

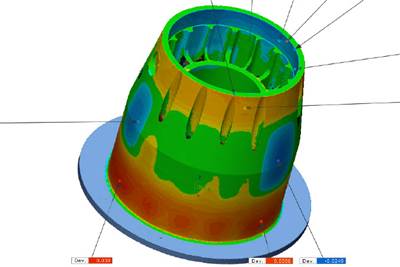

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)