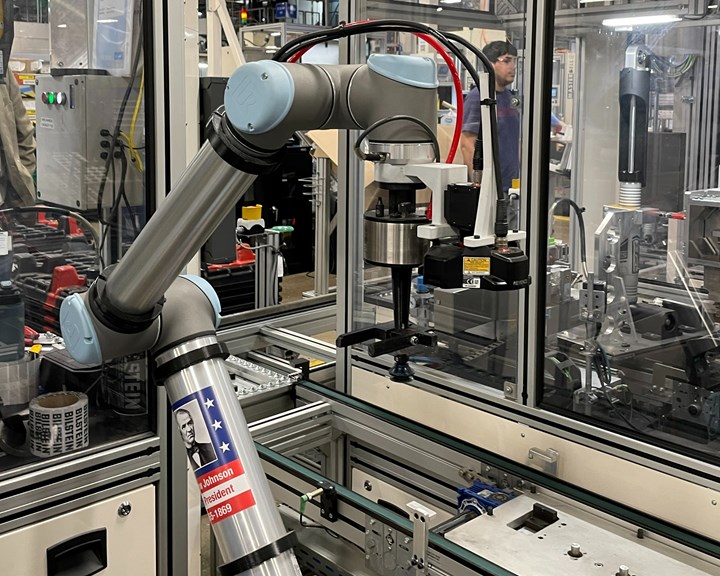

At the Hamilton, Ohio, production plant for shock absorber manufacturer Thyssenkrupp Bilstein, a close look at the facility’s piston rod and valve cell reveals how robots and 3D printing go together.

The piston rod and valve cell at Bilstein's Ohio plant features three collaborative robots. These and other cobots in the facility are from Universal Robots. The next three photos show 3D printed hardware vital to the smooth unattended operation of this cell.

From a distance, the principal feature of this automated cell is three collaborative robots, or cobots, all moving in unison to assemble a spacer sleeve, piston rod and valve components into a subassembly that is clearly on its way to becoming an automotive shock absorber. But come nearer, and the 3D printed hardware comes into view. 3D printed frame sections support the Z rack that positions a small metal tube component where the robot expects to grab it. 3D printed cuffs secure cables to keep them out of the way of robot motion. 3D printed brackets and a 3D printed tower hold sensors in the correct positions. Cobot grippers are 3D printed. There is even a 3D printed handle the robot grabs to open the drawer where it deposits any parts identified as rejects.

A gravity-fed Z tray supported by 3D printed components positions the next spacer where the robot is programmed to grab it. (Click to enlarge.)

All of this is typical for the application of robotic part handling throughout this plant. Every robot application involves custom hardware to some extent. And the need for that custom hardware has intensified, because Thyssenkrupp Bilstein has been automating fast, and extensively. In 2018, recognizing the staffing challenges resulting from a decline in potential manufacturing employees in the local workforce (a challenge Bilstein correctly predicted was likely to grow), the company committed to a plan to advance automation as a way to support the staff it does have by freeing employees to devote more of their attention and time to higher-value, non-repetitive tasks. Initial successes with automation led to more success, as the team tasked with automation at the plant, and indeed all the staff of the plant along with them, has gotten better at recognizing and realizing the operations in which automation can take the place of human effort.

3D printed brackets support sensors at various positions throughout the cell. The donut-shaped seats were initially 3D printed as the cell was being developed and proven out. (Click to enlarge.)

[Related: Read about the advance of cobot automation, including its early failure, in a companion article from Modern Machine Shop detailing four steps to the cobot culture at Thyssenkrupp Bilstein.]

Cuff-like brackets on the cobots keep cables out the way of programmed motion. Some of the robots' grippers are 3D printed as well. (Click to enlarge.)

Cobots have been the enabler to automation’s advance. Relative to other options in automation, collaborative robots are lower-cost and more flexible — in that they are easy to redeploy as needed — and they are safe to use near people with relatively minimal need for safety protections. While not all the opportunities the plant’s automation team has found have involved collaborative robots, most of them have. Today, the plant, which employs hundreds, has 33 cobots in active use that have been installed in the last five years, with several other cobot opportunities under development. These opportunities include newly engineered production cells, which now tend to feature cobot automation from their initial conception. And all these applications require custom hardware to aid the robotic system in performing complex repetitive handling and assembly operations reliably when the cells are left to run unattended.

The need now to develop various advanced cobot applications in parallel, and quickly, means that this custom hardware needs to be produced quickly as well — and iterated quickly. This is why so many of the hardware components of the piston rod and valve cell, just like in other cells performing tube punching, pressing, crimping, riveting, oil filling and other operations related to shock absorber manufacturing, are 3D printed. Correspondingly, this is why the plant needs in-house 3D printing capability and has been steadily expanding this capacity.

33 cobots in the facility are all used in conjunction with 3D printed hardware. The components in the preceding images were made on Raise3D printers such as these.

In the past, these custom hardware items would likely have been assembled from machined components and provided by an outside source. That approach is impractical now. “We can’t be beholden to an outside machine shop to provide us with automation components,” says COO and director of operations Brian Williams. The reason, he says, is because the plant’s order for the item would have to wait its turn in that shop’s queue — and the shop receiving a much larger production order might delay it. Then, once that hardware item was delivered, even if the provider perfectly made it to specification, it might still prove to be not quite right because of a design flaw discovered only by putting the part into use. In fact, even relying on an external 3D printing provider would come with some of these same challenges. To keep up its pace with automation, Bilstein needs to not only quickly obtain custom hardware but also quickly iterate it. As a result, the cobot journey has inherently and necessarily been a journey with AM. Today, the plant’s in-house 3D printing capabilities have even advanced even to include a production-scale platform, a Multi Jet Fusion (MJF) machine from HP.

Due to both the quantity of automation hardware components and customer prototypes needed, as well as the material demands of some of the applications, the plant needed a complement to its extrusion-style printers. This Multi Jet Fusion printer from HP was installed in 2019. Seen here: Eric Sorosiak, Bilstein's engineering team lead for technology and innovation.

Part of the reason for that machine is also the increased rigor required of 3D printed components, Williams says — more on that below. But quantity alone is a meaningful driving factor. Those 33 cobots are supported by 50 to 60 custom-designed 3D printed part numbers, he estimates. Further cobot applications will require newly designed hardware components in something like the same ratio, and most of those components will be produced iteratively through various versions for the sake of refining the design. Meanwhile, this need for AM to support automation components is also competing with other advancing demands for 3D printing within Bilstein. The company’s customers — major automakers working to tailor suspension components to their new car and truck designs — also want to iterate components quickly for the sake of refining their designs. Prototype parts and automation hardware both are produced using a network that connects 14 3D printers dispersed throughout the facility.

The earliest 3D printers in the facility were small and inexpensive desktop machines. Today, professional-quality polymer 3D printers (most still desktop size) enable larger parts, more reliable builds and faster printing of both automation and prototype components. 3D printers in use at Hamilton site include 10 machines from Raise3D and others from Creality, Fusion3 and Markforged. All these machines operate by material extrusion. MJF capability was added in 2019, with the recognition that a different polymer 3D printing method was also needed.

Initially, the prototype work required more durable components made from the strong nylon able to be applied through MJF. While AM is not used to make functional components of shock absorber assemblies, it is used to make components tested for fit in assembly, and just this use can be demanding. But the advance of the automation systems has led to the need for more sophisticated 3D printed components, particularly due to the introduction of vision systems into these cells.

Supporting the optical measurement unit near the end effector of a vision-guided robot is an application where more rigid 3D printed hardware was needed. An ABS bracket made on an extrusion 3D printer flexed slightly under the weight. The bracket seen here was made through MJF. (Also visible in this photo: the label on the robot commemorating President Andrew Johnson. The Bilstein team identifies cobots by naming them after U.S. presidents. Coolidge, Hoover and FDR can be seen in the rod and valve cell image above. More about this practice in this companion article about the cobot culture of this plant.)

Within newer automated cells, Bilstein is using machine vision in conjunction with the cobots to provide them with the capability to successfully grab parts that might be found in various locations or orientations, rather than the object being precisely presented. However, in these applications, the location of the vision hardware itself does need to be precisely known in order to accurately use vision readings to direct the robot. A vision system used on a pick-and-place line within a cell assembling dual-valve shocks illustrates the 3D printing need resulting from this. An ABS polymer bracket made through extrusion 3D printing proved to be not rigid enough to hold the vision unit precisely. Instead, a nylon part made via MJF was needed to support the load without deflection. Thus, the increasing number and sophistication of cobot successes in this plant has led not only to escalating demand in the quantity of 3D printed parts, but increasing demand for the capability of those parts as well.

How Collaborative Robot Automation Succeeds at Thyssenkrupp Bilstein

A companion article on Modern Machine Shop discusses how the Bilstein plant went from a failed automation application to 33 cobot successes in a little over 5 years.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreMultimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreA Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.

Read MoreRead Next

Autonomous Cobot Automation Increases Production 3D Printer Output for Ford (Includes Video)

A mobile robot that travels to each Carbon machine to unload builds lets the automaker run an additional three to four builds per machine per day. Autonomous robots fit well with 3D printing, but their role in production will extend beyond just the additive machines.

Read More4 Ways Robots and 3D Printing Intersect

Four examples of how robotic automation and additive manufacturing both help and are helped by each other.

Read More3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

Read More