Mold Tooling

How to Prepare for the Rise of AM in Moldmaking

Mold builders should consider investing in three key areas to take advantage of the opportunities 3D printing presents.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

WatchIntrepid Automation’s Valkyrie Systems for Industrial-Scale Additive Manufacturing

System features modular DLP technology for a customizable, industrial-scale system for high-volume production.

Read MoreVelo3D Qualifies M300 Tool Steel for Use in Sapphire Printers

The company says the high-strength alloy combined with Velo3D’s end-to-end solution can improve the lifetime of tooling inserts and enhance manufacturing throughput for automotive manufacturers.

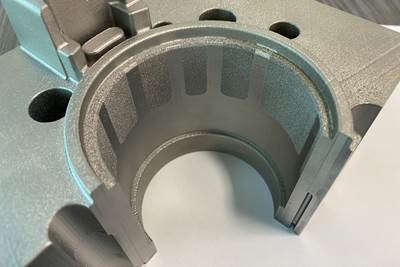

Read MoreDrop-In Solutions Give Users the Benefits of 3D Printed Mold Tooling

3D printed mold components, including ejector pins with venting to eliminate gas traps, can improve performance of traditional injection mold tooling.

Read MoreMantle Metal 3D Printing System for Toolmaking, Prototypes

The technology is designed for easy installation and use so that, with minimal training, manufacturers can have users quickly operating and running the machine.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreMantle Launches Production System, Reveals Equipment

Mantle’s metal 3D printing technology for moldmakers is officially commercial.

Read MoreLinear AMS Merges With Shapeways

The merger is said to enable both companies to better serve their customers’ needs, while accelerating innovation to offer more choices and greater possibilities in additive manufacturing.

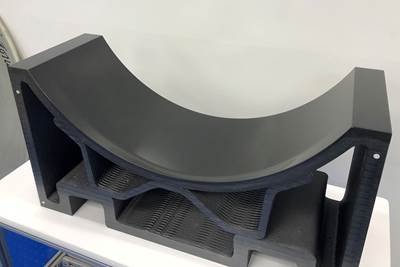

Read MoreAirtech Validates High-Temperature Polymer for Large-Format Tooling, Moldmaking

According to the company, the polymer is well suited for high-temperature applications such as hot forming tools, autoclave molds, oven molds and self-heated molds.

Read More

.png;maxWidth=300;quality=90)