Mold Tooling

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreLightning Round — Recent Popular AM Topics: AM Radio #44

Sporting goods, tooling, multiple materials — in this episode of AM Radio, Jodee McElfresh and Peter Zelinski discuss the topics that have been popular on the Additive Manufacturing Media website and social media recently.

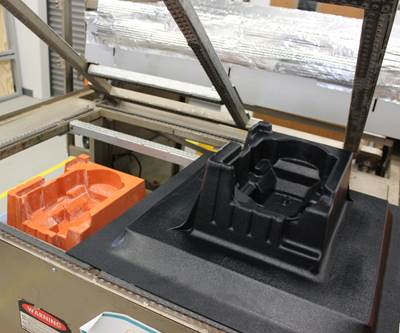

ListenIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read MoreWestec Plastics Partners With Mantle to Speed Tooling Production

Using Mantle's technology, Westec says it can complete up to 70% of the job and have its toolmakers handle the specialized steps only humans can do.

Read MoreCatalysis Additive Tooling Licenses 3D Printed Tooling Technology in Europe

The innoMold company will spearhead the tool manufacturing operating under the name “Catalysis Additive Tooling GmbH,” beginning operations in October 2023.

Read MoreKraussMaffei’s PowerPrint 3D Printer Offers Large-Scale Printing

Companies can purchase KraussMaffei’s large-scale powerPrint 3D printer for in-house production or utilize the company’s print-on-demand service.

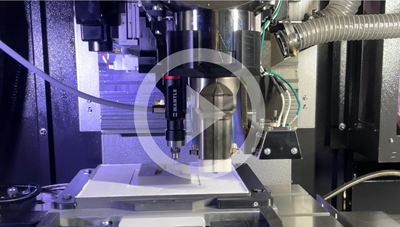

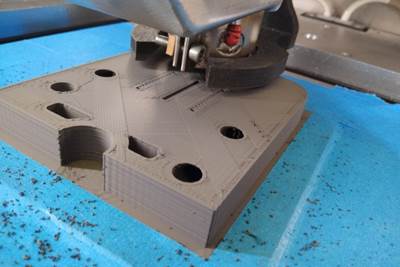

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

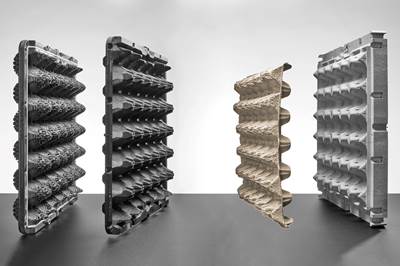

WatchResearch Partners 3D Print MIM Tool With Near-Contour Cooling

Compared to a conventional approach in machining, the use of an additive manufacturing process to produce a MIM tool reduces the total production time from around 8 weeks to approximately 5 days.

Read MoreOmni-Pac, HP Join Forces to Transform Molded Fiber Production, Reduce CO2 Emissions

The companies say this pioneering collaboration will drive digital transformation and sustainability in the packaging industry.

Read More

.png;maxWidth=300;quality=90)