LFAM

Airtech’s Dahltram Resins Approved for Use on All Thermwood LSAM 3D Printers

The company says its Dahltram range of resins are suitable for multiple print platforms, providing production flexibility with end-use material validation.

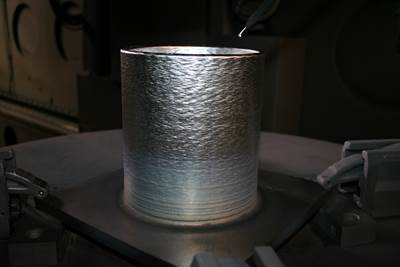

Read MoreThe Way Ahead for Wire Arc Additive Manufacturing

Tooling today, production tomorrow. The capability will advance as value is increasingly seen in lead time savings and design opportunities. Parts that today are cast offer a particularly promising application for a process that is “welding, except not.”

Read MoreFlight Simulator Made Through Large-Scale 3D Printing: The Cool Parts Show #33

Our biggest cool part so far! Printing this massive structure in one piece saves cost and time for L3Harris.

WatchEOS Partners with Morf3D in Applied Digital Manufacturing Center

The center is designed to harness applied research, advanced engineering and application development, serial production and industry partnerships to drive the industrialization of digital manufacturing in high-growth markets.

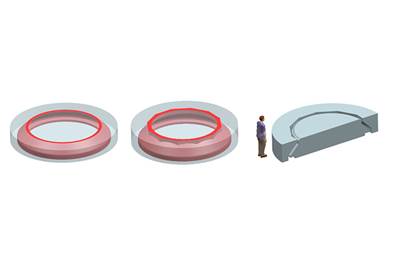

Read MoreResearch Partners Building World’s Largest Sand Binder Jetting Printer

3D printing provides flexibility to produce large turbine components near offshore wind projects, lowering transportation costs and offering environmental benefits.

Read MoreAI to Aid Consistency in Electron Beam Additive Manufacturing

Machine vision and algorithms have helped EBAM users address problems as they occur in deposition, but AI could be able to predict problems before they happen.

Read MoreBigRep’s Shield Large-Format Dry Cabinet Prevents Material Degradation

Cabinet is designed to protect filament from material degradation by eliminating more than 99% humidity, thereby reducing material waste by 20% and repair costs up to 50%.

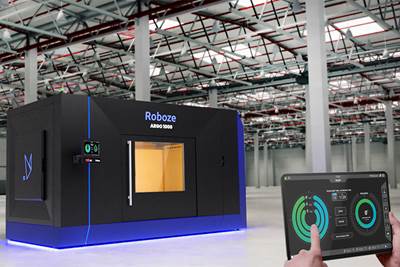

Read MoreRoboze’s ARGO 1000 Fabricates Large Parts Using Super Polymers, Composites

Printer uses more sustainable, high-performing super polymers and composites such as PEEK, Carbon PEEK and ULTEM AM9085F to reduce the strain on global supply chains.

Read MoreThermwood, Boeing, Navy Collaborate on Large-Scale Composite Tooling Research

Thermwood’s large-scale additive manufacturing (LSAM) machine was selected as the large-format additive manufacturing (LFAM) machine to conduct the technology development.

Read MoreMeet the LSAM Additive Printer

Thermwood Corporation, manufacturer of some of the largest composite thermoplastic additive manufacturing systems operating in industry today, has announced the availability of a new line of lower cost "print only" LSAM systems, called LSAM Additive Printers. (Sponsored)

Watch

.png;maxWidth=300;quality=90)