LFAM

Airtech Validates High-Temperature Polymer for Large-Format Tooling, Moldmaking

According to the company, the polymer is well suited for high-temperature applications such as hot forming tools, autoclave molds, oven molds and self-heated molds.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Watch500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

WatchWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreVelo3D’S Sapphire XC 1MZ EnableS Large-format Metal 3D Printing

The printer is designed to significantly increase throughput up to 400% and lower costs by up to 75% compared to the original Sapphire.

Read MoreMassivit 10,000 Additive Tooling System for Composites Manufacturing

Rapid + TCT 2022: The system utilizes the the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

Read MoreThermwood LSAM 510 Additive Printer Useful for Molding, Tooling

RAPID 2022: Thermwood’s LSAM 510 additive printer features a single fixed gantry and a 5 × 10 ft. moving table with a 4 ft. maximum print height and a maximum temperature of 450°C.

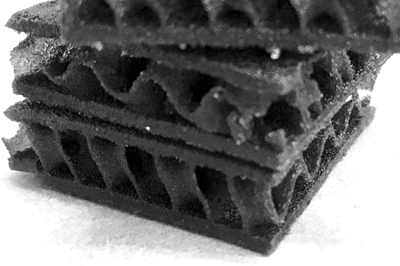

Read MorePrintFoam Develops 3D Printer for High-Throughput Foam Applications

PrintFoam says its 3D printing technology creates closed-cell foam parts that are faster, lighter and less expensive to produce than other photopolymer technologies.

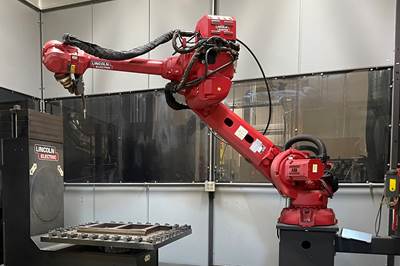

Read MoreLincoln Electric Helps Get Chevron Refinery Back Online

Lincoln Electric worked with Chevron to accelerate refinery maintenance using Lincoln Electric’s 3D metal printing solution.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

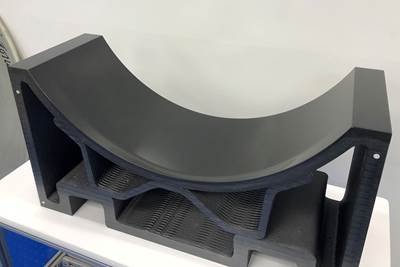

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Watch

.png;maxWidth=300;quality=90)