AM’s Assist to ID Grinding

An additively grown coolant nozzle enhanced the effectiveness of ID grinding. The success hints that additive and subtractive processes might be more complementary than we yet see.

Share

Read Next

Grinding wheel supplier Norton/Saint-Gobain does not make or sell coolant nozzles, but coolant nozzles directly affect how well its own product performs. And in almost every grinding application, says company applications engineer David Graham, the standard machine tool coolant nozzles are sufficient for controlling the grinding wheel’s temperature by keeping it covered in coolant. The exception, he says, is ID grinding.

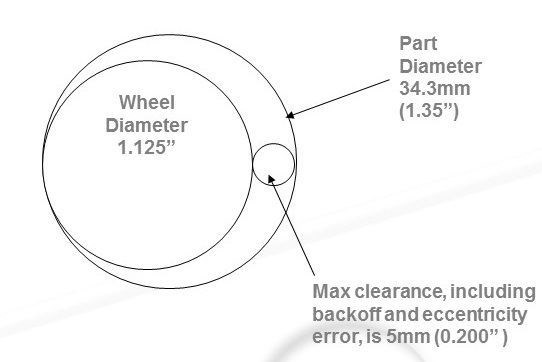

In ID grinding, the inner surface of a bore is machined using a grinding wheel that is typically around 80 percent of the bore’s diameter. A 1.35-inch bore might be ID ground using a 1.125-inch wheel, leaving a clearance (after backoff and eccentricity) of only 0.2 inch between them. During the machining, the coolant nozzle somehow has to deliver the fluid to the wheel and the grinding zone through this small space.

Of course, the nozzle often fails to do this. The difficulty grows even more pronounced as the bore gets deeper. Inadequate cooling in ID grinding thus routinely leads to poor finish, long cycle times and even thermal damage to the part.

Graham was part of an internal project several years ago at Norton/Saint-Gobain aimed at finding solutions to this problem. He says the most effective solution the company found involved additive manufacturing.

Traditional Attempts

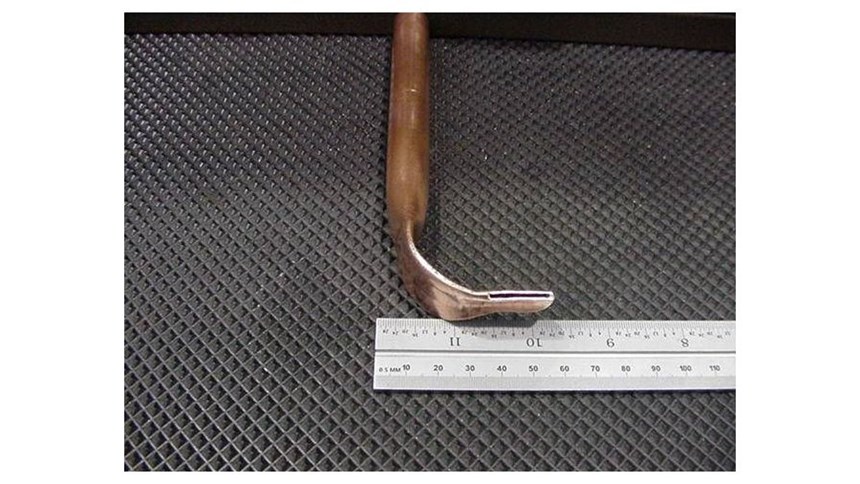

Traditional fabrication methods—forming and welding—were employed first to try to craft a custom nozzle that could reach into the crescent of space between the wheel and workpiece. A “swan neck” nozzle, much like a bent and flattened tube with a slit in the side, was one design able to fit into this space. The nozzle was intended to direct the coolant over the wheel, but it failed to control the coolant direction properly, sending the fluid away from the wheel at an angle.

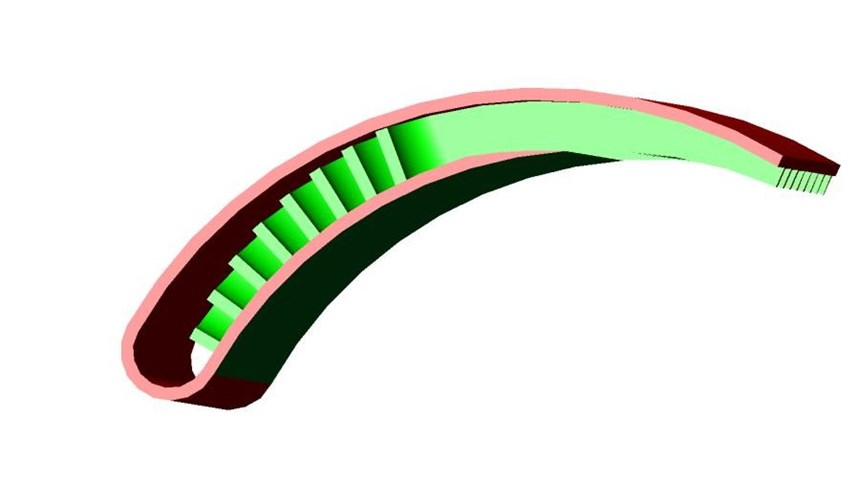

A better design, a “shoe” nozzle, curved along the wheel like a car’s fender, providing ports for the coolant on the underside of the fender shape via drilled holes. This design succeeded at getting more of the coolant onto the wheel, but it also failed to control the direction of flow adequately. Coolant sprayed in various directions, including out of gaps in the nozzle’s welds that opened up because of the pressure.

The difficulty was the result of these nozzles’ lack of any internal geometry engineered to direct the high-pressure flow, Mr. Graham says. As a practical matter, it was not possible to form and assemble a nozzle at such a small scale to include internal passages effective for directing the coolant.

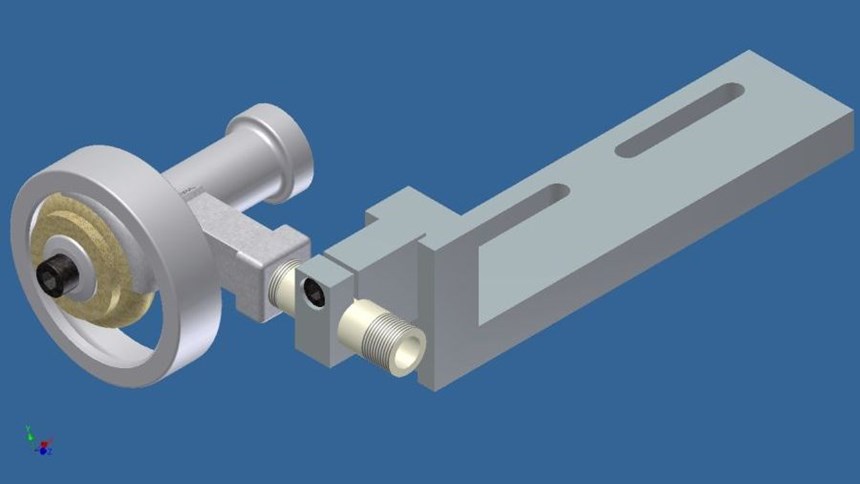

Therefore, the company departed from traditional fabrication. It tried additive manufacturing instead—growing the metal part in one piece. Mr. Graham designed the nozzle he thought would do the job, this time giving no concern to internal complexity, and Norton/Saint-Gobain had this part grown in 17-4 PH stainless steel through direct metal laser sintering (DMLS). Vaupell Rapid Solutions of Hudson, New Hampshire, made the part.

Coolant Control

The design Mr. Graham created is an improvement upon the fabricated shoe nozzle. It uses internal fins within the fender shape to capture and control the coolant. Turbulence is reduced, and the channeled fluid exits the nozzle in a more unified stream that covers the wheel.

Testing confirmed the DMLS nozzle’s effectiveness. During tests in which the grinding wheel’s performance significantly degraded after 8 parts whether it was cooled by the first shoe nozzle or a conventional coolant nozzle, the wheel cooled by the DMLS nozzle continued to perform effectively well beyond this. In a test involving a customer’s ID-ground ball bearing raceway, the DMLS nozzle permitted a 50 percent increase in rough grinding feed rate and a 50 percent reduction in rough dressing passes without any loss to the quality of the part.

Graham says he did have to change the nozzle design. He got the fluid flow right, but not the additive manufacturing. In the part’s transition from the vertical column to the fender, he wanted the passage for the fluid to be as open as possible, but the result was a form that Vaupell thought might be geometrically unstable, failing to build. Mr. Graham compromised by adding supports inside of this chamber, and this design is the one that won the comparison testing.

Again, his company is not in the nozzle business. The aim of the project was to learn what might be possible in ID grinding if effective cooling could be achieved. The DMLS nozzle is not commercially available, but the testing proves that additively manufactured nozzles are a potential solution for ID grinding problems. The plant with a high-volume ID grinding operation that could justify having a nozzle like this made could pursue and implement this same solution.

There might also be a larger lesson in the additive nozzle’s success. The problem of cooling in ID grinding has long been accepted, because the solution—creating a precise, internally complex form able to fit within a tight clearance envelope—was prohibitively difficult with traditional fabrication methods. But additive manufacturing made it easy. Given the geometric freedom that additive permits, it may be time to rediscover other manufacturing problems that we have long accepted and perhaps no longer even notice, because DMLS or even simpler 3D printing might now make those problems easy to overcome.

Related Content

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More