LPBF

Additive Manufacturing for Rail Industry Is Gaining Traction at Neighborhood 91

Locomotive manufacturer Wabtec is the first tenant of Pittsburgh’s N91 additive manufacturing ecosystem, where the company is ramping up production via laser powder bed fusion.

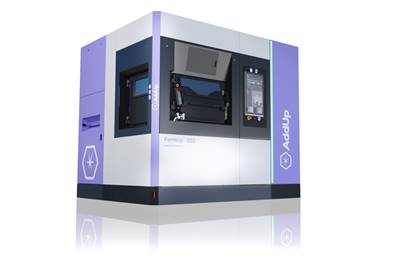

Read MorePrecision LPBF Improves Watch Component Part Performances

Partnering with AddUp has enabled watch part maker Kif Parechoc to use laser powder bed fusion to manufacture parts with improved mechanical performance using less material.

Read MoreVideo: What Is Laser Powder Bed Fusion (LPBF)?

Laser powder bed fusion is likely the most widely used metal additive manufacturing process. Here is how it works, including benefits, issues to consider and applications for this 3D printing technology.

WatchConcept Machine Tool Appointed Distributor for Farsoon Technologies

Concept Machine will serve as exclusive distributor for Farsoon’s metal and plastic laser powder bed fusion 3D printers and additive manufacturing products through nine states for sales, service and consumables.

Read MoreSupport Structures and Build Layout Lead to Series of Fails — AM: Why the Failure? #4

A 3D printed piston crown illustrates the iterative path to success often part of laser powder bed fusion additive manufacturing.

WatchMetal 3D Printed Part Should Be Flat, Has Bubble — AM: Why the Failure? #1

What should have been a straightforward application of laser powder bed fusion to make a simple component in 316L stainless steel turned into a printing fail. See why the failure happened.

WatchMaking a Slow Decision on a Fast Technology: Evaluating the Business Case for Multi-Laser Powder Bed Fusion

A data-driven approach to laser powder bed fusion reveals how companies can get cost out of parts and match productivity to customer requirements. Part Three of a three-part series.

Read MorePushing Laser Powder Bed Fusion into New Realms of Productivity

The Betatype technology stack supports businesses looking to expand on the potential of additive manufacturing for series production through design-led thinking and unique optimization algorithms to maximize the capacity of LPBF systems.

Read MoreDMLS or Polyjet? A Hands-On Comparison to Produce Prototype Mold Inserts

The development phase of creating injection molded parts and inserts often requires the production of small-quantity prototypes. This moldmaker compared two different AM technologies to produce prototype mold inserts made from tool steel and polypropylene photopolymer.

Read MoreDesktop Metal Delivers Mid-Volume Metal 3D Printing System

Shop System is said to achieve exceptional surface finish parts with rich feature detail at speeds up to 10 times faster than those of legacy 3D powder bed fusion technologies.

Read More

.png;maxWidth=300;quality=90)