3D Printing Materials

In machining, a part’s form may change in the process, but its material properties end as they started. In additive, the 3D printing process determines the part's shape as well as its material properties. Variables like processing temperatures, nozzle diameter or laser spot size, gas flow, and more can affect layer adhesion, porosity and density of the final material. The main classes of materials used in 3D printing today are polymers, metals, composites, ceramics and sand

ESSENTIAL READING

VIEW ALLUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

WatchThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Listen10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

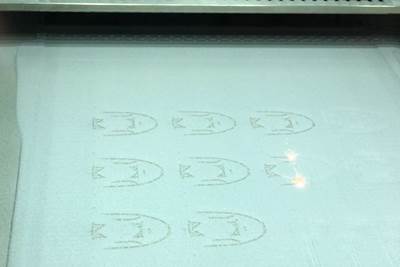

WatchWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

WatchAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

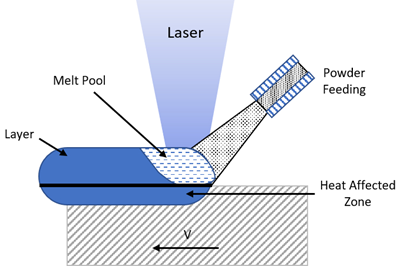

Read MorePowder Comparison: Standards for DED Material Substitutes

What powder properties lead to performance similar to a DED powder? Basic flowability energy, particle density and particle morphology are key candidates.

Read MoreLatest Materials News And Updates

EOS Works With Phillips Federal, Austal USA to Develop CopperAlloy CuNi30 for US Navy Submarine Industrial Base

Using the copper-nickel alloy in combination with EOS’ platforms offers new design and production capabilities for U.S. Navy submarines, while also enabling the agency to limit global supply chain disruption because parts can be produced regionally, locally and on-demand.

Read MoreCRP Technology’s Windform SL Is Lightweight, Rigid Composite for SLS, LPBF

Windform SL is well suited for the the production of sophisticated, efficient components across various fields, from aerospace to automotive, ensuring light weight without the need to reduce thickness.

Read MoreBCN3D Spins Off VLM Business Unit, Creates Supernova 3D Company

The new company’s focus will be on materials development targeting industrial applications, as well as the industrialization of the product ecosystem, with the first beta systems to be installed in 2024.

Read MoreKBM Materials to Distribute Sandvik Metal Powders

The collaboration will increase accessibility of Sandvik’s Osprey metal powders, which includes premium titanium alloys and copper powder, as well as nickel-based superalloys, cobalt-chrome and ultrahard maraging steels.

Read MoreLithoz, ORNL Partner to Advance Processing for High-Temperature Ceramics

The new process could enable laser slurry drying of non-oxide ceramics with high refractive indexes

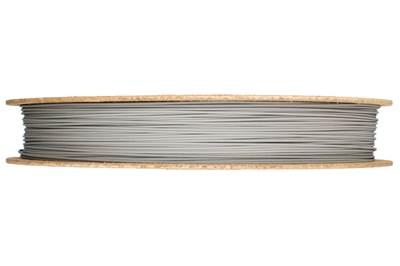

Read MoreVirtual Foundry’s M300 Tool Steel Filamet Offers Strength, Versatility for FFF 3D Printing

The Virtual Foundry developed its M300 Tool Steel Filamet material for fused filament fabrication, offering compatibility with a variety of 3D printers.

Read MoreFeatured Posts

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

WatchThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

WatchUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

WatchFeatured Media

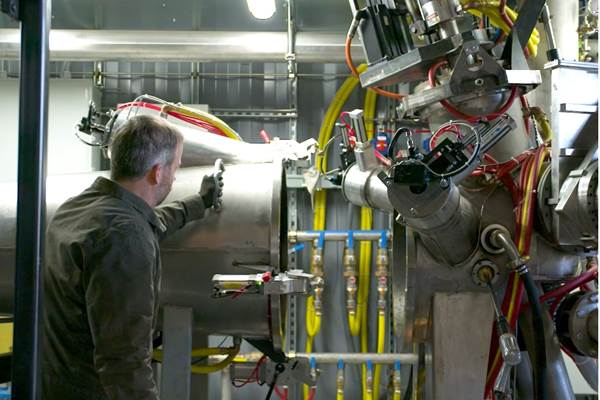

Video: Multimodal Powders for Metal 3D Printing

Rather than uniform particle diameters, multimodal powders combine particles of different sizes. In this video, how and why Uniformity Labs produces multimodal metal powders for additive manufacturing.

WatchFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

WatchThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

ListenFAQ: Materials

Can metal be 3D printed?

Yes. On the metals side, the most commonly 3D printed materials include aluminum, titanium, stainless steel, Inconel and cobalt chrome. Copper has historically been difficult to 3D print with laser-based systems, but innovations such as blue-light lasers make this possible; reflective metals like this may be easier to print using other methods such as binder jetting. An alloy suitable for one metal 3D printing method may not be appropriate for all such methods.

Can sand be 3D printed?

Yes, sand can be 3D printed through binder jetting to selectively adhere the grains together.

What is a thermoplastic?

A thermoplastic is a plastic polymer that can be heated to pliability, shaped either in a mold or through extrusion printing and then cooled back to a solid form. The makeup of a thermoplastic is such that the process of heating, shaping and cooling can be repeated without damage to the material.

What is a metal matrix composite (MMC)?

A metal matrix composite blends a metal alloy with another material such as ceramic.

The composite combines the light weight of aluminum with the strength, hardness and heat resistance of ceramic, making this material a promising choice not only for engines but also for applications in which high stiffness is needed for vibration control, or a low coefficient of thermal expansion is needed because of an extreme temperature range (the case with satellite parts). Yet the material’s very combination of heat resistance and hardness makes it difficult and costly to machine. Additive manufacturing addresses this problem because it is not just near-net-shape (true of a molding), but rather very near to net shape. Source: Metal Matrix Composite Demonstrates Additive Manufacturing’s Promise for New Materials