Directed Energy Deposition

Nikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Angela Osborne

Managing Editor, Gardner Business Media

7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

Read MoreMaking Sense of Data from Directed Energy Deposition (DED)

“It should be easier to qualify an additive part than a casting,” says Formalloy CEO Melanie Lang. The company’s tools for capturing and analyzing data are bringing this vision closer to reality.

Read MoreArcelorMittal Enters Additive Manufacturing Industry With Steel Powder

The company is building an industrial-scale atomizer in Spain to produce high-quality steel powders for multiple additive manufacturing technologies.

Read MoreFinland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreBe a “DED Head?” AM Limitations – Eliminated

DED systems make it easier for manufacturers to integrate additive manufacturing by offering multiple capabilities as well as easy accessibility.

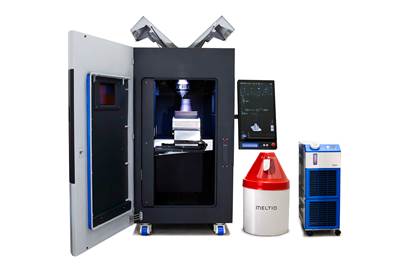

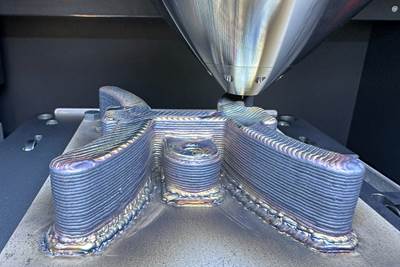

Read MoreMeltio M600 Wire-Laser System Reduces Material Waste, Lead Times While Increasing Manufacturing Flexibility

The Meltio M600 can seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces.

Angela Osborne

Managing Editor, Gardner Business Media

Additive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreDEDSmart Tool Harnesses Data in Real-Time for Build Quality Verification

FormAlloy Technologies’ DEDSmart technology for autonomous DED builds and build data logging utilizes enhanced in-situ monitoring and control, and the power of data, to complete builds autonomously while data logs are automatically exported enabling Digital Build Certification.

Read MoreInfrared Camera Supports Real-Time Process Control for Laser Metal Deposition and Cladding

New Infrared Technologies’ Clamir system provides continuous meltpool monitoring for cladding and directed energy deposition 3D printing.

Read MorePrima Additive’s Ianus DED System for Multiprocess Flexibility

Formnext 2022: The Ianus robotic cell can be configured to perform two different processes (for example additive and laser hardening) in the same machine.

Read MoreDMG MORI’s Hybrid 3D Printer Offers 5-Axis Simultaneous Machining

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Read MoreSee Digital Manufacturing Data in Real-Time

Formalloy showcases a tool for collecting and visualizing data from real builds using powder-based directed energy deposition (DED), a metal 3D printing process.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal AM

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

Robot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreHybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Read MoreAddUp Is Helping Bring Metal 3D Printing to Space

To make additive manufacturing in microgravity possible, the group has chosen to use a process that promotes forces induced by surface tension — wire-laser combination (W-DED).

Read MorePowder Comparison: Standards for DED Material Substitutes

What powder properties lead to performance similar to a DED powder? Basic flowability energy, particle density and particle morphology are key candidates.

Read MoreRobots Combine for Faster DED Build Rate (Video)

The Medusa system merges multiple robots into a single system for efficient additive manufacturing of large metal parts.

Read MoreThe Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Stephanie Hendrixson

Executive Editor, Additive Manufacturing

Sciaky Delivering World’s Largest Metal EB DED 3D Printer

Contract calls for a customized, high-deposition EBAM 300 Series additive manufacturing system to Turkish Aerospace Industries to 3D print titanium aerostructures 6 meters (nearly 20 feet) in length.

Read MoreThe Way Ahead for Wire Arc Additive Manufacturing

Tooling today, production tomorrow. The capability will advance as value is increasingly seen in lead time savings and design opportunities. Parts that today are cast offer a particularly promising application for a process that is “welding, except not.”

Read MoreSiemens, Gefertec Collaborate on Additive Manufacturing Software

Siemens’ NX software now supports operations for Wire Arc Additive Manufacturing (WAAM) printing technology.

Read MoreThermoplastic Composites Facilitate DED of Electric Scooter

The Scotsman scooter’s creators say it is the first fully custom, 3D printed electric scooter. The company uses Arevo’s Aqua DED system to print the carbon-fiber thermoplastic composite body.

Read MoreDirected Energy Deposition (DED) Error Turns Nozzle Into Chess Piece — AM: Why the Failure? #3

Chess pieces are often 3D printed as demo parts, but this one was an accident! What happened? The answer involves heat transfer.

Read MoreESPRIT CAM, Alma CAM Partner for Robot Additive DED Programming

Collaboration to provide customers with an end-to-end solution for robot programming, simulation, verification, collision detection, code generation and more.

Read More