Binder Jet

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

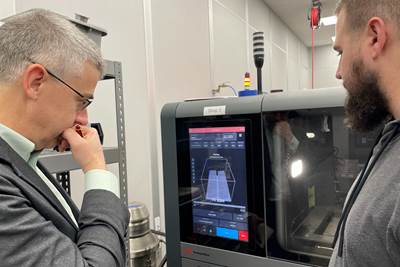

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

WatchChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreSinter-Based Additive Manufacturing Finds a Place Alongside MIM, Press and Sinter at APG

Powder metallurgy company Alpha Precision Group (APG) is applying a particular class of metal 3D printing technology for both rapid iteration in development and flexibility in production.

Read MoreHP and Elnik Team Up to Expand HP’s Sintering Expertise

HP asked Elnik Systems to develop a furnace configuration dedicated to processing metal additive manufactured parts, which are the cornerstone of its metal jet system development.

Read MoreHP Partners With INDO-MIM to Expand Metal Additive Manufacturing

Formnext: INDO-MIM has initially invested in three HP Metal Jet S100 printers as part of this collaboration and is in the process of becoming a certified partner of HP’s Digital Manufacturing Network (DMN) of leading manufacturers serving international markets across the globe.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

WatchMultimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreVideo: Multimodal Powders for Metal 3D Printing

Rather than uniform particle diameters, multimodal powders combine particles of different sizes. In this video, how and why Uniformity Labs produces multimodal metal powders for additive manufacturing.

WatchAMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

Read More

.png;maxWidth=300;quality=90)