Metal

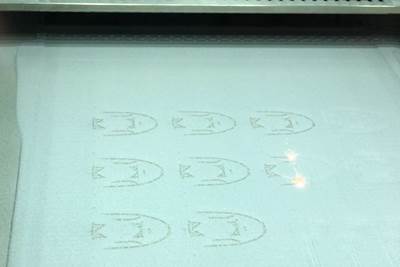

Additive Manufacturing Versus Cavitation

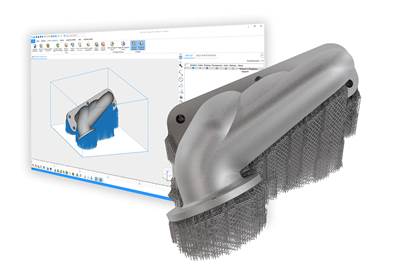

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

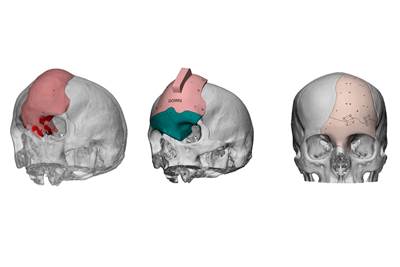

WatchArcomedLab Utilizes Biomedical 3D Printing for 700 Successful Craniomaxilofacial Implants in Latin America

The company specializes in biomedical 3D printing with a focus on patient-centric solutions.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreAccufacture Develops Alchemist 1 Robotic AM Cell Engineered With Meltio’s Wire-Laser Metal 3D printing Technology

This all-in-one additive manufacturing robotic work cell was engineered for seamless integration and rapid deployment for the safe and reliable manufacture and repair of metal parts.

Read MoreSpring 2024 TRX Showcases Projects Designed to Drive Additive Manufacturing Advancement

The America Makes TRX platform promotes exploration with more than 30 highlighted projects that are designed to propel the additive manufacturing industry.

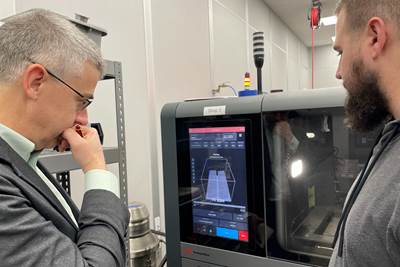

Read MoreVelo3D’s Flow Developer Enhancement Simplifies Parameter Development Process

The Developer enhancement in Velo3D’s Flow print preparation software gives users the freedom to migrate their own 3D printing parameters, even if developed on other brand machines, to a Velo3D Sapphire system where they can take advantage of machine-to-machine repeatability for series production.

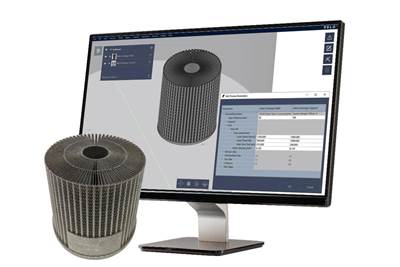

Read MoreMaterialise and Renishaw Integrate Systems to Improve Efficiency of Metal 3D Printing

Renishaw system users can now benefit from Materialise’s build processor software as well as its Magics data and build preparation software.

Read MoreVideo: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

WatchNikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Read MoreSintavia Plans $25 Million Expansion in Hollywood, Florida

The investments in facilities and equipment will power company’s growth over the coming years, including being able able to meet the demand from the programs it supports for the U.S. Department of Defense.

Read More

.png;maxWidth=300;quality=90)