Video: Smith & Nephew on 3D Printing Patient-Specific Surgical Instruments

Using MRI and additive manufacturing to produce a cutting block customized to the patient aids the precision of the surgery.

Medical device maker Smith & Nephew is using MRI measurements of knee-replacement patients in conjunction with 3D printing to make a “cutting block” that is tailored to the precise dimensions of the patient. The custom instrument aids the precision and efficiency of a surgical procedure that is becoming increasingly common. Smith & Nephew’s Mark Morrison discussed this custom surgical tooling in a conversation we filmed at the Additive Manufacturing Conference.

Transcript:

Peter Zelinski, Additive Manufacturing

I'm Pete Zelinski with Additive Manufacturing magazine. And I am here with Dr. Mark Morrison, who is manager of research and tribology with Smith & Nephew. Mark, Smith & Nephew is using 3D printing to make instruments that reduce the time and trauma of surgical procedures many of us are very familiar with. What is the surgical procedure and describe the instrument.

Mark Morrison, Smith & Nephew

So, we have these patient-specific instruments for total knee arthroplasty or knee replacement, and so we take imaging from the patient before surgery. We construct a model of their bone, then we create a patient-specific additive-manufactured cutting block or instrument, essentially, that we print and ship to the hospital for the surgery and the surgeon uses that. It fits like a glove, basically, on the patient's bone, and helps a surgeon precisely place cuts. And, better, be more efficient in the OR with that surgery and hopefully more precise in the implantation of that device.

Peter Zelinski

Custom fit to the patient. Can you describe that process? How is the patient measured and how does that result in a customized tool?

Mark Morrison

Right, so we use…. At Smith & Nephew, we use MRI imaging of that patient, and so MRI takes high-resolution images of anatomy in slices, so we segment those slices to segment bone and everything else. We take those slices of bone and create a 3D model of that patient's bone and then we can do many iterations of planning the surgery. We can tweak the surgical plan and see what works best for this patient. We propose that plan to the surgeon. And ultimately, he signs off on what he's happy with and then we use that model and that surgical plan to design this patient-specific instrument.

Peter Zelinski

So, you use the word “instrument.” Our audience—manufacturers—would think of it as tooling. You're creating tooling that is geometrically customized to the patient. And I wonder if you could talk to me about that from the patient's perspective. Why is it so valuable to have patient-matched instrumentation?

Mark Morrison

The placement of that implant in the body relative to the patient's anatomy is very important to the performance of that joint. With the patient-specific instrument we can better control that. We can help the surgeon plan, number one, and two, better implant it in the right place and hopefully provide better longevity of that implant for that patient.

Peter Zelinski

What is the material the instrument is made out of and what machine do you produce it on?

Mark Morrison

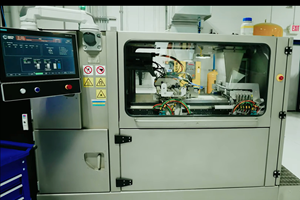

We're using an EOS 3D printer or additive manufacturing system and we're printing those devices out of nylon.

Peter Zelinski

All right, so we've been talking about tooling for surgery, customized instruments. Smith & Nephew uses additive also to make implants. Can you talk about that?

Mark Morrison

Yeah, so at the beginning of 2016 we launched our first additive-manufactured implant. It’s an acetabular shell for a hip replacement and additive, what that's allowed us to do in that space is to create our own proprietary porous structure. Additive provides the opportunity to custom-design what that surface feels like and looks like and how it grabs onto the bone and holds that device in place.

Related Content

From Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read More3D Printing Startup to Deliver Thousands of Custom Hearing Aids Over Next Five Years

Starting with a pilot program in Jordan, nonprofit 3DP4ME is developing workflows to 3D print hearing aid earmolds and prosthetics near the people who need them.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreRead Next

3D-Printed Metal Device Makes ACL Knee Surgery More Accurate

Additive manufacturing made it possible to produce a medical tool that offers surgeons better control during ACL repair or replacement surgery.

Read More3D-Printed Medical Drills Keep Bone Cool During Surgery

Drills made via additive manufacturing cut bones without causing thermal-induced damage thanks to internal cooling channels.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)