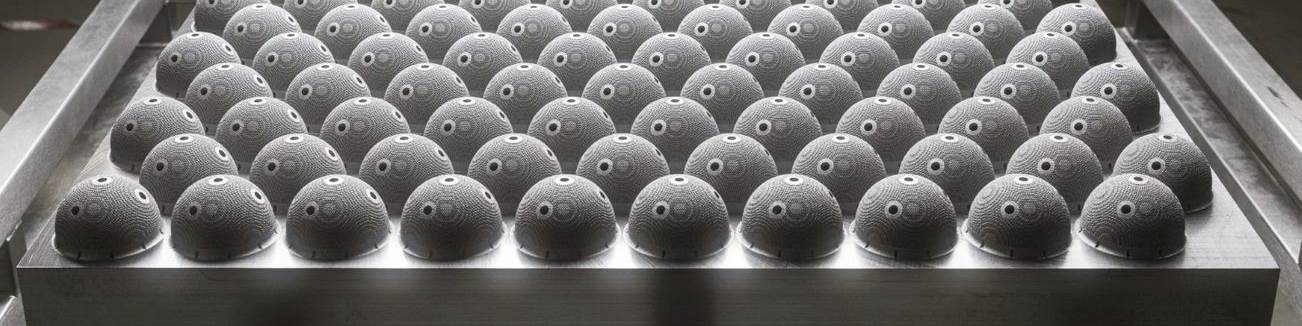

VulcanForms’ Devens, Massachusetts, facility serves as both the factory for assembling its high-throughput laser powder bed fusion 3D printers as well as a fully integrated manufacturing facility using those same machines. There are currently 15 proprietary printers already in use at this location. Photo Credit: VulcanForms

Founded in 2015 by Martin Feldmann and MIT professor John Hart, VulcanForms has become something of a poster child for the promise of highly productive metal 3D printing. With four facilities around the Boston, Massachusetts, area and a collection of its own proprietary laser powder bed fusion (LPBF) machines online already with more on the way, the company certainly looks like an additive manufacturing innovator from the outside. But after spending some time talking with Feldmann and Hart at the company’s Devens facility this March, it became clear that there was quite a bit more going on than 3D printer production and usage.

“We approach production less from a technology perspective and more from an economic perspective,” Feldmann says. “Our core competency is actually value optimization.”

For VulcanForms, value is achieved through a combination of its own proprietary hardware, cost modeling competency, and optimization of everything from feedstock through supply chain. And pursuing value on behalf of customers means looking at more than additive manufacturing for production.

“We’re looking at the technical and economic feasibility of all processes, not just additive,” Hart says.

What VulcanForms is working toward is a streamlined model of fully integrated manufacturing enabled by digital processes. The aim is a large-scale production model in which the variables are so well understood that pricing becomes second nature and accepting a purchase order becomes as easy as dragging and dropping workflow steps like virtual building blocks on a screen. Additive manufacturing is and will continue to be a key production option, but it is not the only consideration. VulcanForms’ recently established fourth facility is actually a machine shop that the company acquired in 2022. While much of the reason was to keep up with AM’s postprocessing demands, the machining capacity is also a potential manufacturing choice, and VulcanForms is investing in sophisticated, highly automated cells that combine machining with inspection and other processes where this method of manufacturing makes sense.

Located in Newburyport, Masschussetts, VulcanForms’ most recent acquisition is a machine shop now dedicated to postprocessing of additive parts, as well as manufacturing components outright. The link between 3D printing and CNC machining is digitization — which allows for automation in both cases. Photo Credit: VulcanForms

Despite their divergent methods of part production, additive and subtractive manufacturing at VulcanForms are unified in their digitization. “A line of code can change what parts the machines make,” Feldmann says. “That’s true for additive and for CNC machining.” Other processes like casting and forging will not be part of VulcanForms’ future, he says, because these processes are inherently analog in their need for hard tooling.

High-Productivity Laser Powder Bed Fusion

All that being said, VulcanForms is more an additive manufacturing company than it is a machining company. The business was founded on the premise that laser powder bed fusion has a place in high-volume metal parts production, but that the technology was not on track to reach its potential.

“No one had put all the pieces together,” Hart says.

Martin Feldmann (left) is VulcanForms president and CEO. Feldmann cofounded the company with John Hart (right). The two met in 2013 at MIT. Photo Credit: VulcanForms

The company’s two founders met at MIT in 2013, when Feldmann was a master’s student and Hart was beginning his professorship at the institution. Feldmann worked in Hart’s lab (though not on additive research) and the two eventually began to develop the technology that would become the 3D printing platform for VulcanForms.

The company’s laser powder bed fusion 3D printers promise exponentially greater productivity primarily achieved through higher power and more lasers, applied across a 600 by 600-mm build plate. At least in the second generation of the machines that I saw during my visit, the print head (which moves over the surface of the plate during the build) features an array of 147 infrared lasers. The 100-kW-class machines are driven by a complex and proprietary laser-optical control system, which the company says enables consistent material properties while performing LPBF at scale.

Currently there are 15 VulcanForms 3D printers in use in Devens, with more capacity located at other facilities. Third-generation machines are currently being built at the Devens site as well.

“Most frequently, we are scaling production of parts that were previously developed on conventional LPBF systems...”

But the company is already finding success with using the existing printers, primarily for additive manufacturing in titanium. “Most frequently, we are scaling production of parts that were previously developed on conventional LPBF systems, which were unable to achieve the quality and/or production volumes needed by our customers,” Feldmann says. Even for these parts developed with AM in mind, VulcanForms is finding that the speed and size of its machines can bring advantages in terms of performance and cost.

Value Optimization as a Core Competency

The ability to both optimize and demonstrate value (including potential cost savings) has been an asset to VulcanForms’ success so far. Whenever a new opportunity comes in, cost modeling methodologies are applied to ensure parts will meet their target price point. For now this is a somewhat manual calculation process, but the company is working on in-house software to further automate this step. Then, it is the job of the Advanced Production Technologies team to design the appropriate workflow, which might include everything from additive manufacturing to heat treat to machining, to one day passivation and surface engineering.

For parts that will be made additively, in-house software is used to derive a “thermal prescription” that dictates tool paths in the printer. Cameras and sensors on the printers themselves collect data that VulcanForms uses to create a digital twin and improve its models over time.

The productivity of the VulcanForms 3D printing technology comes from the use of a 147-laser array which moves across the 600 × 600-mm build plate. The high-power machines deliver parts quickly and at costs low enough to compete with conventional processes is many cases. Photo Credit: VulcanForms

Software development aimed at simulating and improving the manufacturing process directly is coupled with more enterprise-focused efforts. Shane McCauliffe, who served as a Pratt & Whitney PC&L associate director prior to joining VulcanForms, has been a valuable hire in integrating Epicor as the company’s ERP system, Feldmann says, and helping the company connect directly with large OEM customers. Applying a company-wide MES system will follow.

Workforce skill and hiring trends have played an important role in VulcanForms’ growth alongside software and hardware. Feldmann cites the company’s habit of hiring for fundamental business skills rather than additive knowledge as a particular strength, for instance bringing in aviation experts to manage its aerospace vertical and operations professionals who may not necessarily have AM experience. More than 300 people currently work across the company’s four facilities.

Laser Focused, Future Bound

For now Feldman says the company is “maniacally focused” on just a few qualification and production programs in a select group of verticals: aerospace & defense, orthopedics, and technology. Its Devens facility is ISO 9001, ISO 13485 and AS 9001D certified, in addition to being ITAR compliant. These fields are places where VulcanForms can already win on value, and where its other aim aligns: producing mission critical, nondiscretionary products in the United States. (Compared to “discretionary” items like, say, bike parts where stopping production might have little to no consequence.)

For now, VulcanForms is focused on serving just a few key industries and applying its 3D printing technology where additive adds value — like for these acetabular hip cups and other orthopedic implants. In the future, the contract manufacturer anticipates more applications where AM is the only option. Photo Credit: VulcanForms

Parts in production now aren’t drastically different from other LPBF parts. Acetabular cups, for instance, are a well-known additive application where VulcanForms’ solution excels. But that will change, says VulcanForms, which plans to serve other markets as well with fast and affordable parts. Indeed, accelerating product innovation in partnership with customers is one of the company’s core activities already, alongside large-scale production.

“Additive manufacturing will have reached the mainstream when it is embedded in product development,” Hart says. “More additive-enabled products are coming.” Rather than a (potentially) cost-effective alternative to other manufacturing methods, AM will become a necessary production mode for these new products — think heat exchangers, EV motor components, rocket engines with advanced cooling.

“The next generation of engineers will approach problems from the additive manufacturing perspective,” Feldmann adds. “The highest value applications for AM and digital technology have not yet been found.”

Related Content

AM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

Read MoreHow Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreAM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreRead Next

Productivity Gains Set to Transform AM

Integrated digital production set to transform additive manufacturing.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)