Articles

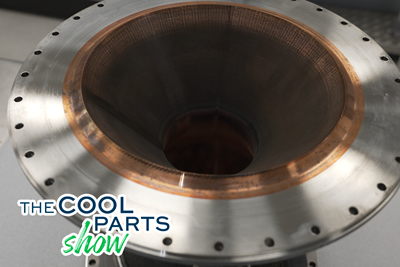

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multi-metal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

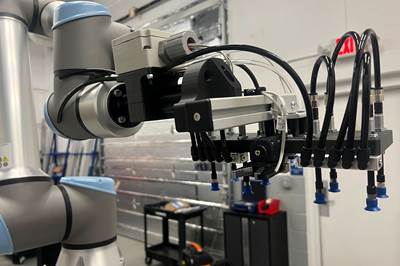

WatchRobotics Integrator Leverages 3D Printing for Faster Automation Deployment

Rapid Robotics helps manufacturers get up and running with automation quickly, by providing robots that arrive pretrained and already equipped with tooling which is often 3D printed.

Read MoreAdditive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

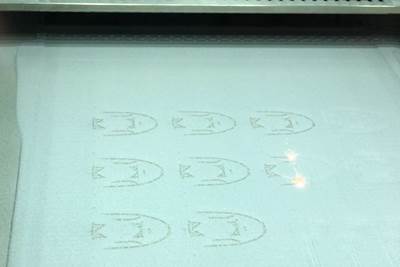

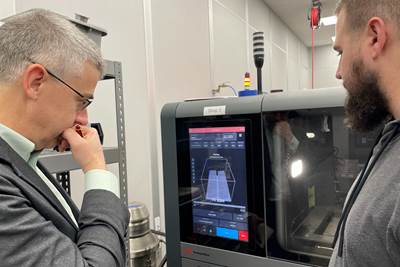

WatchHow to Rapidly Calibrate 4-Laser Production LPBF Machines

Multi-laser machines introduce an additional source of variation; the separate lasers have to synch with one another. At this Indiana additive manufacturer, one-third of the laser powder bed fusion machines are multi-laser. Here is is the AM calibration tool this company uses.

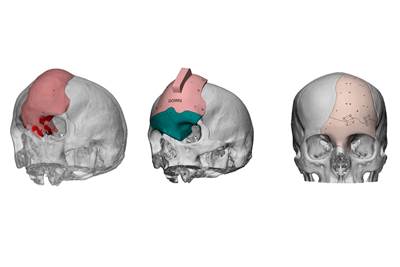

Read MoreArcomedLab Utilizes Biomedical 3D Printing for 700 Successful Craniomaxilofacial Implants in Latin America, and More News of Note

Accufacture develops Alchemist 1 Robotic AM cell engineered with Meltio’s wire-laser metal 3D printing technology | Formlabs’ Form 4 3D printer offers new levels of reliability and speed for stereolithography

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

Watch3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

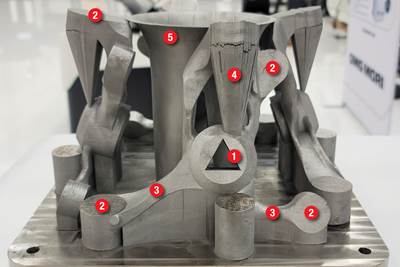

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreVideo: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

WatchThe Softer Side of Robots: Automating Additive Manufacturing

Robotic applications are expanding in additive manufacturing thanks to rubber and silicone-based systems that can easily adapt to parts of varying sizes and shapes without reprogramming.

Read More

.png;maxWidth=300;quality=90)