Prototyping

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

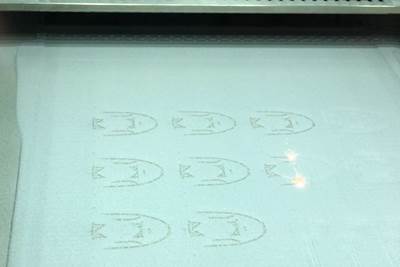

WatchHow to Rapidly Calibrate 4-Laser Production LPBF Machines

Multi-laser machines introduce an additional source of variation; the separate lasers have to synch with one another. At this Indiana additive manufacturer, one-third of the laser powder bed fusion machines are multi-laser. Here is is the AM calibration tool this company uses.

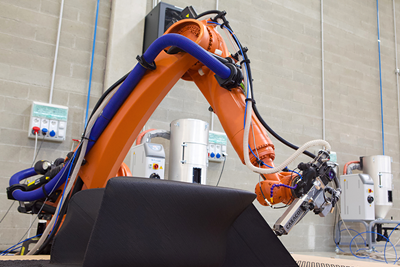

Read MoreCMS, Caracol Collaboration Targets Large-Format 3D Printing Market

Global development of LFAM technologies and applications will support end-user’s adoption of 3D printing for composites.

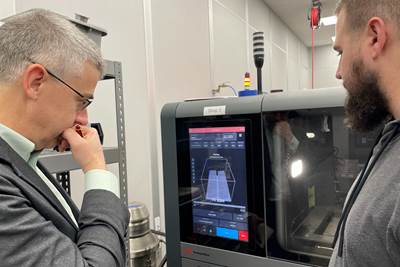

Read MoreFormlabs’ Form 4 3D Printer Offers New Levels of Reliability and Speed for Stereolithography

The Form 4 is designed to deliver most parts in less than two hours, offering users a powerful, affordable tool to bring ideas to life at fast speeds with excellent reliability, print quality and ease of use.

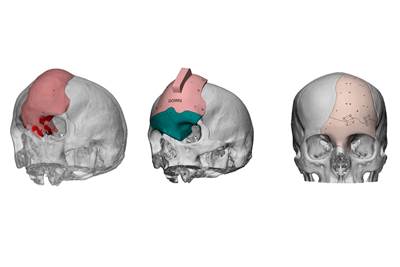

Read MoreArcomedLab Utilizes Biomedical 3D Printing for 700 Successful Craniomaxilofacial Implants in Latin America

The company specializes in biomedical 3D printing with a focus on patient-centric solutions.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

WatchAccufacture Develops Alchemist 1 Robotic AM Cell Engineered With Meltio’s Wire-Laser Metal 3D printing Technology

This all-in-one additive manufacturing robotic work cell was engineered for seamless integration and rapid deployment for the safe and reliable manufacture and repair of metal parts.

Read MoreFormnext 2024 Announces Call for Speakers

The proposals for papers can be submitted no later than June 30, 2024.

Read MoreSpring 2024 TRX Showcases Projects Designed to Drive Additive Manufacturing Advancement

The America Makes TRX platform promotes exploration with more than 30 highlighted projects that are designed to propel the additive manufacturing industry.

Read More

.png;maxWidth=300;quality=90)