Inspection & Measurement

Casting Goes Digital with Sand 3D Printing, Nondestructive Testing

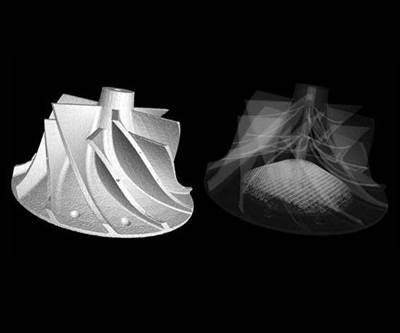

Tooling & Equipment International (TEI) used to make tooling for castings. Now, it casts prototype parts in a digital workflow using 3D printed sand molds in combination with simulation software, CT scanning and X-ray technology.

Read MoreThermo Fisher Scientific Desktop SEM Improves Quality Control and Material Cleanliness

Thermo Fisher Scientific has introduced the Thermo Scientific Phenom ParticleX, a desktop scanning electron microscope (SEM) solution.

Read MoreEvonik Develops Implant-Quality PEEK Filament for 3D Printing

Based on its Vestakeep i4 G, Evonik's 3D printing material offers biocompatibility, biostability and X-ray transparency.

Read MoreThermo Scientific Explorer 4 Characterizes Metal Powders

The Explorer 4 system uses scanning electron microscopy (SEM) to measure and characterize metal powders for 3D printing.

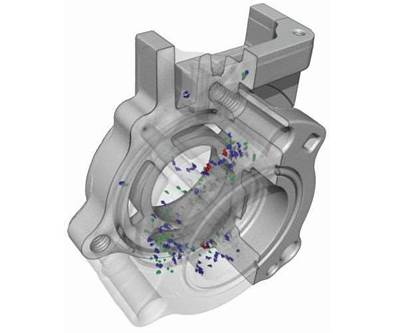

Read MoreYxlon Cheetah Evo Plus Enables Inspection of 3D-Printed Parts

Rapid 2018: The system supports both X-ray and CT inspection of additively manufactured parts.

Read MoreVerifying Structural Integrity of Metal 3D-Printed Parts

X-ray computed tomography, or micro CT, offers insight into the inside of AM parts.

Read MoreValidating and Qualifying

X-ray technology can validate the internal geometry of additively-manufactured parts in 3D without destroying the part.

Read More

.png;maxWidth=300;quality=90)