Senvol ML Enables New Approach for Material Allowables Development

Senvol demonstrates use of machine learning software to enable path for rapid development of material property allowables for additive manufacturing.

Share

Read Next

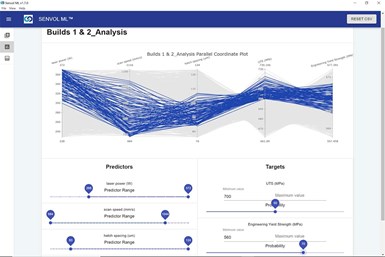

Senvol ML is a data-driven machine learning software to analyze relationships between additive manufacturing process parameters and material performance. Photo Credit: Senvol

Senvol recently demonstrated a machine learning approach to material property allowables development that the company says is more flexible, cost-effective and time-effective as well as just as accurate as the conventional approach (in this case, CMH-17) to allowables development.

The work was done as part of a contract awarded by America Makes, the national additive manufacturing institute, and funded by the U.S. Air Force, to apply its machine learning software, Senvol ML, to enable a path to rapid development of material property allowables for additive manufacturing (AM).

Senvol’s partners on the program included Northrop Grumman, the National Institute for Aviation Research (NIAR), Stratasys Direct Manufacturing and Pilgrim Consulting.

As part of the program, Senvol demonstrated a new approach to material property allowables development that leverages machine learning. The company says the machine learning approach is extremely flexible and able to handle any change to the AM process, which makes this approach well suited for sustainment in the long term. The program focused on demonstrating the approach using a Nylon 11 Flame Retardant material processed via a polymer powder bed fusion AM machine.

“Additive manufacturing is a modern and digital manufacturing method with rapidly tailorable processing. To continue to use traditional material allowables development approaches is a bottleneck to wider material and process options, and capabilities for additive manufacturing,” says Dr. Brandon Ribic, America Makes technology director. “Senvol’s program was very powerful in demonstrating an approach to additive manufacturing allowables that leverages the digital nature of the technology and leverages machine learning, a modern data analysis approach that has been shown to be extremely effective in a multitude of other industries.”

AM is starting to enable lightweight and rapidly produced designs that are revolutionary to various U.S. Air Force and commercial capabilities and applications. It is said these benefits cannot yet be fully realized due to the time and high cost of allowables development.

The high cost is said to stem, in large part, from the fact that material allowable development requires an enormous amount of empirical data to be generated, at a fixed processing point, meaning that all of the empirical data must typically be regenerated from scratch every time there is a major change in the process. This results in an AM process that is not only costly and time-consuming to implement the first time, but costly and time-consuming to maintain in the long-run when there are inevitably changes to the AM process.

The Senvol ML software supports the qualification of AM processes and was used in the program to develop statistically substantiated material properties analogous to material allowables. The company says it did so while simultaneously optimizing data generation requirements. It is said the software is flexible and can be applied to any AM process, AM machine and AM material.

“Senvol implemented data-driven machine learning technology that has the potential to substantially reduce the cost of material allowables development,” says Zach Simkin, Senvol president. “By demonstrating an entirely new – and significantly more efficient – approach to allowables development, Senvol aims to drive tremendous value for the U.S. Air Force, the America Makes membership and the additive manufacturing industry at large.”

Related Content

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreLightweight Components: A Paradox When Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreAdditive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)