5 Impressions of Additive Manufacturing at IMTS 2018

An emphasis on production, shifting target markets and more colored additive manufacturing’s presence at this year’s International Manufacturing Technology Show (IMTS).

The Additive Manufacturing Pavilion at the International Manufacturing Technology Show (IMTS) was established in 2016. Situated at the front of the North Building of Chicago’s McCormick Place, the pavilion housed twenty-some exhibitors and gave IMTS attendees a central location to survey current and emerging 3D printing technologies.

This past September, AM’s presence at IMTS was even greater, with the AM Pavilion moving to the West Building and increasing in size to more than 50 exhibitors. The feel of this space was different too; the AM Pavilion in 2018 was not a diversion from the rest of IMTS, but a destination in its own right. This shift was the result not solely of show design or planning, but of AM’s technological advance and of the growing role that 3D printing is playing across manufacturing.

During the show I noticed several trends that speak to AM’s advance, both in and out of this pavilion. The list below is by no means exhaustive, but serves to illustrate how far additive has come and to suggest where it might be going next:

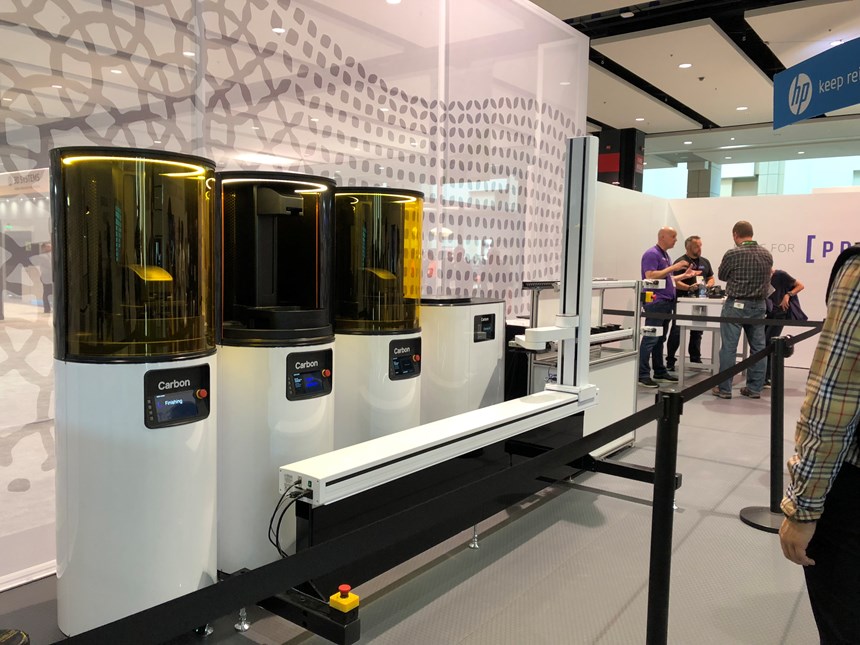

- Production emphasis. IMTS 2018 saw a number of product launches designed for high throughput, including technologies like HP’s Metal Jet 3D printer for volume production of metal parts. AM systems that integrate material handling and postprocessing such were also prevalent, as was automation integration. Carbon’s booth, for instance, equipped a line of three M2 printers and a parts washer with an automated tending system to demonstrate how such a line could be run unattended.

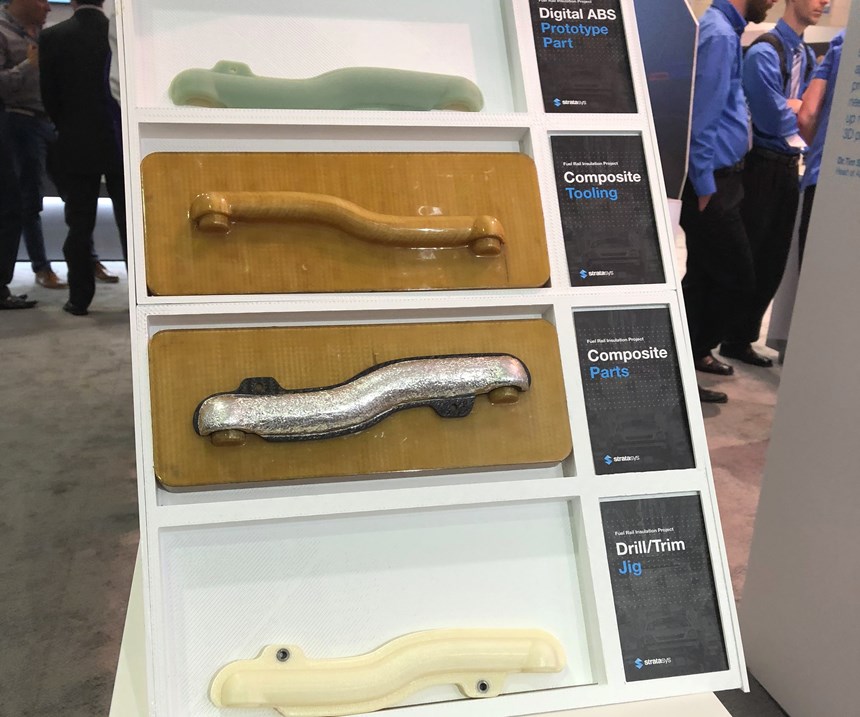

- Automotive as an end market. While aerospace and medical have been standby markets for 3D printing, more and more companies appear to be targeting the automotive industry. Machine launches emphasized conventional automotive materials like steel, and car parts were a common site in exhibitor booths this year. One example in the slideshow above shows a VW rocker arm made by Fathom via Desktop Metal’s Studio System. HP’s Metal Jet launch was even accompanied by commentary from Volkswagen on metal 3D printing’s potential to manufacture lighter, stronger and more functional car parts. But metals weren’t the only focus. A Penske racecar on display in the Stratasys booth helped the company make the point that its printers and polymer materials are used in automotive applications including prototyping, tooling and functional parts.

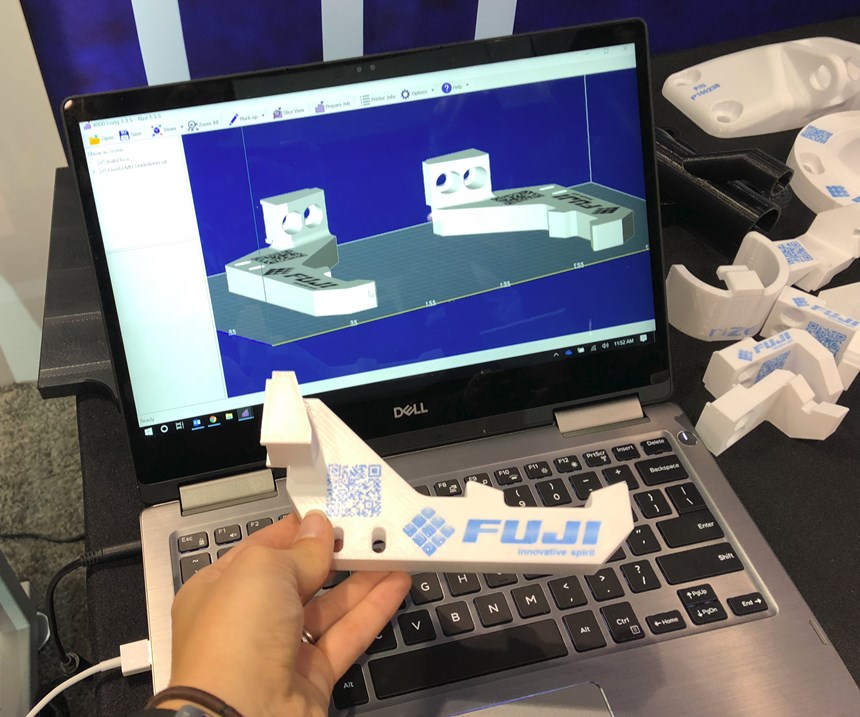

- Software of all kinds. Generative design and topology optimization software are natural companions to additive manufacturing, the technology perhaps best-suited to manufacturing the organic, latticed structures these programs can create. But AM suppliers also emphasized software of other types, like that for process simulation, order management and fleet control. Desktop Metal for instance showcased its Live Parts generative design tool alongside Fab Flow, a customizable workflow tool for design verification and order management designed for use by internal model shops. Carbon highlighted its fleet management software, which governs part files, hardware and materials but also monitors print parameters. The software can actually enable faster prints on the same hardware over time, as it “learns” from accumulated builds.

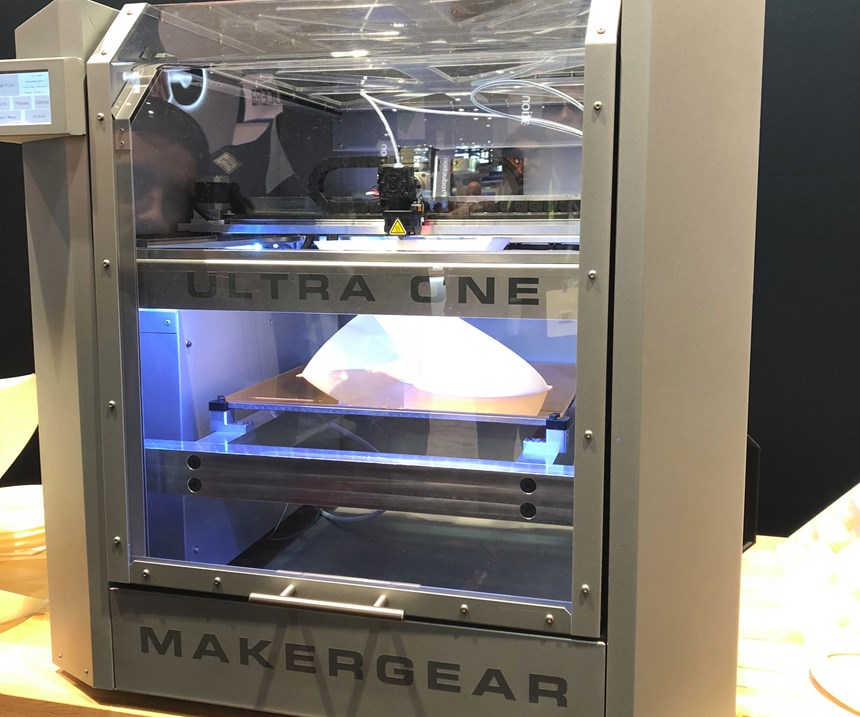

- A spotlight on 3D printer components. As users are expecting more and more out of their machines, suppliers are giving more prominence to the capability and quality of individual components. In some cases this meant highlighting 3D printer parts that were themselves 3D printed; in others the conversation turned to enclosures, frames and motion control elements such as linear rails. Titan Robotics, for instance, opted to showcase a custom Atlas 3D printer in the Yaskawa America booth, highlighting the Yaskawa servo-controlled drives inside this machine. Suppliers are beginning to talk about their equipment more like machine tool providers, pointing out the advantages that these features can provide for users or offering customization at the component level.

- Maturing market. This last point is somewhat anecdotal, but many exhibitors commented on the knowledge level of attendees coming through the AM Pavilion or seeking out other 3D printing. Booth visitors were better informed about 3D printing technologies than in years past, and more willing to buy. There also seemed to be maturation on the supplier side, with exhibitors expressing very clear ideas about the markets and industries their products are best-suited to serve, and for what applications.

Related Content

Multimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreRead Next

Stratasys Reflects on Where 3D Printing Is in 2018

Two years ago, Stratasys was looking forward to where 3D printing might be going. Now, it’s worth evaluating the current state of additive manufacturing with polymers.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)