We have covered the potential for additive manufacturing (AM) to change production processes and part designs. What about the business model?

This possibility—a different model for delivering parts, based on AM—is one that Production Services Management Inc. (PSMI) has seen. Adding 3D printing capability to existing installations by means of its newly created “Azoth” business unit will allow PSMI to give existing customers access to 3D printing essentially for free.

The idea shines a new light on the question of whether additive manufacturing is most effectively performed by current conventional manufacturers or by separate suppliers. Azoth is pointing the way toward a third option: a separate supplier resident within a conventional manufacturer.

Founded in 2005, PSMI is a company that operates and manages tool cribs and MRO supply cribs for manufacturing customers. Depending on the customer’s size, from one to 50 PSMI employees might work inside of a customer’s plant to provide manufacturing hardware such as tooling, spare parts and other supplies as needed. PSMI optimizes this part of the manufacturer’s operations by monitoring usage to both control inventory and seek the most cost-effective sources for needed components. Adding 3D printing elevates this model into something altogether different, by providing PSMI with the option to not just order a hardware component for a customer, but instead generate that part on-site right before the customer’s eyes.

Scott Burk is co-president of both PSMI and the new sister company Azoth. “Using 3D printing this way is going to let us add more value for our customers and become more valuable to them,” he says. “Right now, someone comes to one of our cribs wanting something, and we have to begin the ordering process.” 3D printing can in many cases offer a better way. It provides not only the potential to deliver the item more quickly, but also the chance to work with the customer on-site to optimize the design of what might be a specialty or custom component. The manufacturer’s entire sense of the role of a supply crib and what kind of service the crib can provide might change.

Ultimately, every PSMI crib could have access to 3D printing, says Burk, but only some cribs are large enough that they will justify having a 3D printer operating on site. Today, Azoth is testing the new model with a small number of customers doing business with PSMI at a scale large enough to justify one or two on-site machines.

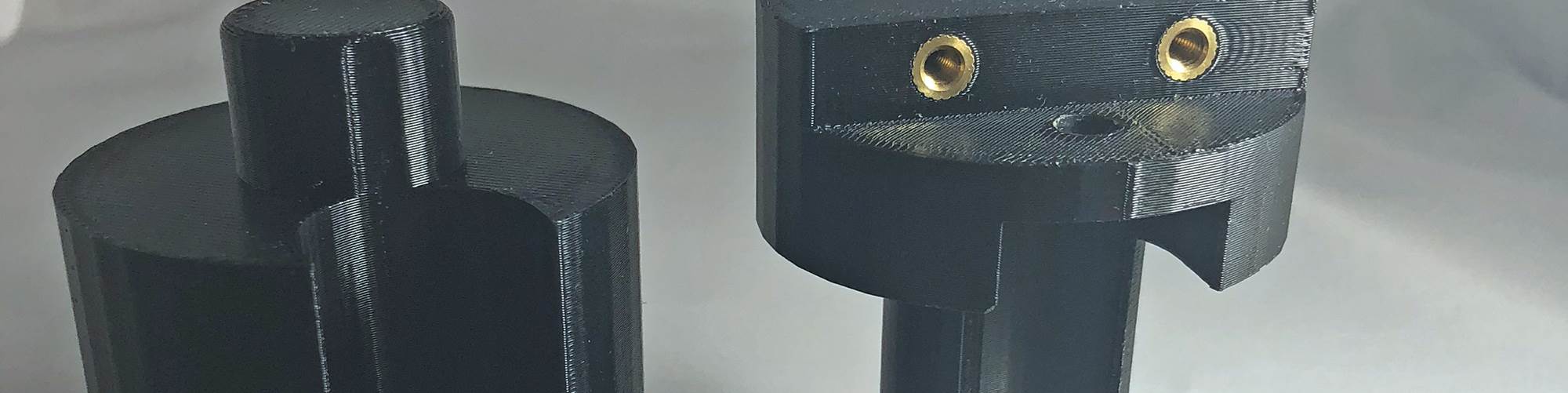

The 3D printer Azoth has chosen comes from Rize. Burk says safety and simplicity are two of the factors that drove this choice. Several points make Rize’s 3D printers distinctive, including the following:

- Tandem process. Rize’s process for building polymer parts uses extrusion and material jetting in tandem. The result is a part with isotropic strength, meaning no change in strength along the direction of 3D-printed layer lines, so part performance is not affected by orientation during printing.

- Automatic support generation. Users make simple choices such as “solid” or “infill,” but otherwise leave the printer to automatically add supports to the model.

- Operator-assist features. A magnetic build plate ensures accurate and secure loading within the machine. Automatic checks for consumables ensure enough remaining material and ink to finish the job selected.

- Safe operation. Designed to be “office safe,” the Rize system emits no volatile organic compounds (VOCs). A special ink the printer uses between the part and support structures ensures supports can be easily removed by hand, meaning no sharp tools or hazardous solvents are required for this removal.

The safety of the machines is important because PSMI deals with so many different manufacturers. It therefore needed a printer that could easily win approval for installation within the sites of many different established large companies. Meanwhile, the printers’ simplicity is important for the scalability of the business model. PSMI will begin to adapt the training of its personnel to include additive manufacturing, but even so, a complicated printer would limit how widely it can spread this idea because of the mastery needed to run each machine.

Spreading the idea widely might prove important. Burk sees wide-open possibilities for this model of on-site additive service, though he admits some of the possibilities might yet be far off. For example, one test customer for the additive capability was already using 3D printing for its own prototyping before Azoth was created, but that company lacked sufficient capacity to meet its prototyping demand. Now, PSMI/Azoth will be given the chance to make prototypes, even though this is not a type of part typically ordered from the supply crib. And if prototype parts can be sourced in this way, why not short-run production?

“To some extent, we need to wait for additive manufacturing technology to catch up to realize all the possibility we envision,” Burk says. For example, he does not yet see any of existing metal 3D printing solutions providing the kind of safe and simple deployability the Rize machines offer for polymer parts. “But when we can do this kind of printing in metal, say in H13, then that will let us give customers a whole new range of options,” he says. Azoth could serve as an efficient AM production resource right inside the plant. To get ready for that day, PSMI needs to show its customers they can begin to think differently about the role a tool crib might play.Related Content

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More