Articles

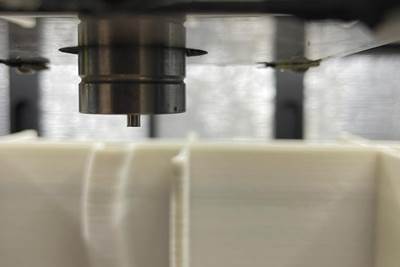

Mold 3D Printing Helps Automate Composite Bathtub, Shower Production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreEaton Developing Carbon-Reinforced PEKK to Replace Aluminum in Aircraft Air Ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreSinter-Based Additive Manufacturing Finds a Place Alongside MIM, Press and Sinter at APG

Powder metallurgy company Alpha Precision Group (APG) is applying a particular class of metal 3D printing technology for both rapid iteration in development and flexibility in production.

Read More5 Things You Get With Your Additive Manufacturing Subscription

A subscription to Additive Manufacturing is available to you at no cost. Here are five benefits of starting (or renewing) your Additive Manufacturing subscription.

WatchVideo: MoldJet Sinter-Based Additive Manufacturing at Alpha Precision Group

Alpha Precision Group (APG) in Ridgway, Pennsylvania, applies a range of sinter-based AM processes to produce metal parts. This video explores the MoldJet process from Tritone Technologies.

ListenThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.

Read More7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.

Read MoreHow a DOD-Funded Resilient Manufacturing Ecosystem (RME) Is Coming Together at Neighborhood 91

Pittsburgh’s additive manufacturing campus doubles as a test bed for a Department of Defense project aimed at developing a reproducible ecosystem for on-demand production of critical parts.

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

WatchHow Manufacturing Information Becomes "Golden": The Cool Parts Show All Access

Baker Hughes saves optimized production information in its PLM system for reuse later, creating “Golden Master” manufacturing routers. Rohan Buntval, additive manufacturing design engineer, goes into greater detail about how files become golden.

Watch

.png;maxWidth=300;quality=90)