Teton’s SmartSlice Reduces 3D Material Usage

Software can automatically optimize parameters so users can identify settings that yield the fastest print job by minimizing time and material while meeting strength requirements.

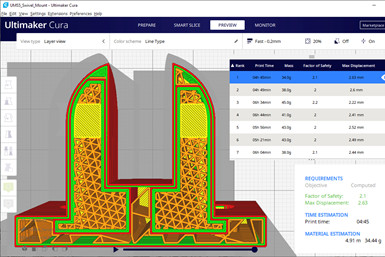

Teton Simulation’s SmartSlice software

Teton Simulation’s SmartSlice brings engineering-grade part simulation to Cura as a plug-in for Ultimaker Essentials users. Smart Slice is designed to reduce print times and material usage by optimizing print settings to ensure parts meets end-use requirements before parts are printed.

SmartSlice software creates the iterations virtually. Using the integration options of Cura’s open and pluggable platform, SmartSlice ensures that parts meet engineering criteria before printing, saving time and materials. Smart Slice is also well suited for replacing broken components to accelerate tool replacement, helping to get production back up and running quickly.

The company says that SmartSlice is easy to use and is extremely fast. It enables manufacturing engineers or machine operators to quickly iterate using the software rather than print unnecessary, wasted parts. Additionally, SmartSlice can automatically optimize parameters so users can identify settings that yield the fastest print job by minimizing time and material while meeting strength requirements. The technology also gives 3D printer operators near instant feedback on the viability of projects. Plus, the optimization feature takes the guesswork out of determining the right slicing parameters.

Related Content

-

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

-

Drones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

.png;maxWidth=300;quality=90)