Understanding the Health Impact of 3D Printers: A Q&A with UL

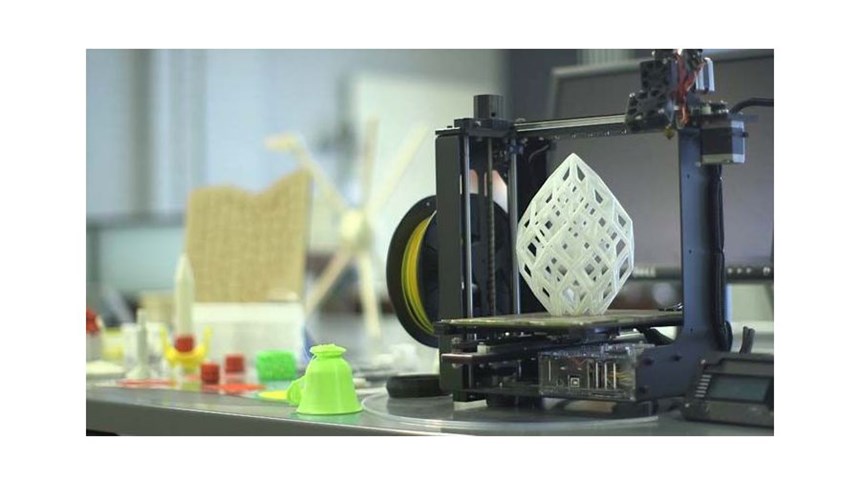

Dr. Marilyn Black, UL VP and senior technical advisor, discusses ongoing research on the impact of 3D printers on indoor air quality.

Share

As a follow-up to our Changing the Rules feature with UL, which brought safety to the forefront of the AM discussion, Additive Manufacturing magazine sat down with UL’s vice president and senior technical advisor Dr. Marilyn Black to find out what they have in store next. It turns out they have partnered with Georgia Tech and Emory University to research the impact of 3D printing on indoor air quality in two phases. Phase I will involve the characterization and assessment of particle and chemical emissions from 3D printing technologies and Phase II will assess potential health hazards from exposure to the emissions.

Here is what Dr. Black had to say about the need to understand the health impact of 3D printers and details about the research.

AM: Why the focus on the impact of 3D printing on indoor air quality?

UL: Because very little scientific research has been conducted to date, a knowledge gap exists in the understanding of the health implications associated with the emissions resulting from 3D printing technologies. While some preliminary information indicates that they might be harmful to human health, basic science has yet to define exactly what these emissions are and how to accurately measure them and assess their risks. Therefore, UL has stepped up to take a technical role and scientific lead to develop methodologies that will allow accurate and comparative characterization of the emissions among different machines, and the environments in which they are placed.

AM: Why did UL decide to partner with Georgia Tech and Emory University?

UL: The Georgia Institute of Technology’s Direct Digital Manufacturing Center is heavily involved with conducting AM research, and the School of Earth and Atmospheric Sciences is internationally renowned for its programs and research in the measurement of atmospheric pollution and human exposure. Georgia Tech has all the sophisticated measurement equipment and experts required for the study of ultrafine particle aerosols. Emory University’s Rollins School of Public Health also has a strong reputation and credibility in public health and risk assessment, making them a natural choice for the second phase. UL reached out specifically to these schools because of their national and international reputations in AM, atmospheric aerosol chemistry and environmental health risks.

AM: How will Phase I be conducted?

UL: Phase I began in early 2015 with an anticipated completion date of early 2016. Both phases of the research are to be completed by the end of 2016. Within Phase I we are looking to characterize the different emissions produced by 3D printers with a particular interest in ultrafine particle and volatile organic chemical (VOC) generation. These emissions will be monitored in relation to print time, print temperature and print media using specialized aerosol chemistry techniques. State-of-the-art toxicity studies of particles released during printing along with adsorbed chemicals on these particles will be performed, as they have the potential to be inhaled deeply into the lungs. Ultrafine particle exposure may be linked to health concerns including respiratory and cardiovascular disease. This research will allow us to assess the impact on the quality of indoor air and potential health hazards to those exposed, both consumers and workers.

Initial research is focused on smaller consumer and professional print hardware and media that are being used in homes, schools and offices and because of these environments do not have indoor air standards. Working with these machines in a laboratory is more practical, and also serves to address potential health hazards for more sensitive populations, such as children.

Once we have a standard methodology for evaluating emissions, we will seek to evaluate a range of different print technologies, so that we can understand the range of results expected. This will include larger machines and other print media, including metals. Initial materials used in the research will be simple print objects made by using fused deposition modeling (FDM) with various thermoplastics, including ABS, PLA and nylon.

Moving to more industrial applications with laser and metal processes will require additional method development and the ability to study them on-site because of the size of these machines. An initial objective of the current research is ensuring that an expandable methodology platform is established, so print variables can be monitored and control strategies can be evaluated.

AM: How will Phase II be conducted?

UL: Phase II will begin in a couple months with completion at the end of 2016. It will look at the data from a health perspective and evaluate the human health risk from exposure to the particles and chemicals. To do this, UL has partnered with Emory University, which has renowned expertise in environmental risk assessment. The data collected on particle and chemical emissions, specifically what they are and how much, will be reviewed with current toxicological risk models based on pulmonary exposure. In addition, some innovative toxicology studies will be made using human bioassays, where lung cells will be directly challenged with collected emissions from the print operations.

AM: How will the results be used, and what will you do with the results to better the industry?

UL: The research will benefit all manufacturers and stakeholders in the 3D printing industry. Although initial research is focused on consumer/desktop printing, the information gained, test methodologies and human risk evaluation processes used can be applied to different machines and their operating parameters. Risk models allow the application of emissions data to various environments and populations. Manufacturers can obtain knowledge of what the hazardous emissions are and how they are affected by the print parameters and media used. This information can help them manage their supply chain to reduce hazardous chemical content and engineer processes through equipment design to reduce hazardous emissions. Policymakers can be equipped with sound scientific information for evaluation of risk.

The information and knowledge gained from these studies can become part of UL’s safety curricula. The research will shed light on the potential health hazards, and what can be done to mitigate their impact on users and consumers. Potential health hazards can be learned as well as ways of mitigating their impact on users and consumers. As the research achieves certain milestones, UL will share the results with key stakeholders and manufacturers in an effort to educate and train the workforce on the established measurement and characterization of emissions from 3D printing technology under various situations. Future projects will lead to characterizing new technologies and print media with measurement and predictive modeling. In addition, research into metal and inorganic print media presents an ongoing opportunity.

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreAM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More