Fiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

Share

Composite parts built from layers of thermoplastics and reinforcing fibers offer a strong, lightweight solution for aerospace parts, surgical guides, consumer products and more. But when the composite material comes preconfigured as a sheet or roll, it actually becomes a hindrance to this promise.

“Textiles are very homogenous, so you have no freedom within the layers,” says Yannick Willemen. “If the material is 60% reinforcing content by volume, you will have 60% reinforcement everywhere even where it is not necessary. From a material efficiency point of view, we thought we could do better.”

Willemin is heading marketing and business development at 9T Labs, a spin-off from ETH Zurich, a university in Switzerland. Founded in 2018, the company has created a new way of building composite parts, one that combines 3D printing technique and filament with continuous carbon fiber reinforcement and compression molding to create strong, light components. The multi-step method delivers parts that can be both cheaper and less wasteful than either conventional composite or machined parts, with less porosity and more repeatability than other continuous carbon fiber 3D printing solutions can provide.

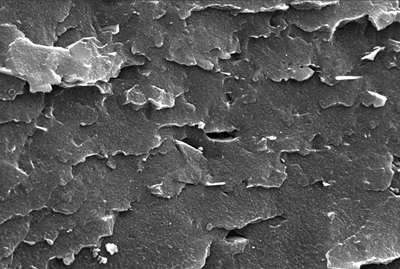

Rather than a consistent carbon fiber content throughout the part, 9T Lab’s process places the reinforcement only where needed, resulting in light yet strong parts. Image Credits: 9T Labs

Achieving Precise Fiber Control and High Density

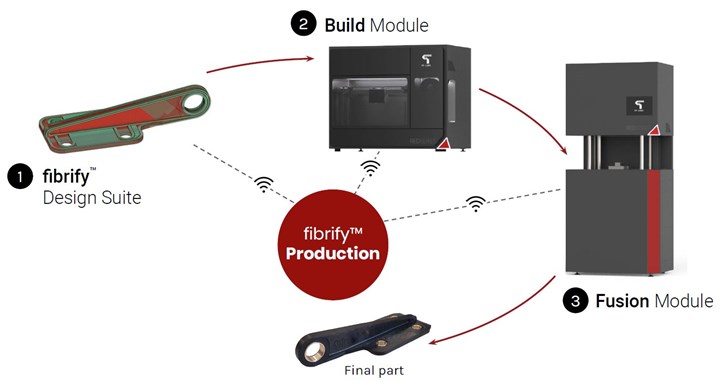

9T Labs’ Red Series system consists of its Fibrify software and two different machines, the Build module and the Fusion module. The Build module is essentially a 3D printer with two deposition nozzles to place thermoplastic filament (to date, mostly PA12 and PEKK) alongside carbon fiber-reinforced filament. The platform is open source, and customers are free to use whatever filament they wish with some adjustment to print parameters to maintain the proper temperatures. The carbon fiber is also off-the-shelf, but with some modification. 9T Labs sources carbon fiber tape and has it cut into 1-mm widths and respooled; this flat tape is fed into the Build module and is thermoformed into a round filament before being delivered to the print head in the build chamber.

Carbon fiber tape is fed into the Build module from the top, where it is thermoformed into round filament in the upper chamber before being extruded alongside thermoplastic onto the build plate.

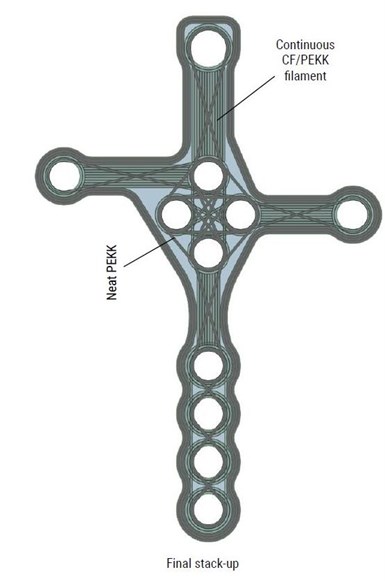

The printhead itself features two nozzles to apply the thermoplastic and carbon fiber filament in succession. Importantly, the reinforced filament need not follow the same path as the neat plastic; instead, this capability can be turned on and off as needed. The Fibrify software provides user-adjustable intelligent fiber layup suggestions and integrates with commercially available FEA simulation packages such as ANSYS to verify and optimize these patterns. “We want to place the least amount of fiber for the maximum performance requested,” Willemin says.

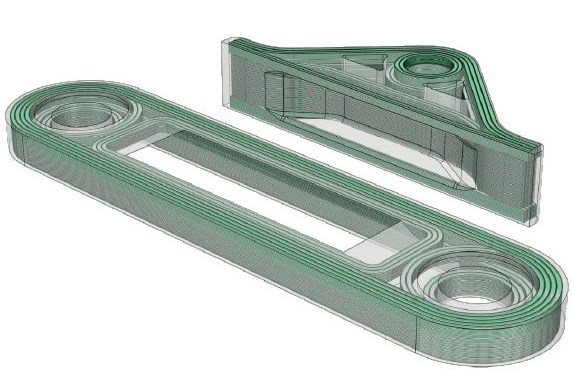

An example of optimized fiber placement in this aiming arm, a surgical guide for bone drilling.

Parts are usable right out of the printer as functional prototypes, jigs and fixtures, or one-off parts, but voids and dimensional accuracy preclude them from most of the high-performance production applications 9T Labs is truly after. To achieve their final density and dimensions, these “preform” parts go through a compression molding step in the Fusion module, capable of reaching temperatures up to 400°C and active pressure regulation of greater than 20 bar.

This step uses a mold tool unique to the part — typically machined aluminum for a short-run job, or stainless steel for higher volumes — to compress the printed layers and fiber together, resulting in a low-porosity, dense and strong final composite piece. Parts are said to achieve less than 1% void content through the Fusion process. As an added benefit, bushings, bearings and other inserts can be added to parts before compression molding and secured into place during this step, reducing assembly on the other side. The process also allows multiple sub-parts to be assembled and fused into one part with a complex fiber orientation.

The process for building a dense, low-void composite part includes both 3D printing and compression molding.

3D Printing and Tooling Together

A critic coming from an additive manufacturing (AM) perspective might point out that this process still relies on tooling, the expensive, time-consuming step that AM promises to remove for processes like injection molding. And indeed, the compression molding step does impose necessary limitations on 3D printing’s geometric freedoms. But tooling isn’t the challenge that 9T Labs is out to overcome; instead, the company wants to automate the preform process, because doing so will allow smaller scale composites (those that fit inside the system’s 350 × 270 × 250-mm volume) to more cost effectively compete with metalworking and “low-engineered composites” produced by machining blocks of material.

9T Labs’ process reduces labor as well as waste and mass over those conventional manufacturing methods. Compared to machined aluminum, Red Series composite parts are lighter weight and can be built without creating chips or scrap. And because the reinforcing fibers are placed only where needed, the parts are generally even lighter than conventional composites while still being strong enough to perform in use. Plus, they are far more cost-effective to make at small scale and quantity.

A feasibility study showed that this aerospace bracket could be produced 78% lighter and at 50% less cost compared to machined aerospace-grade steel. The horizontal and vertical components are 3D printed separately, flat against the build plate, and then consolidated during the Fusion step.

One potential area where 9T Labs can excel might be aerospace brackets, a niche currently dominated by machined aluminum. “It makes no sense economically to make them today from composites, because you would have to lay the material down manually in a very complex manner,” Willemin says. But with an automated process to 3D print the preform with precise structural control, a composites solution could be not only more affordable, but stronger and lighter — a boon to fuel efficiency as well.

Reinventing Fiber Content as a KPI

To date, 9T Labs has placed a handful of Red Series systems in the field, and maintains others at its facility for specific customers. The company sees its sweet spot as strong, lightweight parts needed in quantities ranging from 100 to 100,000 per year, and is already finding use cases in consumer products such as mountain bikes and watch casings; medical instruments such as aiming guides for bone drilling; and aerospace components such as hinges for helicopter doors.

This surgical aiming arm (reinforcement pictured above) can be made 11% lighter than conventional, 60% carbon composite and 48% lighter than machined aluminum alloy using the 9T Labs process.

Willemin is confident that there will be more. But expanding the applications for the Red Series technology will mean not only changing a manufacturing process, but also the key performance indicators (KPIs) by which parts are evaluated.

“A common KPI in composites is fiber content,” Willemin explains. “We [9T Labs] might say it’s 25%, and the assumption would be that the part cannot accept the load. But it’s 25% at some points, 0% at some points, and 75% at some points. 3D printing gives this level of granularity, but it also demands that we challenge and reinvent the KPIs.”

Related Content

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read MoreWhy “Boring” Is Superlative for Additive Manufacturing: AM Radio #29A

It is impressive to be the biggest, smallest, first, only, thinnest and more additively manufactured part. But there is value in the average or mundane parts, too. We discuss examples on this episode of AM Radio.

Read MoreRead Next

Video: 3D-Printed Composite Hooks Lifts Hundreds of Pounds

AM challenges expectations about which applications and part types call for metal and which are appropriate for polymer.

Read MoreThe Promise of Graphene-Based Composites for 3D Printing

A new partnership between XG Sciences and Terrafilum aims to accelerate industrial innovations using the strongest, thinnest, most electrically conductive material on Earth.

Read MoreReinforced Polymer 3D Printing, Adjustable on the Fly

With Continuous Kinetic Mixing (CKM), 3DFortify sees expanded possibilities for printing polymer composites reinforced with fibers, ceramics and even metal flake in any concentration needed.

Read More

.jpg;width=70;height=70;mode=crop)