Getting to a profitable part with additive manufacturing (AM) requires careful attention to a variety of factors that impact performance and drive cost. Among these many factors is the extent of postprocessing that must be done to the part after layer-wise fabrication ends.

postprocessing is rarely viewed in a favorable light. All too often it is treated as a “necessary evil” that adds cost and schedule to an otherwise already expensive manufacturing process.

For polymer 3D-printed parts, postprocessing can be as simple as dropping the part into a washing system to dissolve and remove unwanted support structures or using acetone vapor smoothing to help make the part watertight. Some polymer 3D-printed parts may require additional postprocessing to achieve tolerances and surface finishes, but machining plastic parts does not cause as much headache as working with metals.

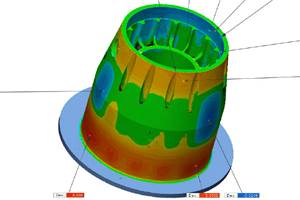

postprocessing of metal laser powder bed fusion parts often entails (1) stress relief to reduce warping, (2) removal of parts from the build plate to help establish datums for machining, (3) heat treatment to reduce microstructural variation, (4) removal of supports that reduce distortion during the build, (5) machining to reduce dimensional non-conformance, (6) secondary finishing to reduce surface effects, (7) non-destructive evaluation to avoid defects and (8) inspection to ensure dimensional integrity. Photo Credit: Tim Simpson

For metal AM parts, postprocessing is substantial, and it can easily double the cost and time it took to 3D print the part layer-by-layer. As shown in the accompanying figure, metal parts made with laser powder bed fusion typically undergo stress relief before parts are removed from the build plate. Parts are often heat treated (or undergo solution annealing, aging or hot isostatic pressing) before support removal and machining to meet tolerances. Secondary finishing operations (for example, tumbling, abrasive flow machining, electro-chemical polishing) may also be used for additional surface treatment. Finally, parts are inspected prior to their assembly or end-use. Iterations may occur throughout this process, and the duration and cost of each step will be determined by a variety of factors, including the criticality of the part, qualification guidelines and certification requirements to name a few.

We spend so much time focusing on cost reduction (and cost avoidance) that we lose sight of the fact that postprocessing helps mitigate the risks associated with layer-wise fabrication. Yes, each step adds time and cost to produce a metal AM component, but consider the alternatives:

- Stress relief helps reduce the residual stresses that accumulate in a metal part as the laser heats the material and subsequently cools during the build process it; without it, there is a risk of a part warping or even cracking once it is removed from the build plate.

- Removing parts from the build plate helps create a reference plane for establishing datums; without it, there is a risk of not being able to orient or fixture the part properly for machining.

- Heat treatment helps homogenize the microstructure and reduce material heterogeneity in the part; without it, there is a risk of the part failing due to build orientation effects or other microstructural weaknesses that can arise during the build.

- Support removal eliminates extra material that is added during the build to help reduce distortion of features on the part; without supports, there is a risk of having a build failure if the part warps too much and causes an issue when a new layer of powder is added.

- Machining helps achieve the specified geometric dimensions and tolerances; without it, there is a risk of dimensional nonconformance and rejecting the part.

- Secondary finishing operations can enhance surface properties and improve the appearance of the final part; without it, there is a risk of surface effects that may lead to premature part failure or surface flaws that detract from the intended aesthetic.

- Inspection and nondestructive evaluation help ensure dimensional and volumetric integrity; without them, there is a risk of dimensions being out of specification or missing internal defects that can cause part failure.

Because there are so many steps after the build is complete, considerable attention is spent on trying to combine, reduce or eliminate postprocessing for metal AM. For example, people often ask:

- Can we combine stress relief and heat treatment to save time? Yes, but depending on the type and extent of the heat treatment, the build plate may distort, creating subsequent challenges with part removal.

- Can we use “breakaway” supports that are easier to remove? Yes, but they may leave nubs or rough spots on the surface that will need to be removed later.

- Can we specify tolerances to avoid machining the part all over? Yes, but this necessitates an understanding and questioning of the underlying requirements that are often specified or taken as a given.

- Can we use bulk finishing processes to reduce surface roughness? Yes, but geometry and size may limit accessibility to some features depending on their location and dimensions.

- Can we avoid having to use costly X-ray computed tomography (CT) scanning to inspect every part? Yes, but only if quality control procedures have been properly implemented and maintained to ensure consistent layer-wise processing.

In short, there is still a lot of room for creativity and innovative solutions in the postprocessing of metal AM parts, and I encourage machining professionals and manufacturing experts out there to talk to an AM service provider or a company making AM parts in-house to see how they can help de-risk the process even more. While postprocessing is a cost for them, it is an opportunity to share valuable knowledge and insights to help the fledging AM industry thrive because when that happens, everyone wins.

Related Content

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreHow Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

GE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More

.png;maxWidth=300;quality=90)