PolyJet Process Speeds Injection Mold Prototyping

By 3D printing prototype mold tools, German moldmaker Hans Geiger Spritzgießtechnik reduced both the time and money required to produce them.

Injection molding tools have to withstand enormous loads, necessitating the use of strong, highly resistant metals in production and requiring an expensive and time-consuming manufacturing process. This is not a problem for mass production of injection-molded parts, as thousands of operations mean investment costs pay off shortly, but the fixed costs involved and time required to produce mold tooling are out of proportion for small batch sizes or individual pieces. As an alternative, Hans Geiger Spritzgießtechnik has been exploring 3D printing for the prototyping of molds and plastic parts, resulting in significant advantages for both the manufacturer and its customers.

Part of the Geiger Group, Hans Geiger Spritzgießtechnik is a moldmaker and injection molder of plastic parts in Nurnberg, Germany. Previously, manufacturing prototype injection mold tooling at the company took several days, a process that 3D printing has shortened to six hours. “That significant reduction in time has made it much easier to test whether an object can actually be injection molded as planned,” says Geiger Process Engineer Hans Kolb. Consequently, Geiger can quickly test whether an injection molded part made with a prototype mold is fully functional or if any improvements are necessary. This means that parts made this way can be tested for their functionality, making it also possible to choose a design and materials early on. With the accelerated process comes a greatly reduced financial risk.

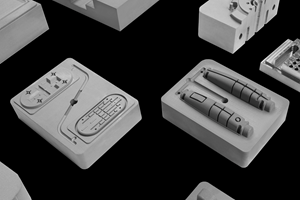

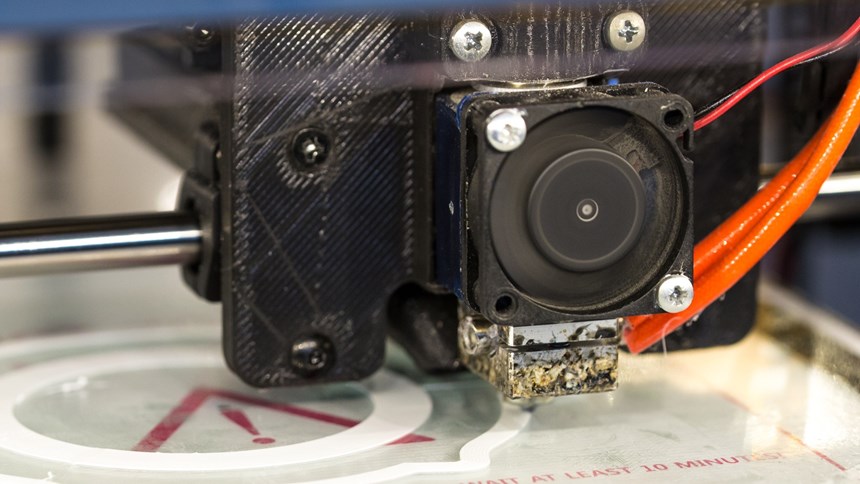

The company is using PolyJet 3D printing technology from Stratasys to create prototype injection molds without the milling and hardening steps that would be required to machine this tooling from metal. First, tiny droplets are sprayed onto a building platform and crosslinked via UV light. “We use synthetic resin for printing. The best results have been achieved with Digital ABS, especially for complex geometries,” explains Kolb. Following the UV curing, the support material is removed in a water bath or with a jet of water. If necessary, the printed workpiece is reworked by hand.

The prototype mold components can be used directly from the 3D printer with no post-curing necessary, generating less waste than milling, cutting or casting, which keeps material costs down. Components ranging to 165 cm3 can be printed, and the precision of the prints is about 1/10 mm. “Not every little detail can always be accurately represented; occasionally you have to reprocess a part mechanically,” Kolb says. “But for prototypes, the focus is not primarily on exact details, but on the option of testing different solution procedures.”

In principle, 3D printing can be suitable for all thermoplastic injection molding tools, but it may be advisable to reinforce the tooling in part with steel or aluminum. The company’s injection molding machines suitable for testing 3D-printed tooling range between 100 and 800 kN in clamping force. “Certain concessions to draft angles, radii or geometry of the parts may need to be made,” Kolb says . “After all, these are prototypes that are produced for testing and with a focus on low cost and fast manufacturing, not durable tools.” Depending on the material used, the prototype molds last about 20 cycles.

“If a tool does not meet the manufacturer’s expectations, the manufacturer has not invested large sums of money and valuable time, but can use this knowledge to make immediate improvements to the product—and re-test it a little later thanks to 3D printing,” Kolb says. According to him, this means faster processes with reduced risk, an encouraging development for the industry. The company says that by eliminating milling and hardening from the process, the user reduces the amount of time to produce a prototype from days to hours, 90 percent improvement. This lowers the cost of producing a prototype by as much as 70 percent, reducing the financial risk involved in prototype manufacturing.

Related Content

PowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More

.png;maxWidth=300;quality=90)