Keeping working systems in service is a goal for most industries, but is of special consideration for militaries. A helicopter that is grounded because of a broken part leads to time delays while a repair or replacement is made, not to mention the draw on taxpayer dollars and potential hazards to personnel working with reduced equipment. But how many more helicopters, planes and vehicles could be kept in service longer with proactive upgrades?

This was part of the motivation behind a metal 3D printed component recently produced by Allegheny Technologies Inc. (ATI), a specialty materials and complex components manufacturer. The company was tasked with building an oil collector for a fleet of legacy helicopters. Rather than replacing an existing part, this collector was a new addition to these rotorcrafts to help improve their efficiency and performance. But in the course of its production, the oil collector also came to serve as a “pathfinder part" for the customer, a component that illustrates how additive manufacturing (AM) could benefit other parts and systems in the future.

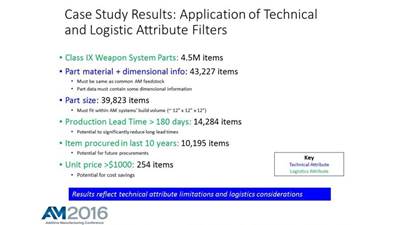

The as-printed oil collector. This component was new to the helicopter fleet but added to improve the efficiency of the rotorcrafts. Photos: Allegheny Technologies Inc.

Materials, Subtractive and Additive Manufacturing Together

Founded in 1996 with the merger of two companies, ATI is a vertically integrated global manufacturer with 50 locations worldwide and more than 50 years of experience in aerospace materials. The company produces specialty materials, including solid stock and metal powders for forgings and 3D printing, as well as advanced components. With the acquisition of 3D printing service bureau Addaero in 2018, ATI brought on direct metal laser sintering (DMLS) and electron beam melting (EBM) expertise and equipment to complement its existing machining business for parts production. Today the company does everything from material characterization through full-run manufacturing of metal components.

Richard Merlino, president and founder of Addaero, joined ATI as senior director of AM with the acquisition and runs the parts production business. He now works closely with Brian Morrison, director of AM, who has led the company’s development of titanium and nickel alloys for 3D printing. Both areas of the business inform each other; the production team can call on material expertise to select powders or create new alloys when needed, while the materials team gets insight into real customer challenges and applications from the production side. Additive production is also served and complemented by ATI's machining facility in East Hartford, Connecticut, not far from the former Addaero facility in New Britain that still houses the 3D printing capacity.

Having materials, production and machining all within one company allows ATI to bring multifaceted expertise into the product development process early on. Where additive is the right fit, ATI can guide the customer through material selection, design, finishing, inspection and more to deliver the best solution. Developing a new part for 3D printing is a chance not only to win production work, but to educate customers about the advantages and usefulness of additive manufacturing. Each part won for additive lays the groundwork for future collaboration and applications for this technology.

Start With the Problem

In the case of the oil collector, the customer was seeking performance improvement by adding a part that did not already exist within these helicopters. The part needed to be lightweight and corrosion-resistant, and it needed to fit the available space while functioning properly, but there was no legacy design to work from or to be constrained by.

The oil collector lent itself to metal additive manufacturing due to its design, relatively small scale and the low quantity needed.

"The team really got to work with a blank slate,” Morrison says, “and additive came in as a good solution for the part they had in mind.”

“The end customer was on board, and they thought it was a really good opportunity to learn how they could inject additive into their design philosophy going forward,” Merlino adds. “Everything lined up.”

With the problem defined and the stakeholders on board, ATI worked through its development process:

- Select a material. The need for corrosion resistance in the oil collector narrowed the field of possible materials to stainless steel and titanium powders; the desire for a lightweight solution led the team to Ti64 as the right choice for the oil collector.

- Iterate the design. ATI coached the customer through design for additive manufacturing (DFAM) and collaborated with them to arrive at a workable model. “What we like to do is give a basic idea of the things you can and can’t do,” Merlino says. “Then they can come back with a design and we’ll make more specific adjustments.” The final oil collector has a donut-like form with a round hole in the center; an open, tubular construction around its inner diameter; and four bolt holes plus a hose connection around the outer diameter. Importantly, the ATI machine shop and quality department were part of the conversation “from Day One,” Merlino says, ensuring that the design would be machinable and inspectable, as well as printable. The oil collector that was ultimately printed, for instance, features angular features on one side and a rectangular tab on the other — extra stock added purely for the purposes of locating and fixturing this part for machining. The bolt holes themselves are also used to locate the ID and OD in finishing and inspection.

- Choose a process. ATI has both direct metal laser sintering and electron beam melting 3D printers available, a dual capacity that gives the company insight into the relative strengths and weaknesses of each process. Both are compatible with Ti64, but manufacturability concerns led to the choice of EBM. “We showed the customer the pros and cons of both processes, and the design rules around each process,” Merlino says. “There were a fair amount of overhangs, and it was going to get tricky to support from a laser perspective.” The overhanging features plus the fairly thin walls indicated that the part would have a greater chance of success with EBM, which can generally build parts requiring smaller or larger meltpools than laser powder bed fusion with less risk of distortion due to residual stress. Plus, in EBM the unused but presintered powder can function as support for overhanging features, whereas building the oil collector with a laser-based process would have required significant sacrificial structures that might have been prohibitively difficult and time-consuming to remove.

The 3D printed oil collector includes several tabs and corners solely for the purpose of easing finish machining and postprocessing. Early input from ATI’s machine shop and quality department influences the addition of sacrificial features like these.

The oil collectors were ultimately 3D printed in a vertical orientation using electron beam melting. Following the print, the parts underwent hot isostatic pressing (HIPing) to close any porosity. After their minimal supports were removed, the parts went to an outside vendor to improve their surface finish, bringing it closer to a casting, around Ra 200. Then, they returned for machining of the four bolt holes and other finishing steps, performed in a specific sequence determined through the machining department’s early involvement. “It’s all about reducing project risk for the customer,” Morrison says of these integrated team discussions.

The oil collectors were made faster than expected, at a lower weight than the originally considered stainless steel, and proved to be effective in the helicopter fleet. From start to finish, the process to develop and manufacture these parts was about 4 months, Merlino says, but expects that a new part with this same customer could be developed in as little as 12 weeks in future, maybe less.

Solve for Specifics to Advance AM

Manufacturability was the main reason to choose metal additive manufacturing for these oil collectors, along with the limited quantities needed. It might have been possible to machine a similar solution, but this would have resulted in a longer lead time and likely a heavier part. Sheet metal forming was also feasible but would have introduced the complexities of assembly and managing a full bill of materials. EBM ultimately proved to be the best choice for delivering the lightweight component in a single piece, with minimal postprocessing, and in the small batch size required. And although this was a new part that didn’t previously exist in the system, the same line of thinking could be applied to spare and replacement parts in other legacy systems, especially those that would have previously been based on forgings or castings derived from tooling.

“There are so many different applications out there where additive can solve a problem to get these legacy platforms back to work.”

“If you think about the legacy platforms that our Department of Defense has across the board, when something comes out of service there’s a cost to that. There’s a cost to the taxpayer; there’s a cost to the warfighter,” Morrison says. “There are so many different applications out there where additive can solve a problem to get these legacy platforms back to work. An example like this can be applied elsewhere.”

Although interest in AM has accelerated in the last few years, ATI still finds that the customers who make the commitment to this technology and advance with it are those who come to it with a specific need like this oil collector. A company merely curious about AM is likely to spend a long time researching and investigating without making a real move, Morrison and Merlino say, while the companies that do pursue additive do so because they are driven to it by a specific application with no other solution, and this is where AM tends to succeed.

“When a customer says, ‘I have a component and it’s made this way today and it’s going fine but I want to explore additive,’ that’s not going to go anywhere,” Merlino says. “But when they say ‘Here’s the problem I’m trying to solve. I’ve looked at machining; I’ve considered castings and forgings. I can’t get any of this stuff to work. Can we consider additive?’ the answer is, absolutely. Situations like this where you have a problem to solve — that’s where additive is going to get good traction, and we can build on that.”

8 Cool Parts From RAPID + TCT 2021

The oil collector was featured on The Cool Parts Show, our video series highlighting innovative and interesting uses for 3D printing. Learn more and see the other parts featured: WATCH

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read MoreRead Next

8 Cool Parts From RAPID+TCT 2021: The Cool Parts Show #32

North America’s largest AM trade show resumed! Here are some of the coolest cool parts we found.

Read More3D Print or Stock? A Model for Spare Parts

3D printing provides a way of manufacturing spare parts on demand, in situ. But is it always the best solution? A new model from a Duke University professor aims to help companies make these decisions.

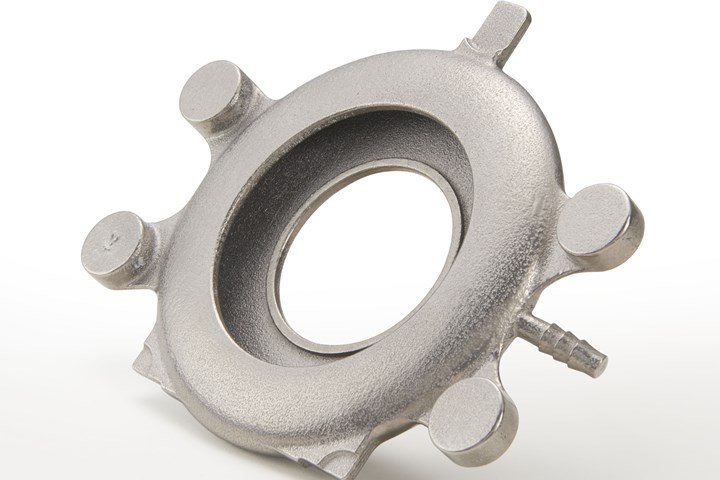

Read MoreDoD Utility Identifies Military Legacy Parts That Make the Most Sense for AM

How can the military find the best candidates for additive manufacturing out of millions of service components? It can’t without human attention, but a sorting utility helps to reduce the number to a manageable size.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)