3D Printing Hits Hollywood’s Red Carpet

Printable model project enables movie fans to engage with the movie at a new level while also inspiring students to pursue careers in science and technology.

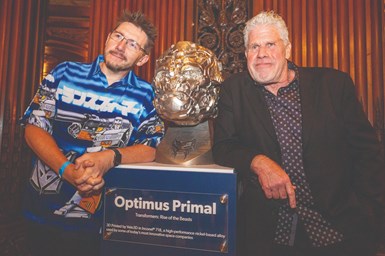

(left to right) Host of “3D Printing Nerd” Joel Telling and actor Ron Perlman, voice of Optimus Primal, on the red carpet for the premiere of “Transformers: Rise of the Beasts.”

A unique collaboration is inspiring young minds to engage with additive manufacturing (AM) by bringing the character of Optimus Primal from “Transformers: Rise of the Beasts” to life — specifically a 165-lb. Optimus Primal head 3D printed from Inconel 718.

For those not familiar with the movies, Transformers are heroic alien robot factions at war. Optimus Primal is the leader of the Maximals, a group of robotic aliens who transform into beasts and defend Earth. Inconel 718 is a nickel-based superalloy known for its superb tensile strength when subjected to extreme pressure and heat, making it ideal for high-temperature applications for parts in aerospace, defense and petrochemical industries. In bulk orders, Inconel 718 powder costs more than $65/lb.

The mastermind behind the project is David Tobin, an executive producer with a passion for 3D printing. Tobin had been on a mission to showcase the potential of AM to the world. Together with Joel Telling, they created the YouTube show “3D Printing Nerd,” where they have been traveling the globe, telling stories of engineering and manufacturing. The opportunity to engage young people with 3D printing via Hollywood began with old friends meeting at Paramount Pictures. Tobin saw this as the perfect platform to not only bring Optimus Primal to life, but to also inspire youth to pursue careers in science and technology.

Tobin reached out to Velo3D, a fully integrated AM company known for its work with advanced materials, design-for-AM software and Sapphire XC large-format laser powder bed fusion printer. Velo3D was eager to join the project and made the 3D printed Optimus Primal head as an in-kind donation that included design, materials, a print time of more than five days, depowdering and support removal. An episode of “3D Printing Nerd” captures all the details.

Bang Your Head

With the head in hand, the “3D Printing Nerd” team traveled to Toronto to meet the Hacksmith, a creator known for making working prototypes from fictional items to inspire youth to study STEM. To show the strength of the Inconel 718 head, Telling and Hacksmith dropped concrete blocks on the head and tried cutting it with a plasma gas with temperatures reaching 4,000°F. The head remained unscathed.

Connecting at Home

But the real breakthrough for young fans: Tobin teamed up with Paramount to release official 3D-printable models of Optimus Primal. They worked with the team at Printables.com to create an official profile and share two free downloadable models with the world.

Thanks to the dedication of David Tobin, Joel Telling, “3D Printing Nerd,” the team at Paramount Pictures, Velo3D, the Hacksmith, Adam Savage and Printables.com, the success of the printable model project has inspired other companies and studios to follow suit. Now, instead of just watching a movie, kids can engage with the movie at a new level while also boosting their skills. Read more at IMTS.com/Hollywood.

Read Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)