Metal Powder Works Joining Additive Manufacturing Production Campus

The 10,000-square-foot space at Neighborhood 91 will function as MPW’s main production facility, enabling it to grow production capacity by a factor of eight times.

Metal Powders Works (MPW) is joining Neighborhood 91, the additive manufacturing production campus located at the Pittsburgh International Airport. The 10,000-square-foot space will function as MPW’s main production facility, improving production capacity by a factor of eight times. The company says this move signals a significant shift to an operations focus for MPW as the company winds down fundamental development.

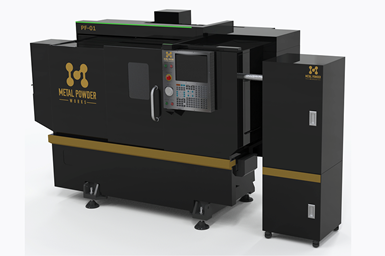

MPW says it brings the first major step change in powder production yield, cost and quality with its DirectPowder process. While the MPW Sidecar and Powder by the Hour approaches aim to change the way users access powder, MPW will market and sell primarily aluminum and copper powders from the N91 location.

The DirectPowder process has also been demonstrated for producing polymeric powders such as UHMWPE, PEEK and PEKK. With maturity, the company has outgrown its original location in Austin, Texas, and requires the additional space to expand production and grow its powder offerings.

Tom Bockius, MPW’s technical director, will oversee the construction and installation of equipment at Neighborhood 91. The company plans to be fully operational by the end of October.

Founder and CEO John Barnes sees this as a win for his team, as well as for N91 neighbors. “The concept of Neighborhood 91 was always to bring an additive manufacturing supply chain to one centralized location,” Barnes says. “We’re excited to be a part of Pittsburgh’s advanced manufacturing scene.”

Metal Powder Works says it provides high-strength aluminum and conductive copper powders, and is open to all powder production inquiries as its DirectPowder process is said to enable efficient powder production. The company is also able to produce powders tailored to the particular manufacturing process through its control of powder size and shape.

MPW was founded in 2017 by John Barnes and Chris Aldridge, veterans of the aerospace and defense markets with deep knowledge of additive manufacturing and powder production. Their experience in the space drove them to think about powder production in a new way, resulting in the MPW DirectPowder process, which produces tailorable powders in a variety of alloys.

Related Content

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

What is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

.png;maxWidth=300;quality=90)